Preparation method of low-cost anti-segregation anti-aging modified asphalt

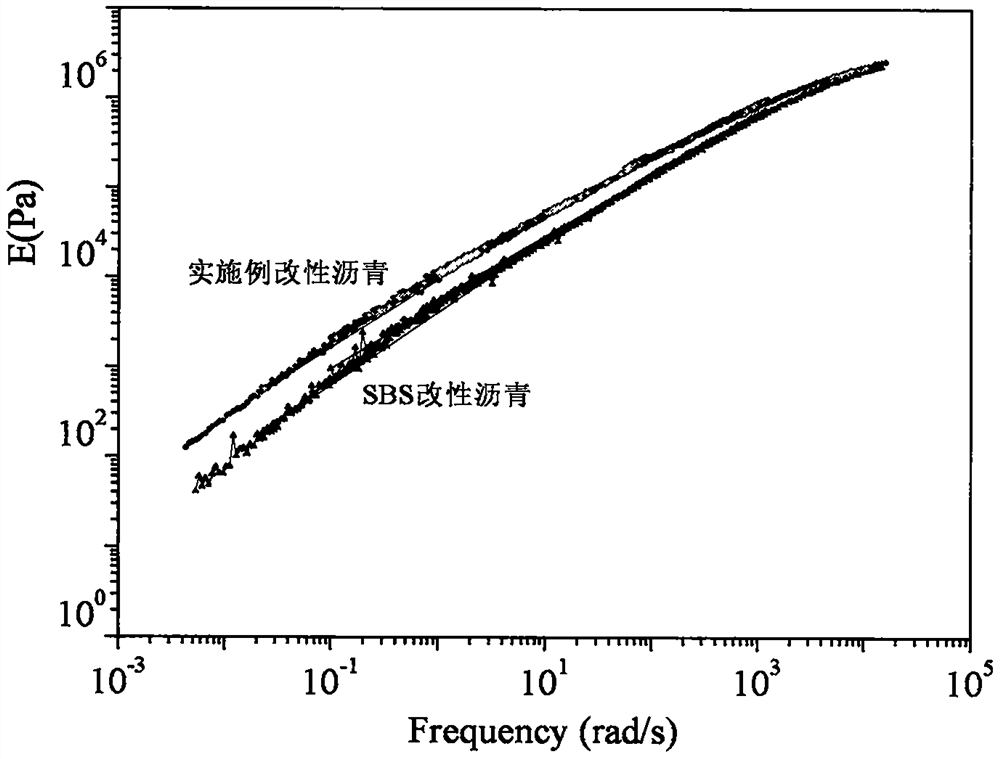

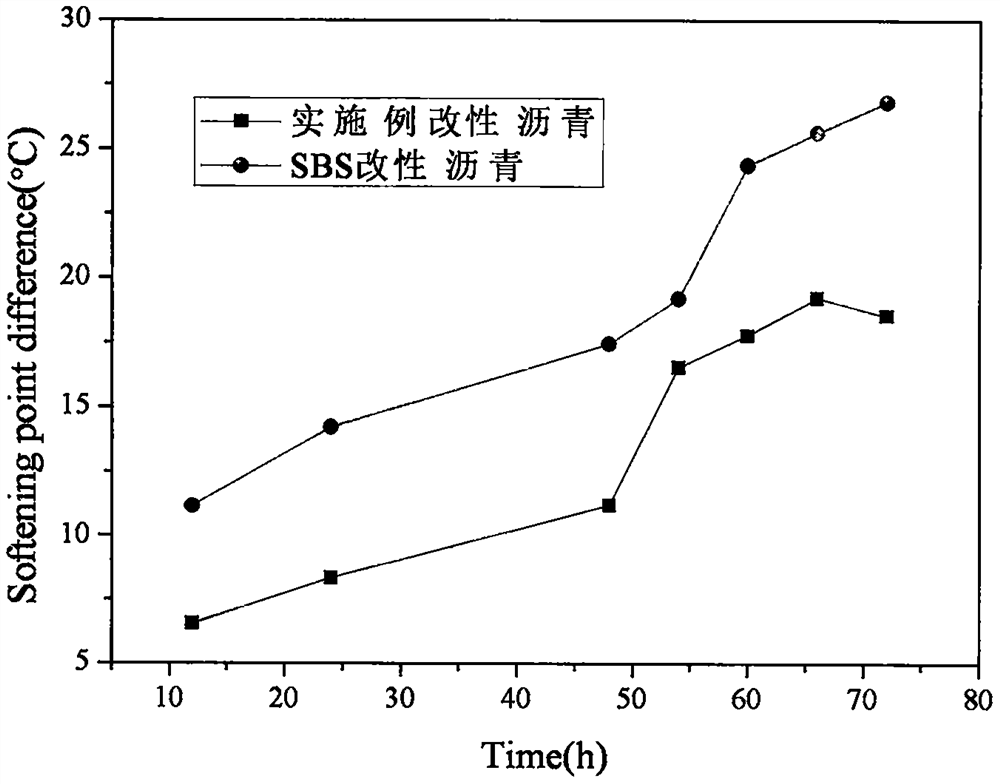

A technology of modified asphalt and its production method, which is applied to building components, building thermal insulation materials, buildings, etc., can solve the problems of easy segregation, short storage period, high cost of modified asphalt, and improve anti-aging ability and storage stability. , The effect of improving storage stability and reducing the amount of SBS

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Formulated according to the mass percentage of petroleum asphalt:

[0026] 90#A grade petroleum asphalt quality 1kg, styrene-butadiene-styrene triblock copolymer (SBS) 2.5%~2.8%, polyphosphoric acid (PPA) 0.5%~0.75%, stabilizer 0.05%~0.1 %, rubber oil 1.5% to 1.8%.

[0027] The described polyphosphoric acid of the present embodiment selects industrial grade 105% polyphosphoric acid as the test raw material, wherein H 3 PO 4 About 104.0~106.0%, P 2 o 5 ≥76.0%, C1≤0.001%, Fe≤0.002%, As≤0.008%; the main component of the stabilizer is diaryl disulfide, the density is 1.2g / cm3, and the active ingredient is greater than 99.5%; the rubber oil mainly The ingredients are aroma and colloid.

Embodiment 2

[0029] Formulated according to the mass percentage of petroleum asphalt:

[0030] 90#A grade petroleum asphalt quality 1kg, styrene-butadiene-styrene triblock copolymer (SBS) 2.6%, polyphosphoric acid (PPA) 0.5%, stabilizer 0.05%, rubber oil 1.5%.

[0031] The described polyphosphoric acid of the present embodiment selects industrial grade 105% polyphosphoric acid as the test raw material, wherein H 3 PO 4 About 104.0~106.0%, P 2 o 5 ≥76.0%, Cl≤0.001%, Fe≤0.002%, As≤0.008%; the main component of the stabilizer is diaryl disulfide with a density of 1.2g / cm 3 , the active ingredient is greater than 99.5%; the main components of the rubber oil are aromatic components and colloids.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com