Double fluorine treatment solution, preparation method and surface treatment method of magnesium alloy building formwork

A building formwork, fluorine treatment technology, applied in double fluorine treatment liquid, magnesium alloy building formwork surface treatment, preparation field, can solve the problems such as difficult to meet the technical requirements, achieve the effect of light pollution, pollution reduction and easy disposal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

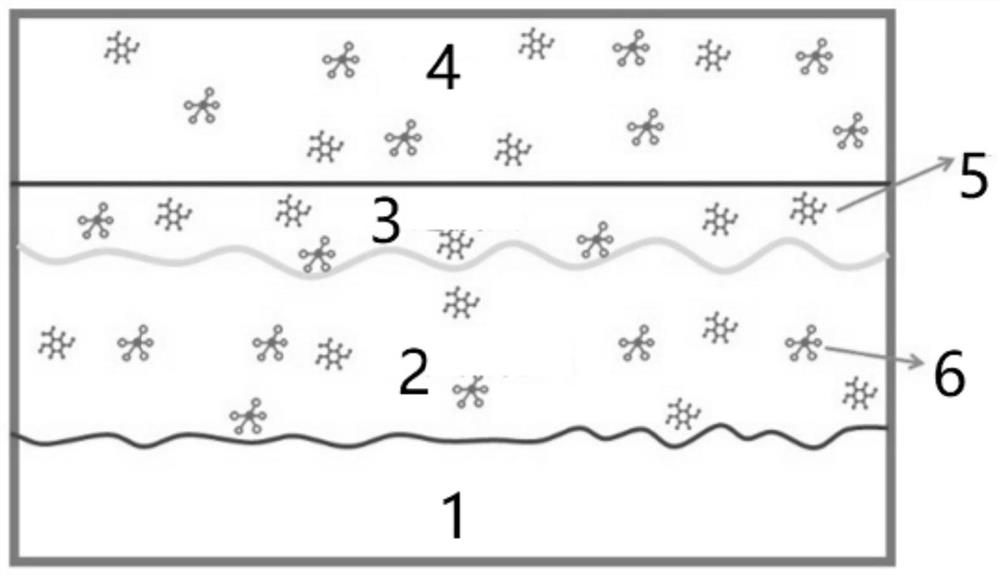

[0044] The invention provides a double fluorine treatment solution, which comprises the following components according to weight percentage: 20%-30% of inorganic fluoride, 20%-40% of organic fluorine-containing emulsion, 15%-20% of nano-silica sol, corrosion inhibitor 0.3%-0.5% of components, 0.8%-2% of silane coupling agent, 20%-43.9% of deionized water.

[0045] The inorganic fluoride is one or more of hydrofluoric acid, fluorosilicic acid, fluorotitanic acid, hypofluorous acid, hydrofluoric acid, fluorosilicate, fluorotitanate, and hypofluorous acid.

[0046] The organic fluorine-containing emulsion is an emulsion blended with a fluorine-containing water-based resin and a water-based epoxy resin, and the weight ratio of the two is 8:1-5:1; the organic fluorine-containing emulsion has self-crosslinking characteristics, and at the same time Has self-stratification characteristics;

[0047] The fluorine-containing water-based resin is polytetrafluoroethylene, polyvinylidene f...

Embodiment 1

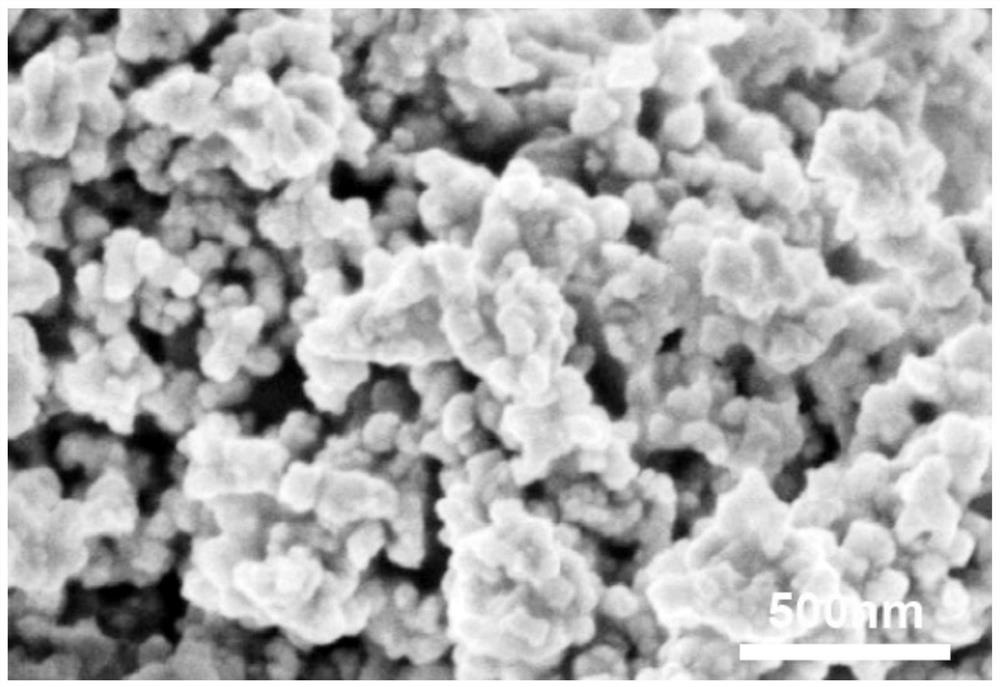

[0058] A double fluorine treatment solution, the composition (percentage by weight) includes: 22% of hydrofluoric acid, 30% of organic fluorine-containing emulsion, 16% of nano-silica sol with a particle size of 100-200nm, 0.3% of sodium metavanadate corrosion inhibitor component, γ-(2,3-epoxypropoxy)propyltrimethoxysilane coupling agent 1%, deionized water 30.7%.

[0059] Prepare the double fluorine treatment solution according to the above composition ratio, first add 24% deionized water to the container, then add 22% hydrofluoric acid, stir evenly, then add 0.3% sodium metavanadate corrosion inhibitor component, stir evenly Then add 1% of -(2,3-glycidyloxypropoxy)propyltrimethoxysilane coupling agent, simultaneously add 16% of 100-200nm particle size nano-silica sol, and add self-made organic fluorine-containing emulsion 30% while stirring at room temperature %, replenish the remaining 6.7% deionized water, and stir for 4 hours to obtain the difluoride treatment solution. ...

Embodiment 2

[0063] A double fluorine treatment solution, the composition (percentage by weight) includes: 25% hydrofluoric acid, 20% organic fluorine-containing emulsion, 20% nano-silica sol with a particle size of 100-200nm, 0.5% potassium metavanadate corrosion inhibitor component, γ-(2,3-epoxypropoxy)propyltrimethoxysilane coupling agent 2%, deionized water 32.5%. Prepare the double fluorine treatment solution according to the above composition ratio, first add 20% deionized water to the container, then add 25% hydrofluoric acid, stir evenly, then add 0.5% potassium metavanadate corrosion inhibitor component, stir evenly Then add 2% of -(2,3-glycidyloxypropoxy)propyltrimethoxysilane coupling agent, simultaneously add 20% of 100-200nm particle size nano-silica sol, and add self-made organic fluorine-containing emulsion 20% while stirring at room temperature %, add the remaining 12.5% deionized water, and stir for 5h to obtain the difluoride treatment solution.

[0064] The magnesium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

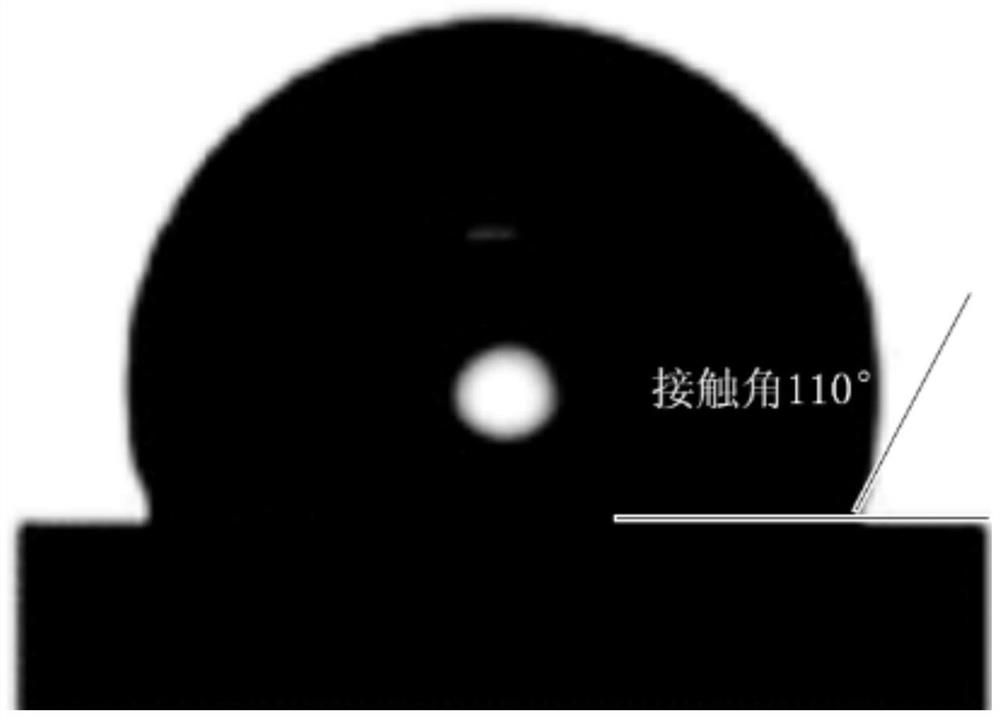

| contact angle | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com