Method for quickly and mechanically deoxidizing and enriching nitrogen in closed bin

A nitrogen-enriching and nitrogen-enriching technology for deoxygenation, applied in chemical instruments and methods, inorganic chemistry, nitrogen compounds, etc., can solve the problems of long time consumption and high energy consumption of prevention and control, and achieve the effect of low deoxygenation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

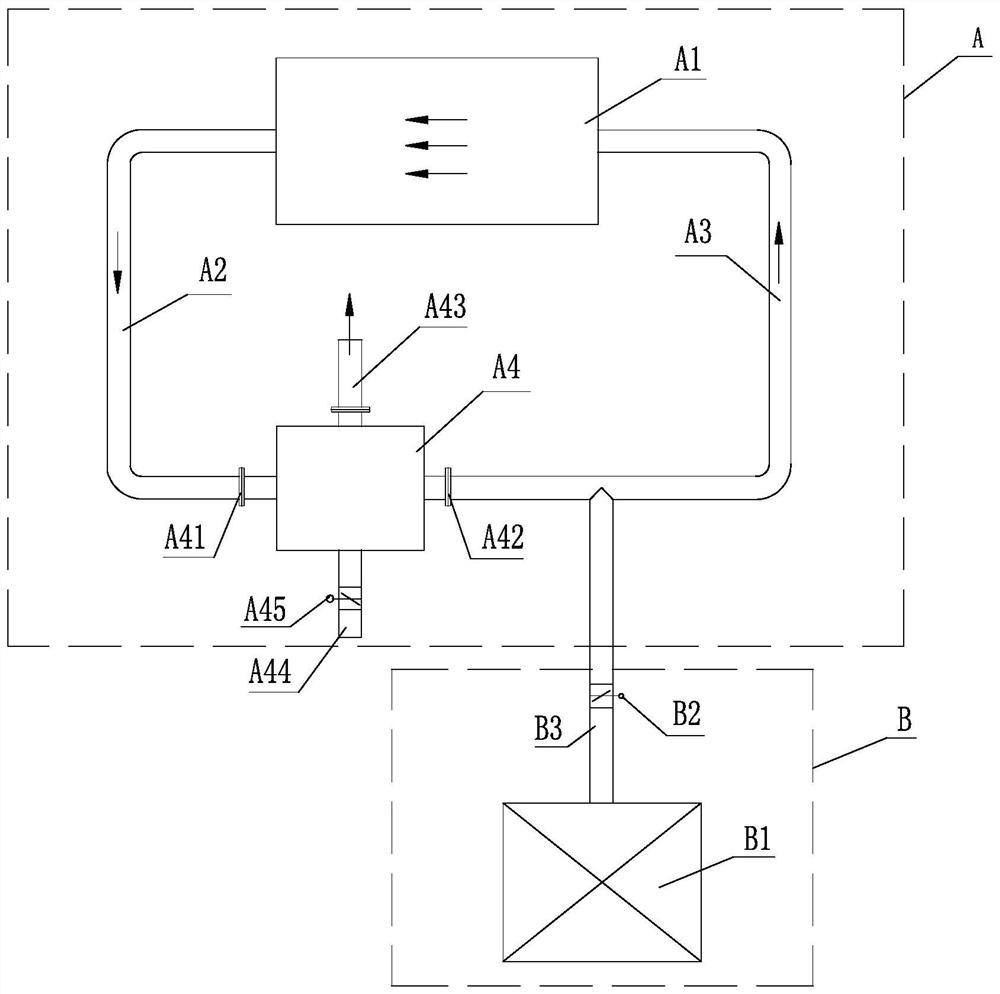

Embodiment 1

[0063] Seal the storage of grain, medicinal materials, tobacco and other agricultural products warehouses or various spaces and cabins that may breed harmful organisms to form a closed warehouse A1. In practice, the following methods are adopted for sealing:

[0064] Stacking tent: first lay a layer of plastic low film on the bottom of the stack, stack various agricultural products on the bottom film, then cover the stack with plastic tents and seal it strictly after docking with the bottom film to form a stacking tent. Six-side sealed airtight warehouse; suitable for sealing food, tobacco, and Chinese medicinal materials with outer packaging.

[0065] Whole warehouse sealing: use plastic film combined with sealant grooves or caulking glue on the doors and windows, floors, wall gaps, and pipeline wall holes of the warehouse to seal the ground plane, walls, and ceilings of the entire warehouse, or on the surface of bulk agricultural products After the plastic film is covered, t...

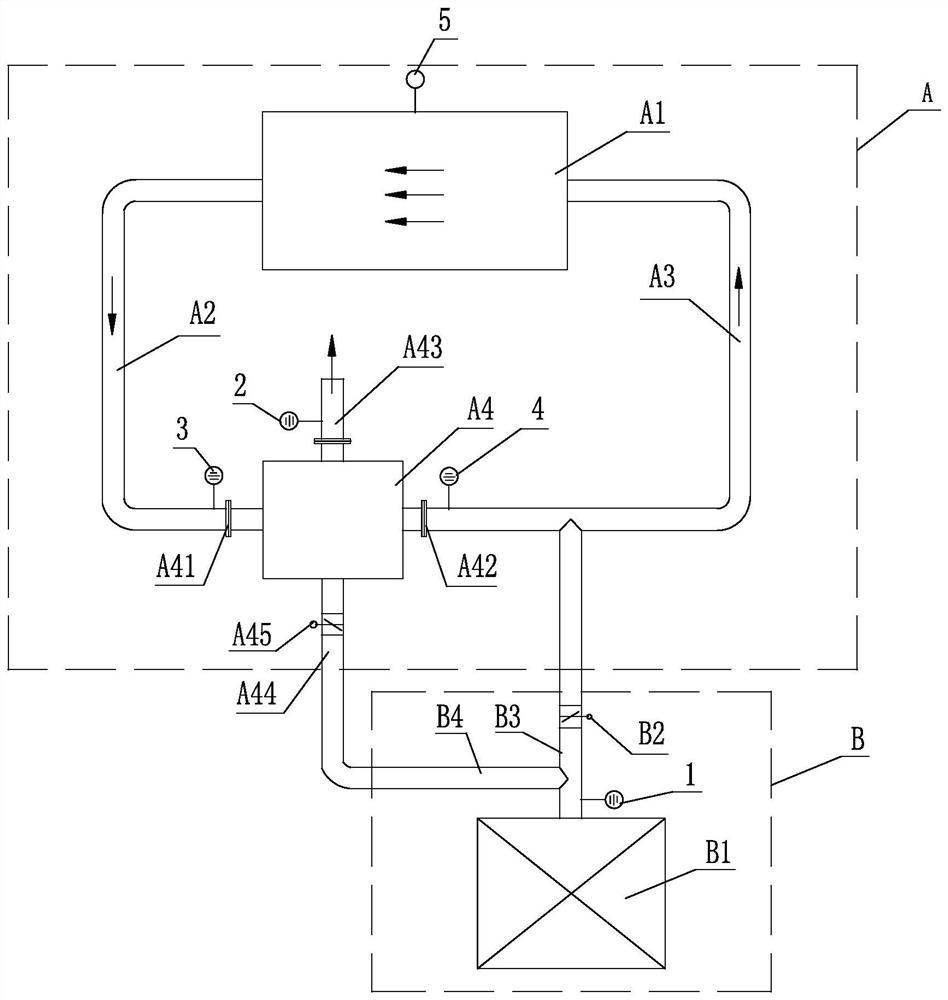

Embodiment 2

[0086] It is basically the same as Example 1, except that the nitrogen-enriched gas source B1 configured in the system air pressure equalization device B uses a high-pressure membrane nitrogen generator, the target gas produced by the equipment is nitrogen-enriched gas, and the oxygen produced is discharged as equipment tail gas Go to the external environment; you can use the membrane separation oxygen production equipment produced by Shanghai Ruiqi Gas Technology Co., Ltd.

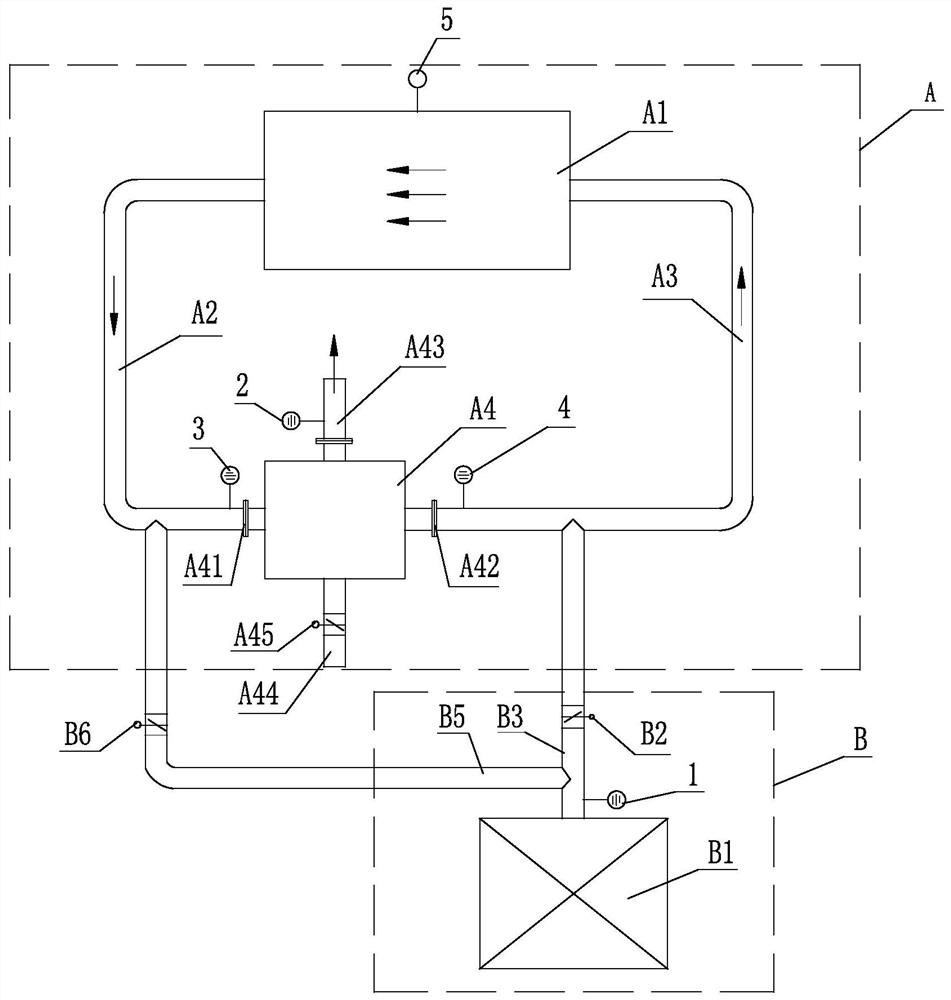

Embodiment 3

[0088] It is basically the same as Embodiments 1 and 2, except that: the nitrogen-enriched gas source B1 configured in the system air pressure equalization device B uses compressed just bottled nitrogen or a nitrogen station.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com