Ultrathin graphite paper radiating fin and manufacturing method thereof

A manufacturing method and technology of graphite paper, applied in heat exchange equipment, lighting and heating equipment, laminated components, etc., can solve the problems of inability to achieve high-end new products, waste of resources, energy consumption, etc., and achieve the protection of scarce graphite resources, improving service life, and reducing the cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

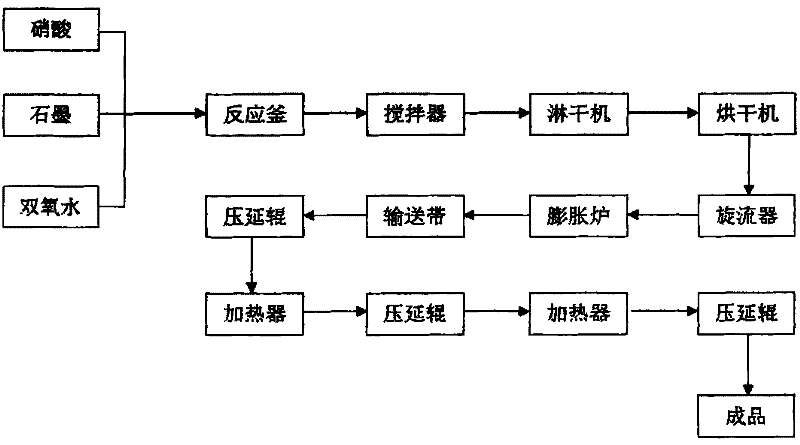

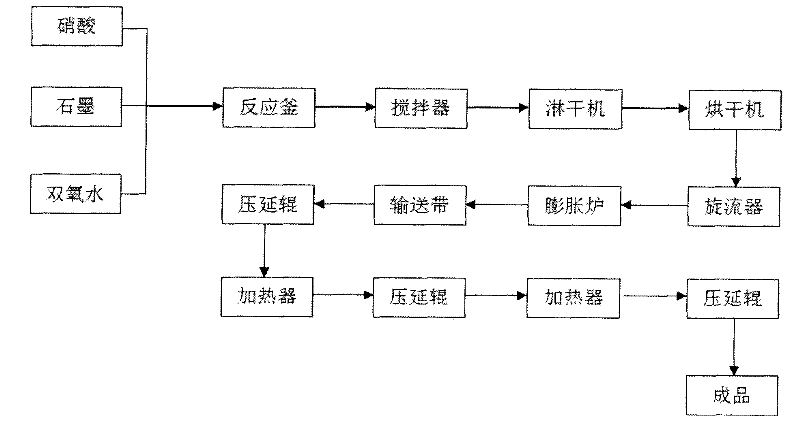

Method used

Image

Examples

Embodiment 1

[0026] The present invention adopts nitric acid+hydrogen peroxide to process graphite, and the proportioning ratio of nitric acid, hydrogen peroxide and graphite is 3:0.3:1, graphite is first added in the reaction kettle, and after reaching the reaction temperature of 16°C, the addition of nitric acid with a mass fraction of 90% and a concentration of 20 % hydrogen peroxide, graphite under the action of nitric acid and hydrogen peroxide, the temperature is controlled at 16 ° C, the reaction time is 1.5 hours, stirring to generate an expandable graphite product with an expansion rate of 300 times, dehydration by a dehydrator for 30 minutes, and drying in a drying oven for 30 minutes hours later.

[0027] Machine screening and classification, so that the expandable graphite on the 300 micron sieve accounts for 90%;

[0028] The processed expandable graphite enters the expansion furnace with a temperature of 950 degrees through the cyclone for heating and expansion, and the expan...

Embodiment 2

[0032] The present invention adopts nitric acid+hydrogen peroxide to process graphite, and the proportioning ratio of nitric acid, hydrogen peroxide and graphite is 3:0.3:1, graphite is first added in the reaction kettle, and after reaching the reaction temperature of 16°C, the addition of nitric acid with a mass fraction of 70% and a concentration of 50% % hydrogen peroxide, graphite under the action of nitric acid and hydrogen peroxide, the temperature is controlled at 16 ° C, the reaction time is 1.5 hours, stirring to generate an expandable graphite product with an expansion rate of 300 times, dehydration by a dehydrator for 30 minutes, and drying in a drying oven for 30 minutes hours later.

[0033] Machine screening and classification, selecting expandable graphite on a sieve with a particle size of 300 microns accounts for 90%;

[0034] The processed expandable graphite enters the expansion furnace with a temperature of 950 degrees through the cyclone for heating and ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com