Flatness and appearance dimension testing equipment for sheet metal products

A technology of metal flakes and appearance dimensions, which is applied in the field of flatness and appearance dimension detection equipment of metal flake products, can solve the problems of damaged products and inconvenient cleaning, and achieve the effects of improving cleaning efficiency, avoiding damage, and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

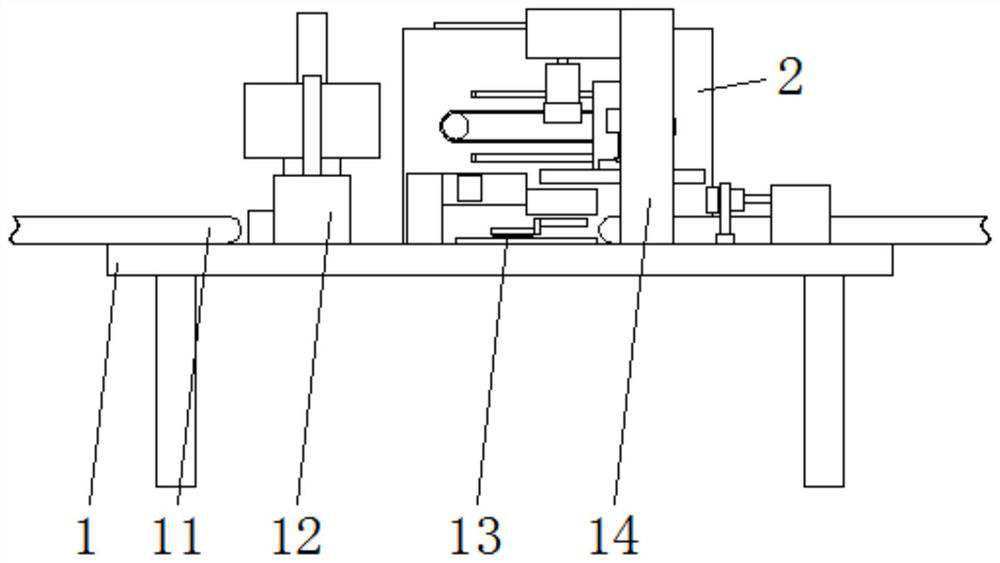

[0030] Embodiment 1: It includes a detection table body 1, a support plate 2, a fixed plate 3, a connecting block 4 and a connecting rod 5. The upper outer wall of the detection table body 1 is provided with conveyor belts 11 on both sides. For the purpose, a robot handling mechanism 12 is installed on the outer wall of the test table body 1 away from the support plate 2, a mobile detection platform 13 is installed on the outer wall of the detection table body 1 away from the robot handling mechanism 12, and the detection table body 1 is away from the mobile detection platform 13 side. A detection module mechanism 14 is installed on the outer wall.

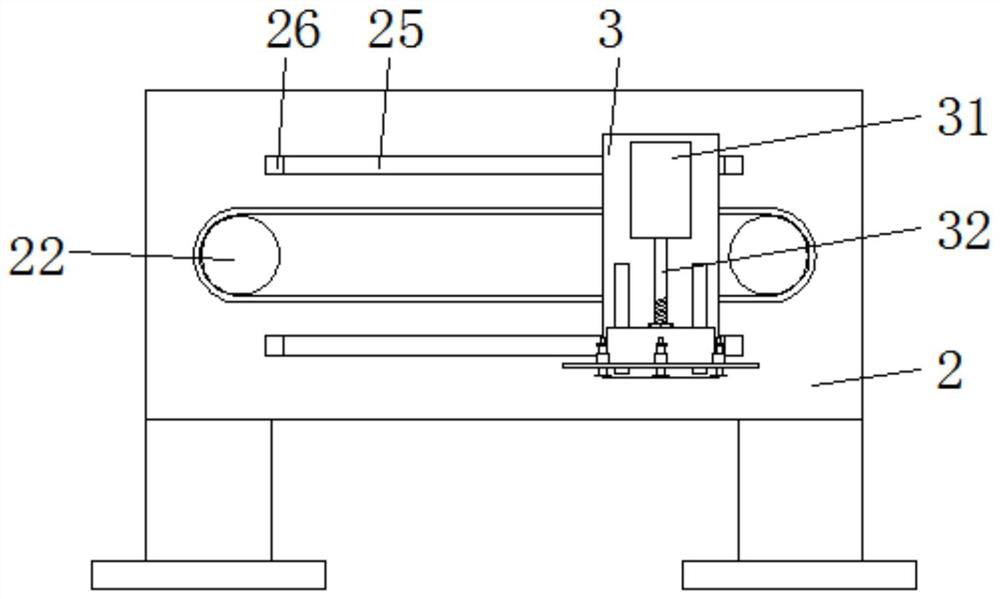

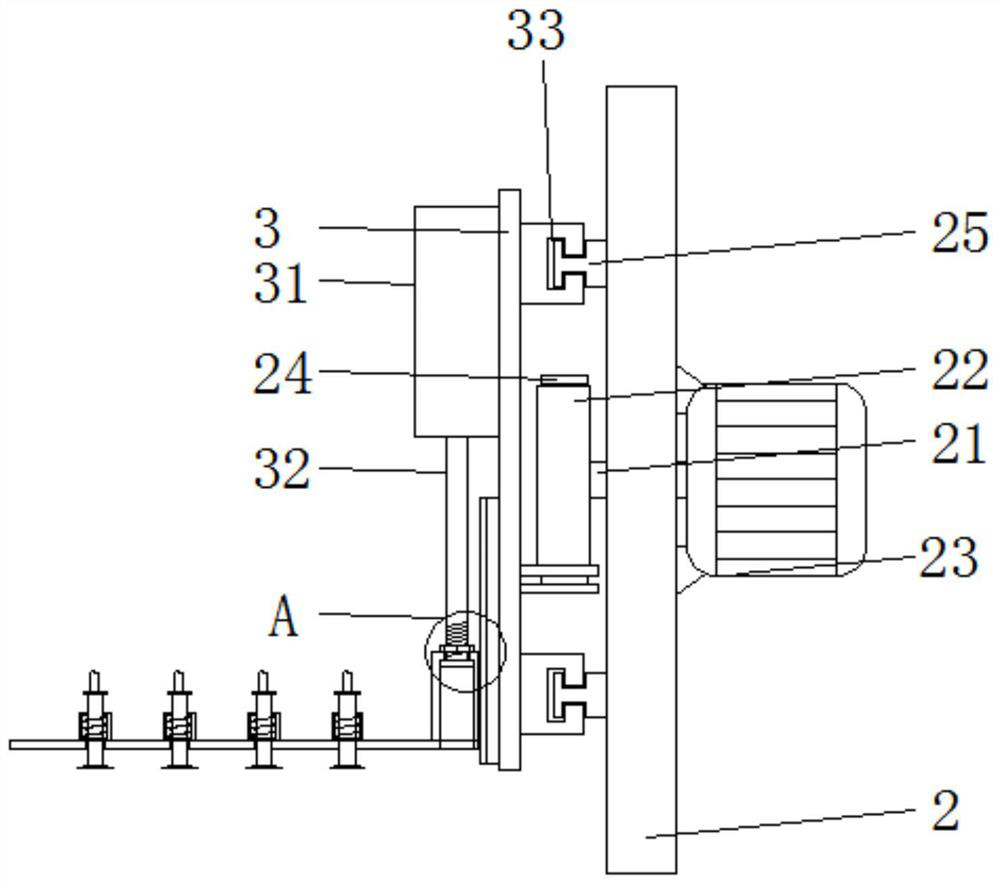

[0031] A support plate 2 is installed on the outer wall of the testing table body 1 away from the conveyor belt 11 , and a rotating shaft 21 is installed symmetrically inside the support plate 2 . A transmission wheel 22 is installed on the outer wall of one end, a motor 23 is installed on the outer wall of one end of the rotating...

Embodiment 2

[0036] Embodiment 2: It includes a detection table body 1, a support plate 2, a fixed plate 3, a connecting block 4 and a connecting rod 5. The upper and outer walls of the detection table body 1 are provided with conveyor belts 11 on both sides, and the detection table body 1 is away from the conveyor belt 11. A support plate 2 is installed on the side outer wall, a rotating shaft 21 is installed symmetrically inside the support plate 2, a transmission wheel 22 is installed on the outer wall of one end of the rotating shaft 21 through the support plate 2, and a motor 23 is installed on the outer wall of one end of the rotating shaft 21 away from the transmission wheel 22, and one side of the transmission wheel 22 is installed. A transmission belt 24 is sleeved on the outer wall, a fixing plate 3 is installed on the outer wall of one side of the transmission belt 24, a limiting groove 33 is symmetrically arranged on the outer wall of one side of the fixing plate 3, and a cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com