Bridge cantilever closure section pouring equipment

A technology for closing sections and bridges, applied in bridge construction, bridges, bridge materials, etc., can solve problems such as slow construction efficiency, and achieve the effects of improving production efficiency, improving construction completion efficiency, improving construction efficiency and construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

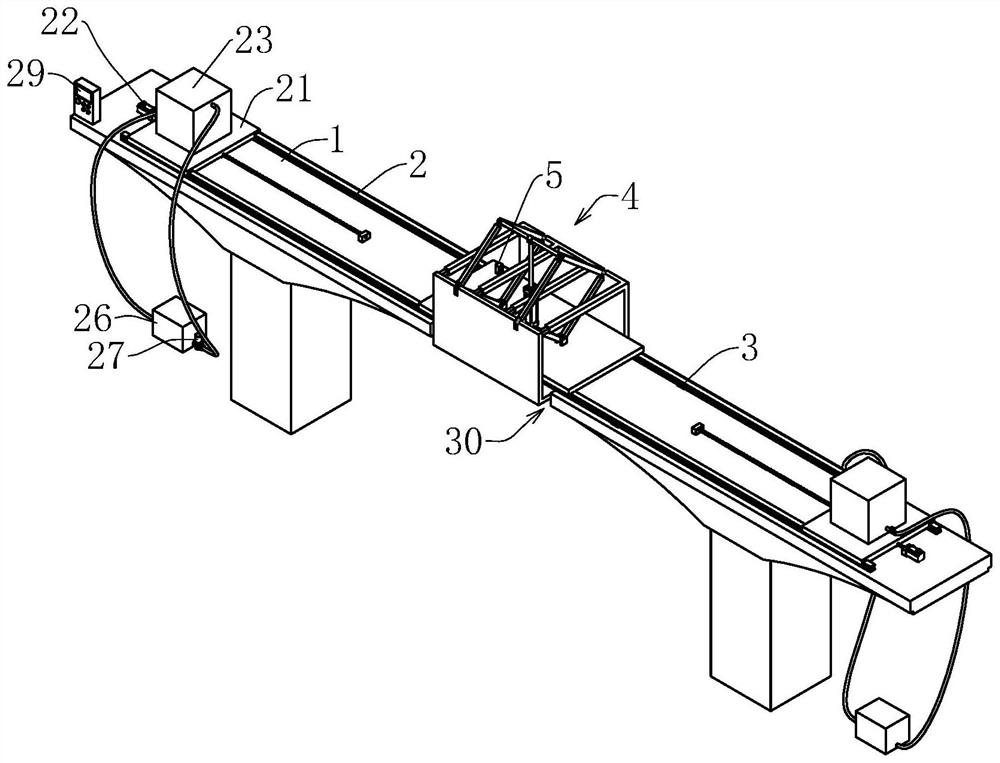

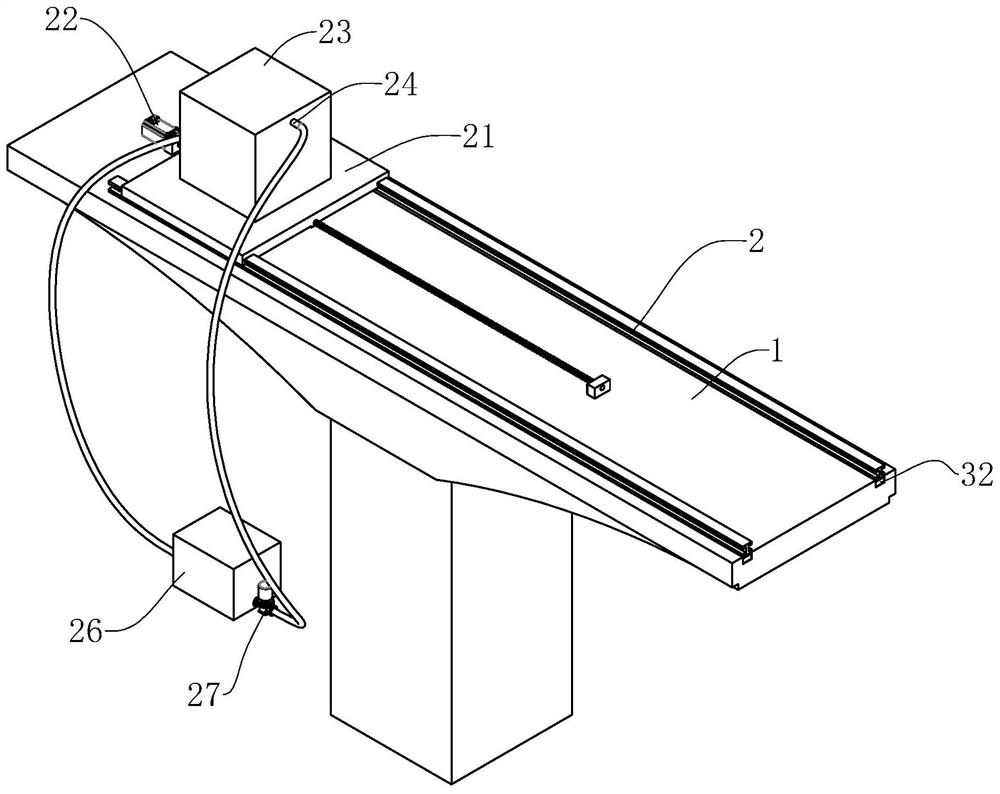

[0034] The following is attached Figure 1-4 The application is described in further detail.

[0035] The embodiment of the present application discloses pouring equipment for a cantilever closing section of a bridge. refer to figure 1 and figure 2 1. The pouring equipment for the cantilever closing section of the bridge includes moving guide rails 2 installed on the bridge 1 on both sides of the closing section 30, and the cross section of the moving guide rail 2 is I-shaped. The bridge 1 on one side of the folding section 30 is fixed with a spacer sleeve 3 for the insertion of the moving guide rail 2 . The mobile guide rail 2 is slidably connected with a suspension basket 4 , and the bridge 1 is provided with a mobile drive mechanism 5 that drives the suspension basket 4 to slide along the mobile guide rail 2 . The mobile driving mechanism 5 is a pair of servo motors on the fixed hanging basket 4, and the servo motors drive rollers through the gear box. The mobile rail...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com