Energy-saving assembled machine room and dynamic loop control system thereof

A control system and machine room technology, applied in the direction of control/adjustment system, non-electric variable control, and simultaneous control of multiple variables, etc., can solve the problems of high cost, long construction period, and large pollution, and achieve the goal of reducing the proportion of power consumption Ratio, reduce the spread of noise, reduce the effect of power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

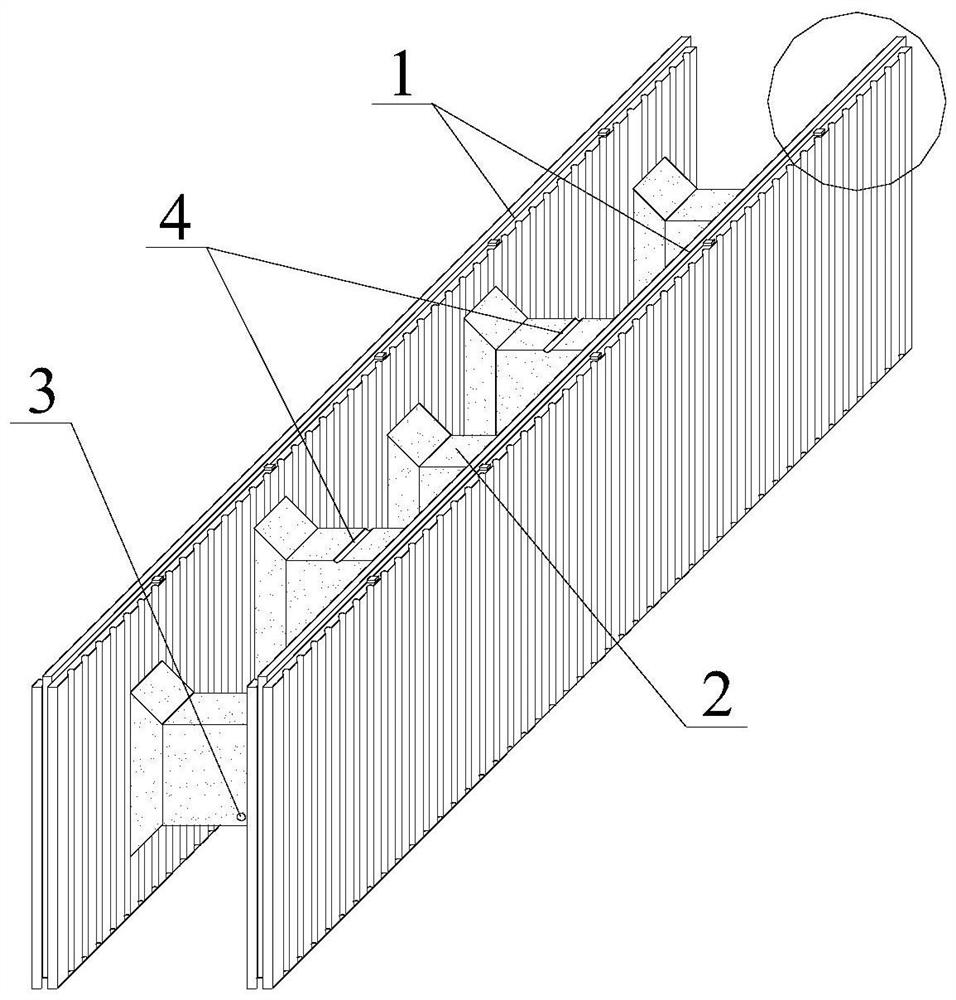

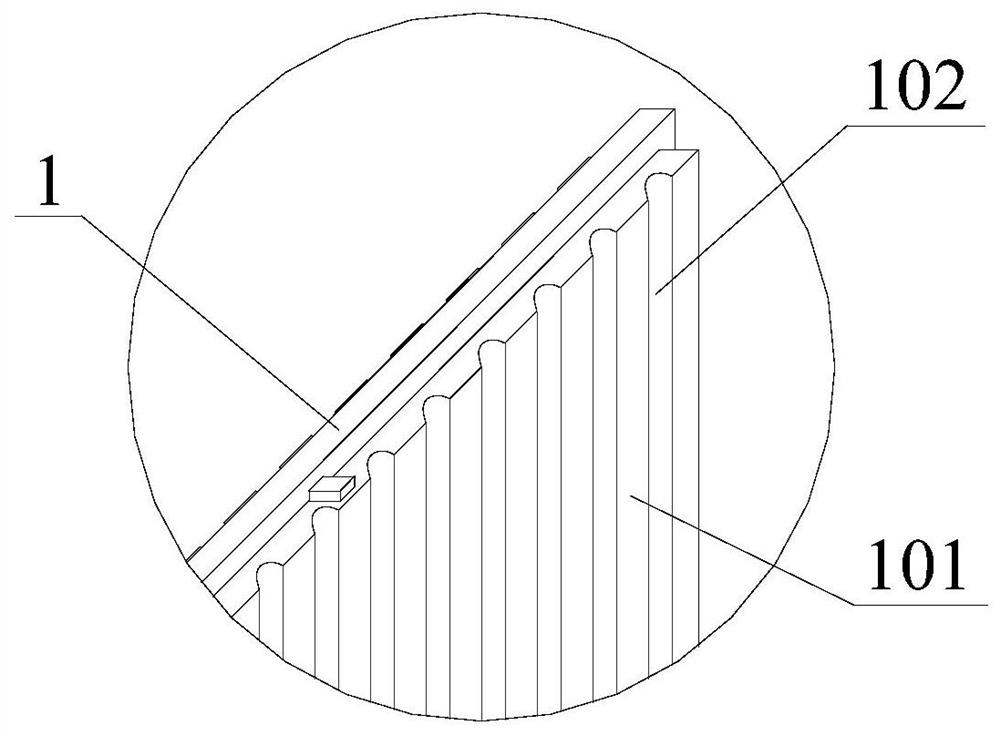

[0034] see figure 1 As shown, in the first implementation of the present invention regarding the specific structural form of the machine room wall, the machine room wall is a flat plate, and the flat plate includes a plate base 1 and an intermediate connecting column 2 fixedly arranged between the plate bases 1, wherein , the plate substrate 1 is a flat structure. In the solution of this embodiment, the flat plate is used as the wall structure arranged on the side of the energy-saving assembled machine room of the present invention, and the whole is arranged as a flat structure. Specifically, the plate is 240mm wide, 300mm high, and 900mm long. The two plate substrates 1 arranged in parallel are connected through the middle pillar 2, and the reinforcement holes reserved on the side of the middle pillar 2 can be used between each plate and the plate. 3 are horizontally connected together, or are stacked up and down through the reinforced holes 3 reserved on the upper and lower...

Embodiment 2

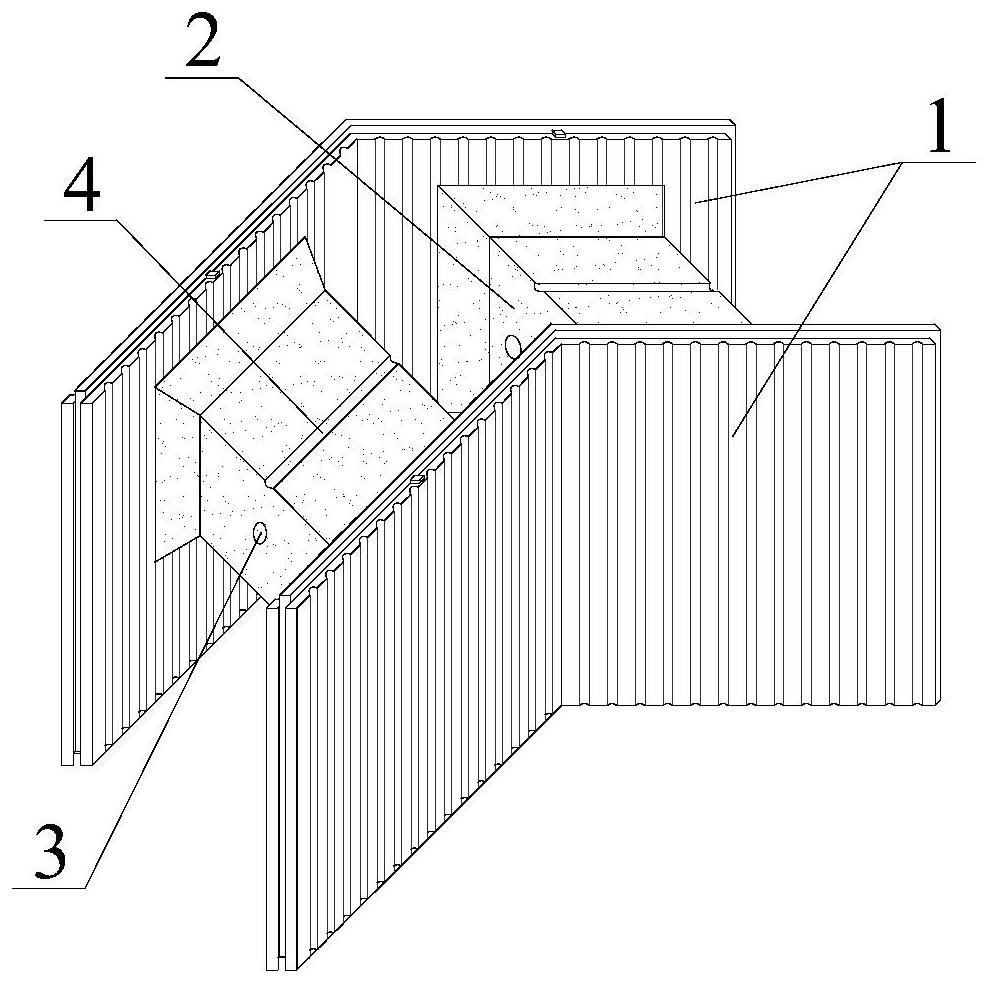

[0036] see image 3 As shown, in the second implementation of the present invention regarding the specific structural form of the machine room wall, the machine room wall is a corner plate, and the corner plate includes a plate base 1 and an intermediate connecting column 2 fixedly arranged between the plate bases 1, wherein , the plate base 1 is a flat structure and the plate base 1 forms an included angle of 90°. In the solution of this embodiment, the flat panels are used as the wall structure connecting each flat panel in the energy-saving assembled machine room of the present invention, and the whole is arranged as an L-shaped structure arranged at 90°. Specifically, the included angle of the corner plate is 90°, the width is 240mm, the equal length of both sides is 310mm, and the height is 300mm. The reinforced holes 3 reserved on the sides of the middle pillar 2 are horizontally connected together, or the reinforced holes 3 reserved on the upper and lower sides of the ...

Embodiment 3

[0038] see Figure 4 As shown, in the third implementation of the present invention about the specific structural form of the machine room wall, the machine room wall is a roof plate, and the roof plate includes a plate base 1 and a raised connecting column 5 fixedly arranged on the side of the plate base 1. The side and / or upper and lower sides of the connecting column 5 are provided with a number of reinforcement holes 3 . In the solution of this embodiment, the roof plate is used as the top wall structure in the energy-saving assembled machine room of the present invention, and the whole is also a flat plate structure. Specifically, the length and width of the roof plate are both 800mm and 120mm thick, and the side of the plate base 1 is provided with a raised connecting column 5, and the side and / or upper and lower sides of the raised connecting column 5 are reserved with reinforcement holes 3 , for the insertion of horizontal steel bars and longitudinal steel bars respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com