Glass etching method

An etching and glass technology, applied in the field of glass etching, can solve the problems of serious toxicity and environmental pollution, not involving surface finish, unable to guarantee surface finish, etc., to achieve the effect of promoting contact and mass transfer, improving surface finish and improving finish.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

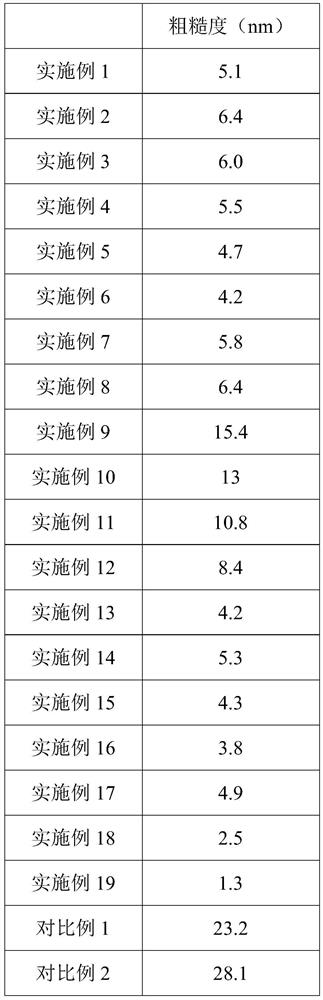

Examples

Embodiment 1

[0043] This embodiment provides a glass etching method, the glass etching method comprising the following steps:

[0044]Under the ultrasonic conditions of 75°C and 200kHz frequency, the sodium glass is etched with an etching solution; the etching solution contains ethanol with a volume concentration of 20%, and sodium hydroxide with a mass concentration of 38% in water.

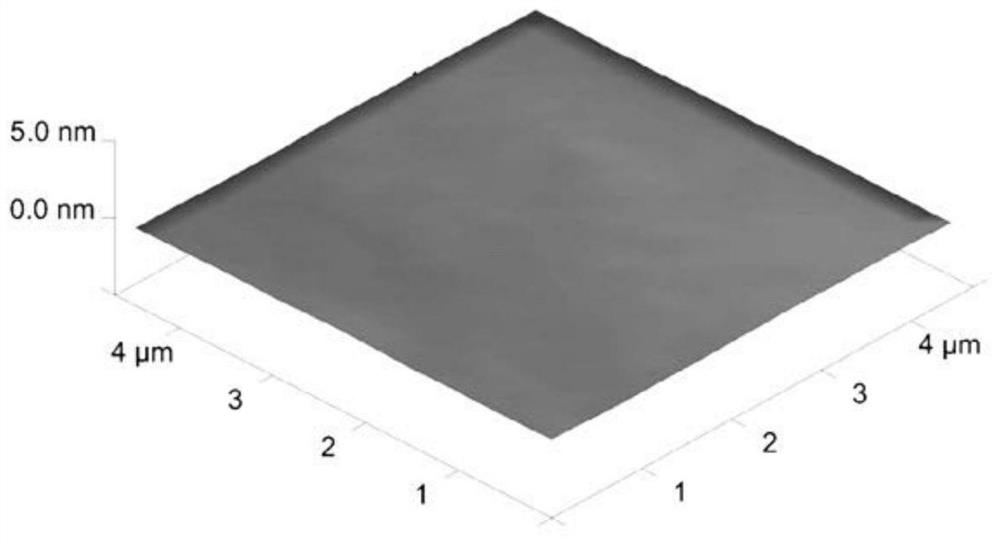

[0045] The glass surface roughness test chart after the present embodiment etching is as figure 1 shown, from figure 1 It can be seen from the figure that the etched glass surface is relatively smooth and the roughness is small.

Embodiment 2

[0047] This embodiment provides a glass etching method, which is the same as that of Embodiment 1 except that the etching solution contains ethanol with a volume concentration of 5%.

Embodiment 3

[0049] This embodiment provides a glass etching method, which is the same as that of Embodiment 1 except that the etching solution contains ethanol with a volume concentration of 10%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com