High-strength composite film and preparation process thereof

A composite film, high-strength technology, applied in the direction of sustainable manufacturing/processing, synthetic resin layered products, lamination, etc., can solve the problems of insufficient surface contact protection, poor thermal compression resistance and stretching performance, and prevent stretching Fracture and delamination, the effect of uniform internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

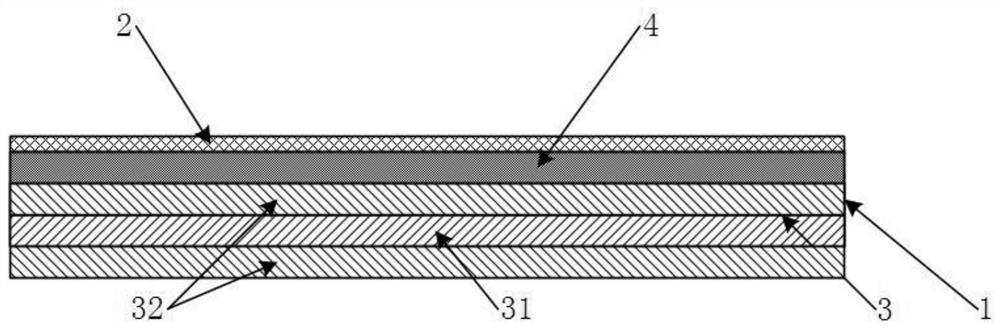

[0026]Example asfigure 1 As shown, it includes an intermediate base layer 1 and a single-sided IXPE radiation cross-linked polyethylene foamed layer 2. A TPU flexible layer 4 is provided between the structural base 3 of the intermediate base layer 1 and the single-sided IXPE radiation cross-linked polyethylene foamed layer 2. This embodiment is mainly used for a two-layer composite pallet, and the structural bases 3 of the two-layer high-strength composite film are opposed to each other, which meets the requirements of adhesive composite. It can also be used for single-layer pallet molding, and the structure base 3 itself also has the characteristics of wear resistance.

Embodiment 2

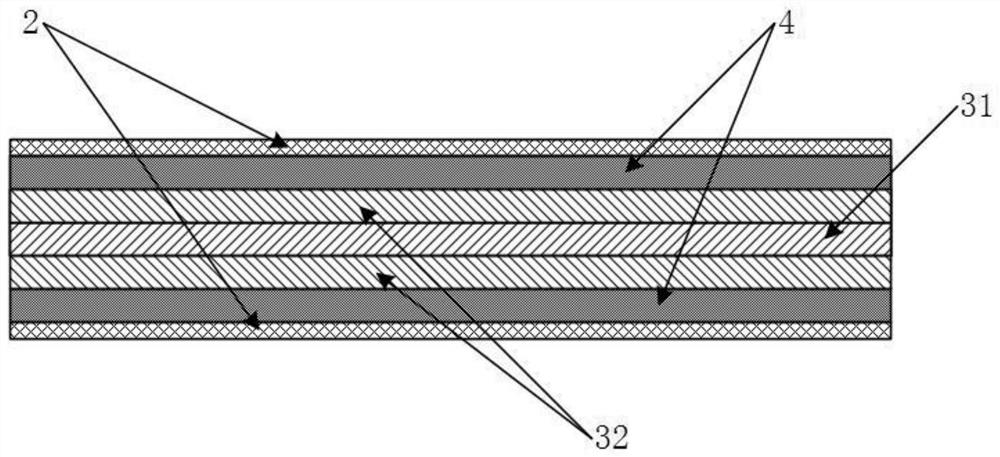

[0027]Example twofigure 2As shown, it includes a middle base layer 1 and two sides of IXPE radiation cross-linked polyethylene foamed layer 2, which is mainly used for single-layer pallet molding. Both sides of IXPE radiation cross-linked polyethylene foamed layer 2 provide surface protection.

[0028]Specific implementation process and principle description:

[0029]The IXPE radiation cross-linked polyethylene foam layer 2 has a dense foam layer, and the IXPE radiation cross-linked polyethylene foam layer 2 has excellent fracture tensile resistance, corrosion resistance, electrical insulation and other excellent characteristics, which can meet contact protection And external surface protection, prolong the service life of products.

[0030]The structural base 3 in the intermediate base layer 1 serves as a structural support and also has the characteristics of thermo-compression forming and stretching. The TPU flexible layer 4 serves as a buffer support, which can assist the IXPE radiation c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com