A kind of preparation method of cezrk/rgo nano solid solution catalyst

A technology of solid solution and catalyst, which is applied in the field of preparation of CeZrK/rGO nano solid solution catalyst, which can solve the problems of danger, insufficient energy saving and environmental protection, and inability to handle graphene, etc., and achieve the effects of environmental friendliness, reduced difficulty and danger, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

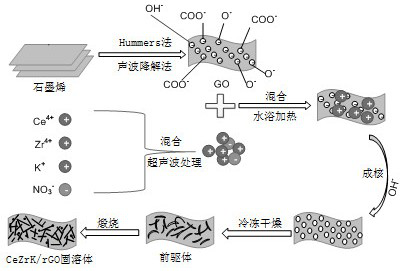

[0062] Such as figure 1 Shown, the preparation method of a kind of CeZrK / rGO nano solid solution catalyst of the present invention, concrete steps are as follows:

[0063] a. The hydrate of cerium nitrate, the hydrate of zirconyl nitrate and potassium nitrate (KNO 3 ) dissolved in deionized water to generate cerium-containing (Ce 4+ ) metal ions, zirconium (Zr 4+ ) metal ions and potassium (K + ) salt solutions of metal ions,

[0064] Cerium nitrate: potassium nitrate: zirconium nitrate=5:1:1=0.6mmol: 0.12mmol: 0.12mmol;

[0065] b. Then prepare graphene oxide, the mass ratio of graphene oxide to cerium ions is 5:1, then mix graphene oxide (GO) and deionized water, and generate graphene oxide (GO) after ultrasonic treatment for 0.5h ) solution;

[0066] c. Mix the two solutions prepared in steps a and b, and then sonicate for 0.5h;

[0067] d. Heating the mixed solution in step c for 1 h in a water bath; wherein, the heating temperature of the water bath is 80° C.;

[...

Embodiment 2

[0080] Such as figure 1 Shown, the preparation method of a kind of CeZrK / rGO nano solid solution catalyst of the present invention, concrete steps are as follows:

[0081] a. The hydrate of cerium nitrate, the hydrate of zirconyl nitrate and potassium nitrate (KNO 3 ) dissolved in deionized water to generate cerium-containing (Ce 4+ ) metal ions, zirconium (Zr 4+ ) metal ions and potassium (K + ) Salt solution of metal ions; cerium nitrate: potassium nitrate: zirconium nitrate=5:2:2=0.6mmol: 0.24mmol: 0.24mmol;

[0082] b. Then prepare graphene oxide, the mass ratio of graphene oxide to cerium ions is 5:1, then mix graphene oxide (GO) and deionized water, and generate graphene oxide (GO) after ultrasonic treatment for 0.5h ) solution;

[0083] c. Mix the two solutions prepared in steps a and b, and then sonicate for 0.5h;

[0084] d. Heating the mixed solution in step c for 1 h in a water bath; wherein, the heating temperature of the water bath is 75° C.;

[0085] e. ad...

Embodiment 3

[0095] Such as figure 1 Shown, the preparation method of a kind of CeZrK / rGO nano solid solution catalyst of the present invention, concrete steps are as follows:

[0096] a. The hydrate of cerium nitrate, the hydrate of zirconyl nitrate and potassium nitrate (KNO 3 ) dissolved in deionized water to generate cerium-containing (Ce 4+ ) metal ions, zirconium (Zr 4+ ) metal ions and potassium (K + ) Salt solution of metal ions, cerium nitrate: potassium nitrate: zirconium nitrate=5:3:3=0.6mmol: 0.36mmol: 0.36mmol;

[0097] b. Then prepare graphene oxide, the mass ratio of graphene oxide to cerium ions is 5:1, mix graphene oxide (GO) and deionized water, and generate graphene oxide (GO) after ultrasonic treatment for 0.5h solution;

[0098] c. Mix the two solutions prepared in steps a and b, and then sonicate for 0.5h;

[0099] d. Heat the mixed solution in step c in a water bath for 1 hour; wherein, the heating temperature of the water bath is 85°C

[0100] e. adding ammon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com