Preparation method of nickel-manganese binary precursor with high electrochemical performance

An electrochemical and precursor technology, which is applied in the field of preparation of nickel-manganese binary precursors, can solve problems such as inability to produce in large quantities, and achieve the effect of improving cycle stability, improving lithium ion diffusion efficiency, and controlling the degree of compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

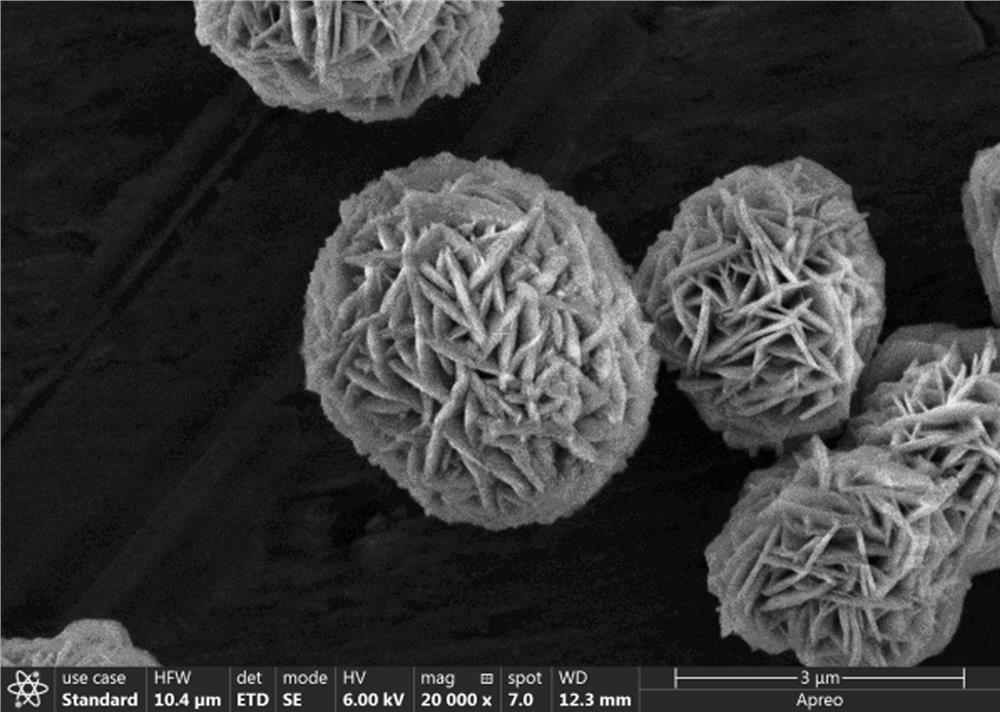

Image

Examples

Embodiment 1

[0038] This embodiment includes the following steps:

[0039] (1) Mix ammonia solution according to 1mol / L ammonia water and 1mol / L citric acid;

[0040] (2) Prepare a mixed salt solution according to the molar ratio of 2 mol / L citric acid, nickel salt and manganese salt to a sulfate molar ratio of 9:1 and the total concentration of metal salts to 3 mol / L;

[0041] (3) According to the ammonia concentration of 1mol / L and the pH value of 12.0, prepare the bottom liquid of the reaction kettle;

[0042] (4) Prepare tetrabutyl titanate solution with a concentration of 0.2mol / L as the structure control agent solution;

[0043] (5) Inject the mixed salt solution, mixed ammonia solution, structure control agent solution, and sodium hydroxide solution into the bottom liquid of the reactor, keep the temperature of the reactor at 50°C, stir at 500 rpm, and keep the nitrogen atmosphere for 8 hours to obtain the reaction slurry;

[0044] (6) The reaction slurry after step (5) was washe...

Embodiment 2

[0048] This embodiment includes the following steps:

[0049] (1) Mix ammonia solution according to 1.5mol / L ammonia water and 1.5mol / L ethylenediaminetetraacetic acid;

[0050] (2) Prepare a mixed salt solution according to the sulfate molar ratio of 3mol / L EDTA, nickel salt and manganese salt is 8:2 and the metal salt concentration is 4.5mol / L;

[0051] (3) According to the ammonia concentration of 1.5mol / L and the pH value of 12.5, prepare the reaction kettle bottom liquid;

[0052] (4) Prepare tetrapropyl titanate solution with a concentration of 0.5mol / L as the structure control agent solution;

[0053](5) Inject the mixed salt solution, mixed ammonia solution, structure control agent solution, and sodium hydroxide solution into the bottom liquid of the reactor, keep the temperature of the reactor at 60°C, stir at 600rpm, and keep the nitrogen atmosphere for 5 hours to obtain the reaction slurry;

[0054] (6) Wash the reaction slurry after step (5) with pure water at 6...

Embodiment 3

[0058] This embodiment includes the following steps:

[0059] (1) Prepare a mixed ammonia solution according to 0.8mol / L ammonia water and 0.8mol / L disodium edetate;

[0060] (2) Prepare the mixed salt solution according to the sulfate molar ratio of 0.5mol / L disodium edetate, nickel salt and manganese salt is 7:3 and the total concentration of metal salt is 2mol / L;

[0061] (3) According to the ammonia concentration of 0.8mol / L and the pH value of 11.5, prepare the bottom liquid of the reaction kettle;

[0062] (4) Prepare tetrabutyl titanate solution with a concentration of 0.8mol / L as the structure control agent solution;

[0063] (5) Inject the mixed salt solution, mixed ammonia solution, structure control agent solution, and sodium hydroxide solution into the bottom liquid of the reactor, keep the temperature of the reactor at 55°C, stir at 400rpm, and keep the nitrogen atmosphere for 8 hours to obtain the reaction slurry;

[0064] (6) The reaction slurry after step (5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com