Preparation method and application of cetyl trimethyl ammonium bromide modified composite chitosan microspheres

A technology of cetyltrimethylammonium bromide and chitosan microspheres, which is applied in the fields of chemical instruments and methods, alkali metal compounds, inorganic chemistry, etc., can solve the problems of complex preparation methods and achieve rich sources and easy operation The effect of simplicity and accelerated adsorption kinetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Disperse 0.8g of chitosan and 0.82g of ferric chloride in 50mL of deionized water at room temperature, and stir at a speed of 500r / s for 1h to form a sol; transfer the sol to a lined polytetrafluoroethylene In a 100mL hydrothermal kettle, heat at 180°C for 48h; filter the hydrothermal product, wash with 45mL of deionized water and 35mL of ethanol in turn, and dry the filter cake to obtain Fe 2 o 3 @CS microsphere;

[0031] (2) Fe obtained in step (1) 2 o 3 @CS microspheres were placed in 100 mL of an aqueous solution containing 0.6 g of CTAB and immersed at room temperature for 3 days; the separated solid matter was washed with deionized water and dried to obtain Fe 2 o 3 @CS@CTAB microspheres, named CFC-1.

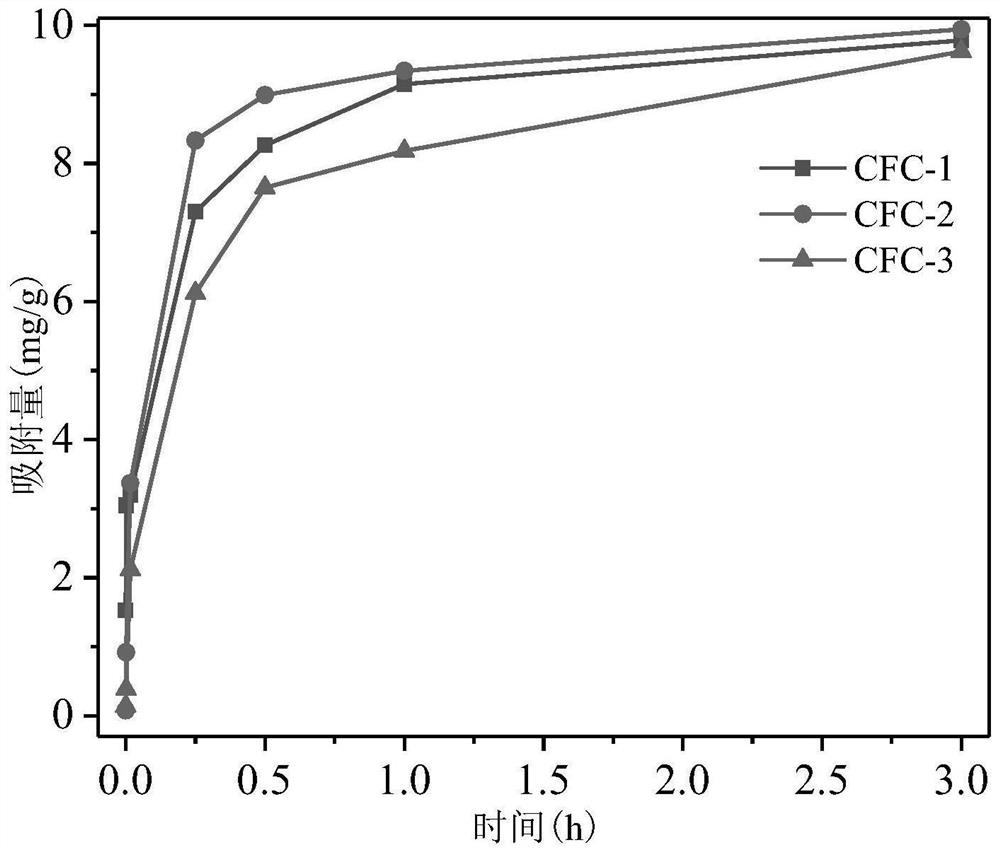

[0032] (3) Absorb the sample with 50 mL of Cr(VI) solution with an initial concentration of 10 mg / L. It is 5% hydrochloric acid solution with mass fraction to adjust the pH of Cr(VI) solution to 3, then add the CFC-1 sample of 0.05g, when the adsorption r...

Embodiment 2

[0034](1) Disperse 1.0g of chitosan and 1.0g of ferric chloride in 50mL of deionized water at room temperature, and stir at a speed of 500r / s for 1h to form a sol; transfer the sol to a lined polytetrafluoroethylene In a 100mL hydrothermal kettle, heat water at 180°C for 48h; filter the hydrothermal product, wash it with 50mL of deionized water, and then wash with 45mL of ethanol, and dry the filter cake to obtain Fe 2 o 3 @CS microsphere;

[0035] (2) Fe obtained in step (1) 2 o 3 @CS microspheres were placed in 100 mL of an aqueous solution containing 1.5 g of CTAB, and immersed at room temperature for 3 days; the separated solid matter was washed with deionized water and dried to obtain Fe 2 o 3 @CS@CTAB microspheres, named CFC-2.

[0036] (3) Use the sample to absorb 50 mL of Cr(VI) solution with an initial concentration of 10 mg / L. The pH of the Cr(VI) solution was adjusted to 3 with a 5% hydrochloric acid solution, and then 0.05 g of a CFC-2 sample was added. When...

Embodiment 3

[0038] (1) Disperse 1.5g of chitosan and 1.0g of ferric chloride in 50mL of deionized water at room temperature, and stir at a speed of 500r / s for 1h to form a sol; transfer the sol to a lined polytetrafluoroethylene In a 100mL hydrothermal kettle, heat at 180°C for 48h; after filtering the hydrothermal product, wash it with 60mL of deionized water, then wash with 45mL of ethanol, and dry the filter cake to obtain Fe 2 o 3 @CS microsphere;

[0039] (2) Fe obtained in step (1) 2 o 3 @CS microspheres were placed in 100mL of an aqueous solution containing 1.0g of CTAB, and immersed at room temperature for 3d; the separated solid matter was washed with deionized water and dried to obtain Fe 2 o 3 @CS@CTAB microspheres, named CFC-3.

[0040] (3) Use the sample to absorb 50 mL of Cr(VI) solution with an initial concentration of 10 mg / L. The pH of the Cr(VI) solution was adjusted to 3 with a 5% hydrochloric acid solution, and then 0.05 g of a CFC-3 sample was added. When the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com