Double-ring oil-immersed power transformer with 1000kV high-voltage winding split

A technology for power transformers and high-voltage windings, which is applied to transformer handling devices, transformer/inductor cooling, transformer/inductor magnetic cores, etc. It can solve problems such as high transportation costs, large voltage differences, and high insulation levels of high-voltage windings. Difficulties in insulation technology, reducing the insulation level of switches, and reducing the effect of transportation height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

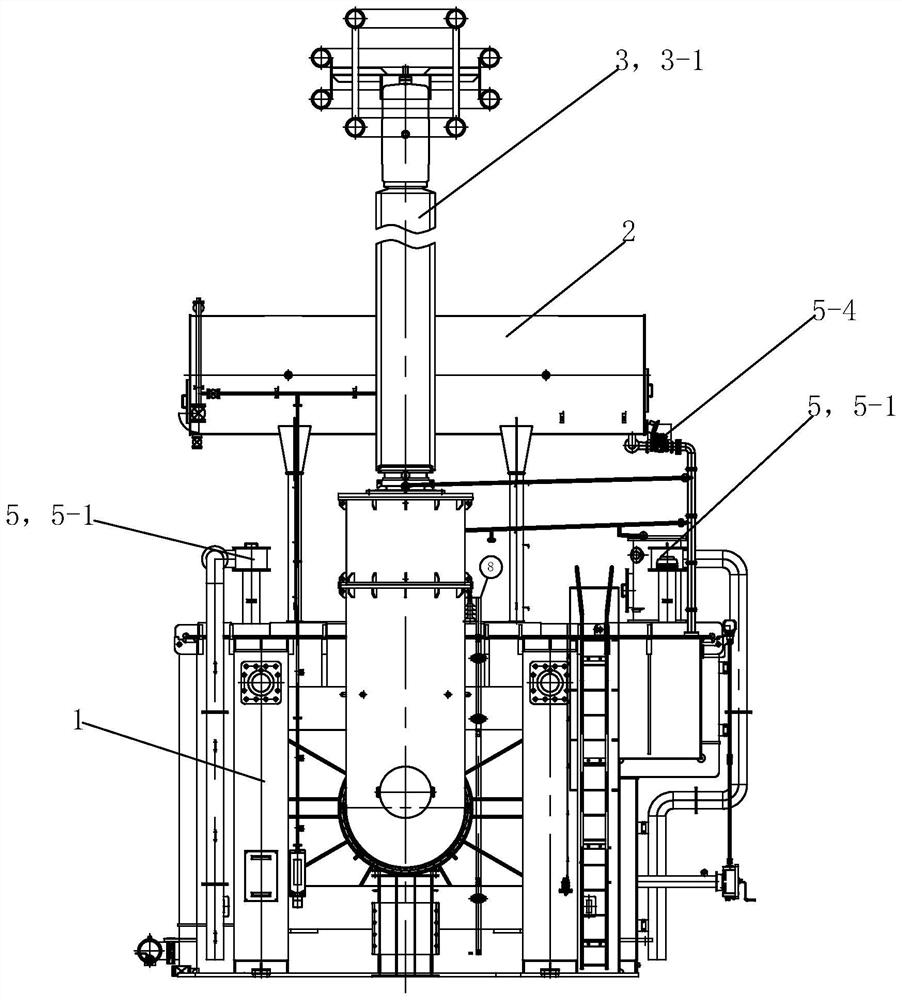

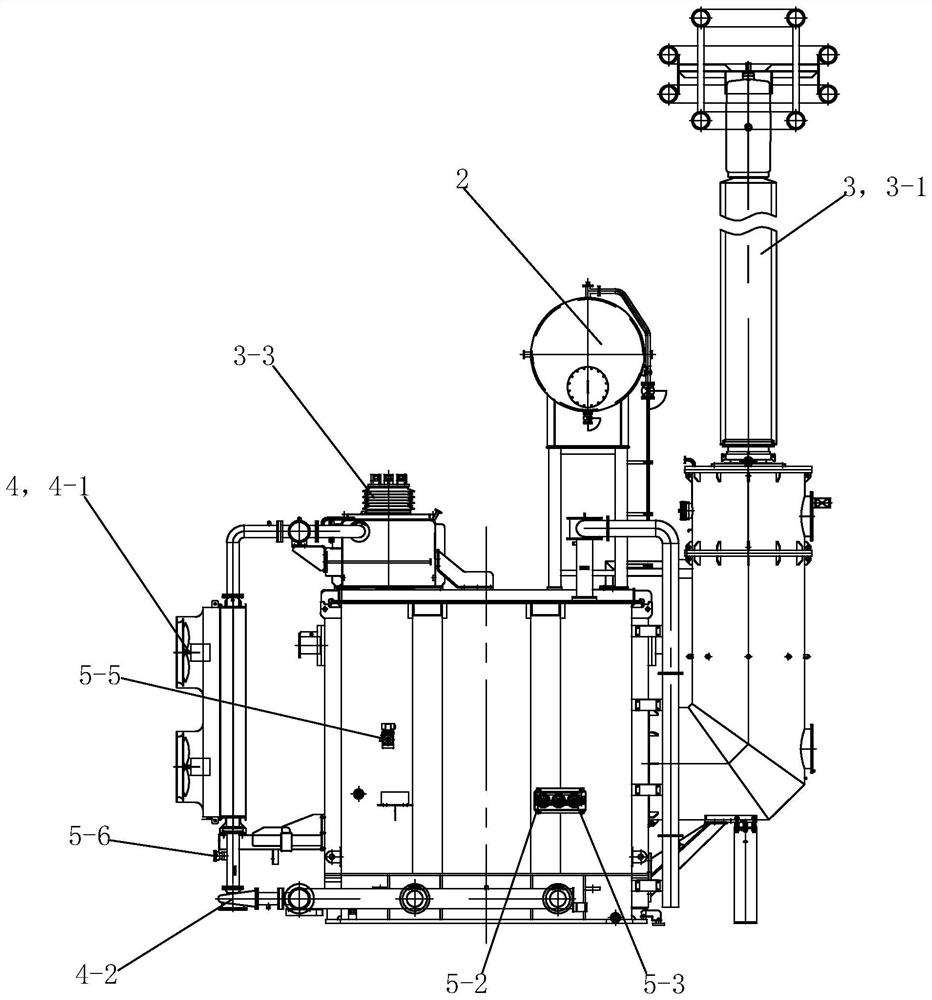

[0036] See Figure 1 to Figure 7, the 1000kV high-voltage winding split double-turn oil-immersed power transformer of this embodiment is mainly composed of an oil tank 1, an oil conservator 2, a bushing 3, a cooling device 4, a secondary protection device 5, an off-excitation tap changer 6, Composed of iron core 7, winding assembly 8 and lead wire 9.

[0037] The oil storage tank 2 is located above the oil tank 1, and the oil storage tank 2 is used to store transformer oil; the oil storage tank 2 communicates with the internal oil circuit of the oil tank 1, and the oil tank 1 is filled with transformer oil. The above is the prior art and will not be described in detail . In order to reduce the magnetic flux leakage of the fuel tank 1 and reduce the stray loss of the fuel tank 1, a magnetic shield 1-1 is provided on the inner surface of the fuel tank 1. In order to enhance the insulation effect of the fuel tank 1, a graphite shielding layer is also provided outside the magneti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com