Rock breaking construction method of underwater deep foundation trench

A construction method and rock-breaking technology, which is applied in water conservancy projects, sea area projects, earth movers/shovels, etc., can solve the problems of large underwater environment impact, low precision, and low rock strength, and achieve safe and reliable operation , implement the effect of high precision and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present invention are described in detail below in conjunction with accompanying drawings:

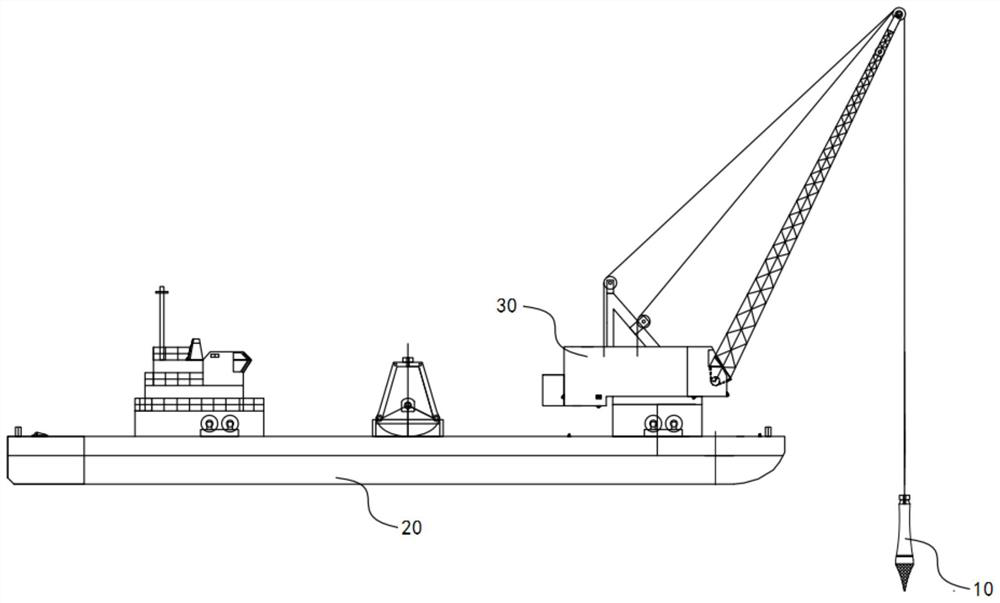

[0030] Such as Figure 1 to Figure 3 As shown, a rock-breaking construction method for underwater deep foundation trenches comprises the following steps:

[0031] S1: Determine the depth and sound velocity profile information of the dredging construction area;

[0032] S2: The construction ship accurately locates the dredging construction area through the positioning system;

[0033] S3: The construction ship excavates the soil cover layer in the dredging construction area;

[0034] S4: determine the distribution of rocks in the dredging construction area by secondary measurement;

[0035] S5: set rock drilling point 40 and rock drilling times, carry out rock breaking construction by rock breaking hammer 10;

[0036] S6: the broken rock is removed;

[0037] S7: Measure the dredging construction area, if the measurement result meets the acceptance criteria...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com