High-performance pre-dispersed silicon mortar concrete and preparation method thereof

A technology of silica mortar and pre-dispersion, which is applied in the application field of high-activity auxiliary cementitious material - silica fume, which can solve the problems of poor workability of silica mortar concrete, poor dispersion effect of silica fume, and low steam-cured demolding strength. Achieve the effects of saving material cost and energy consumption, shortening dispersion time, and high degree of dissociation and dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

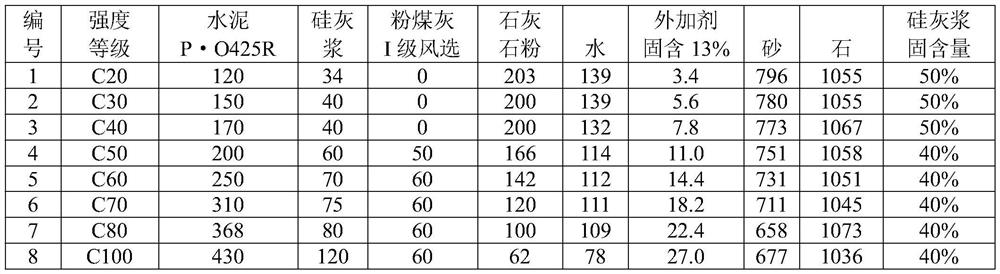

[0024]The mixing ratio of C20-C100 fluidized high-performance pre-dispersed silica mortar concrete is shown in Table 1. The preparation method is:

[0025]A high-performance pre-dispersed silica mortar with a solid content of 50% was prepared according to the following composition: 1 part of silica fume and 1 part of water; a high-performance pre-dispersed silica mortar with a solid content of 40% was prepared according to the following composition: 1 part of silica fume and 1.5 parts of water. The composition of the functional dispersants of the above two silica mortars are: 0.001 parts of diethylene glycol butyl ether; 0.02 parts of potassium water glass with modulus of 2.0; and 0.000002 parts of fluorocarbon interfacial tension regulator. Measure the functional dispersant and water according to the above ratio, dissolve and prepare and measure the functional dispersion, add the above proportion of silica fume to the functional dispersion; for the mixture of silica fume and the funct...

Embodiment 2

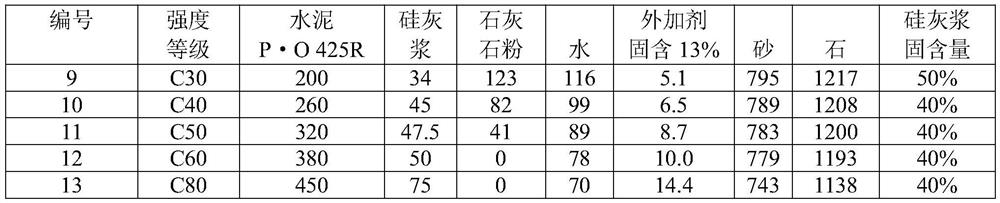

[0030]Table 2 shows the mixing ratio of C30-C80 semi-dry hard high-performance pre-dispersed silica mortar concrete for precast components. The preparation method is as follows:

[0031]A high-performance pre-dispersed silica mortar with a solid content of 50% was prepared according to the following composition: 1 part of silica fume and 1 part of water; a high-performance pre-dispersed silica mortar with a solid content of 40% was prepared according to the following composition: 1 part of silica fume and 1.5 parts of water. The composition of the functional dispersants of the above two silica mortars is: 0.001 part of dipropylene glycol methyl ether; 0.03 part of sodium bicarbonate; 0.000001 part of fluorocarbon interfacial tension regulator. Measure the functional dispersant and water according to the above ratio, dissolve and prepare and measure the functional dispersion, add the above proportion of silica fume to the functional dispersion; for the mixture of silica fume and the fun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flame retardant | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com