Insulating rubber for ultrahigh-voltage direct-current cable accessory and preparation method thereof

A DC cable and insulating rubber technology, which is applied in the field of insulating rubber for ultra-high voltage DC cable accessories and its preparation, can solve problems such as complex electric field distribution, and achieve the effect of optimizing the mixing process and good electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

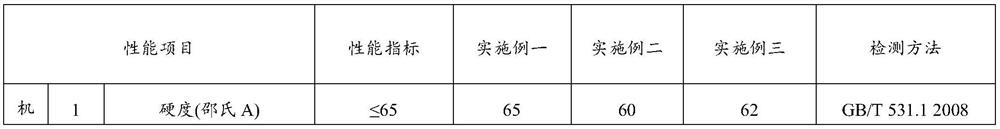

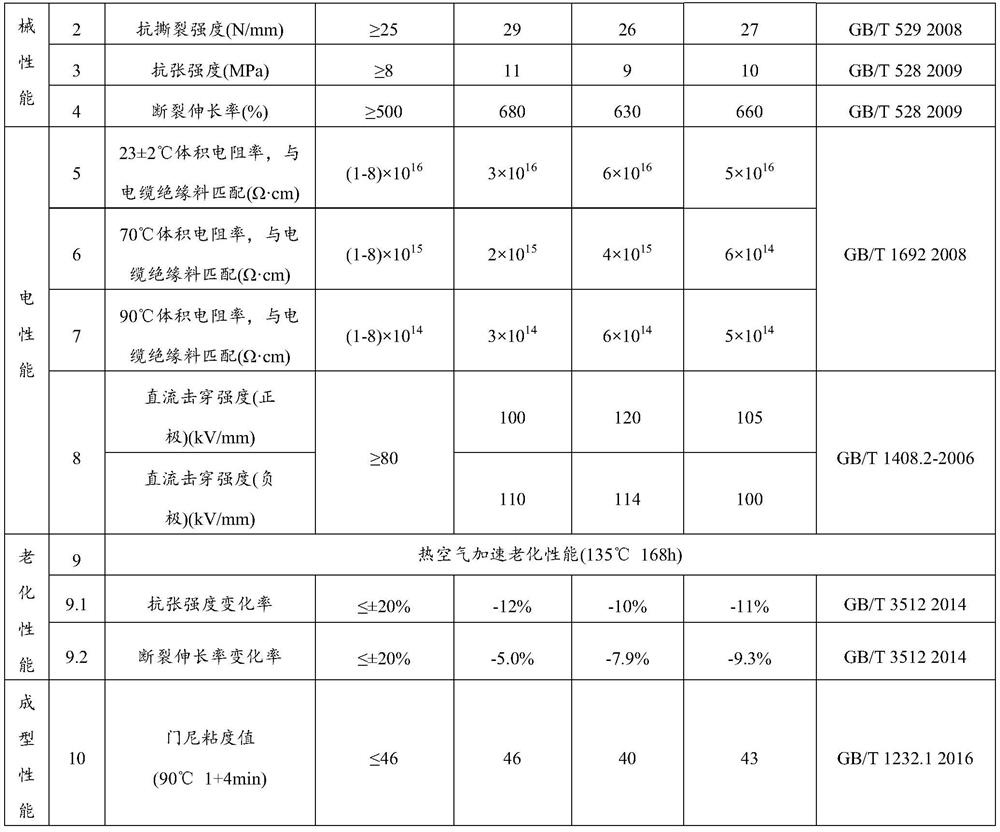

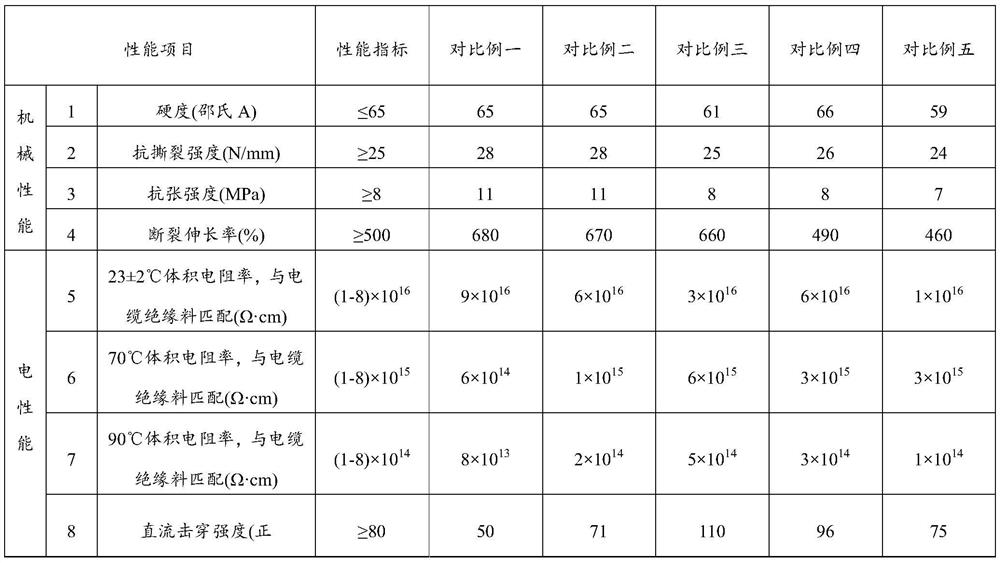

Embodiment 1

[0048] Embodiment 1 of the present invention is: an insulating rubber for ultra-high voltage DC cable accessories, and its chemical composition and parts by weight are as follows: EPDM rubber of Korean KEP210: 100 parts, zinc oxide: 5 parts, stearic acid: 1 Parts, antioxidant RD: 1 part, naphthenic oil: 15 parts, kaolin: 50 parts, talcum powder: 20 parts, bis-(γ-triethoxysilylpropyl) tetrasulfide: 4 parts, nano-oxidized Magnesium: 10 parts, Dicumyl peroxide: 3 parts, 2-Mercaptobenzothiazole: 0.5 parts, Triallyl isocyanurate: 1 part.

[0049] The preparation method of the above-mentioned insulating rubber for extra-high voltage DC cable accessories comprises the following steps:

[0050] S1: Put the formulated amount of nano-modified filler and the formulated amount of EPDM rubber into a pressurized internal mixer for 8 minutes to break the rubber and make a nano-modified masterbatch;

[0051] S2: Add the zinc oxide, stearic acid and anti-aging agent RD in the formula amount i...

Embodiment 2

[0056] Embodiment 2 of the present invention adopts the same preparation method as Embodiment 1. Embodiment 2 of the present invention is: an insulating rubber for ultra-high voltage DC cable accessories, and its chemical composition and parts by weight are as follows: EPDM rubber of Korean KEP210 : 100 parts, zinc oxide: 5 parts, stearic acid: 1 part, antioxidant RD: 1 part, paraffin oil: 7 parts, kaolin clay: 20 parts, talcum powder: 10 parts, vinyl tris(β-methoxy Ethoxy) silane: 2 parts, nano magnesium oxide: 8 parts, dibenzoyl peroxide: 2.5 parts, 2-mercaptobenzothiazole: 05 parts, triallyl isocyanurate: 15 parts.

Embodiment 3

[0058] Embodiment 3 of the present invention adopts the same preparation method as Embodiment 1. Embodiment 3 of the present invention is: an insulating rubber for ultra-high voltage DC cable accessories, and its chemical composition and parts by weight are as follows: EPDM rubber of Korean KEP210 : 100 parts, zinc oxide: 6 parts, stearic acid: 1.5 parts, antioxidant RD: 1 part, paraffin oil: 9 parts, kaolin: 40 parts, talcum powder: 15 parts, bis-(γ-triethoxy Silyl propyl) tetrasulfide: 3 parts, nano-alumina: 8 parts, dicumyl peroxide: 3 parts, 2-mercaptobenzothiazole: 1 part, triallyl isocyanurate: 1 part share.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com