Modified calcium oxide expansion agent for shrinkage-compensating concrete and preparation method thereof

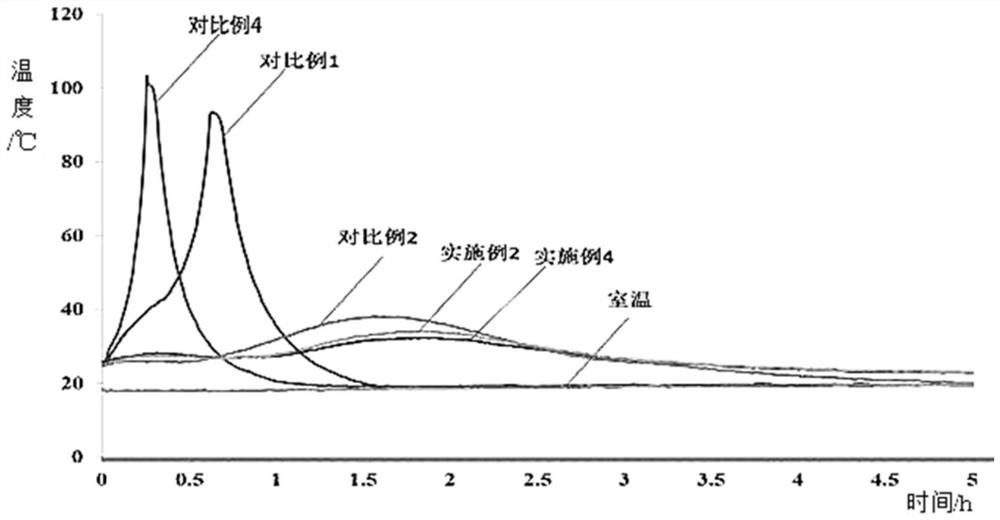

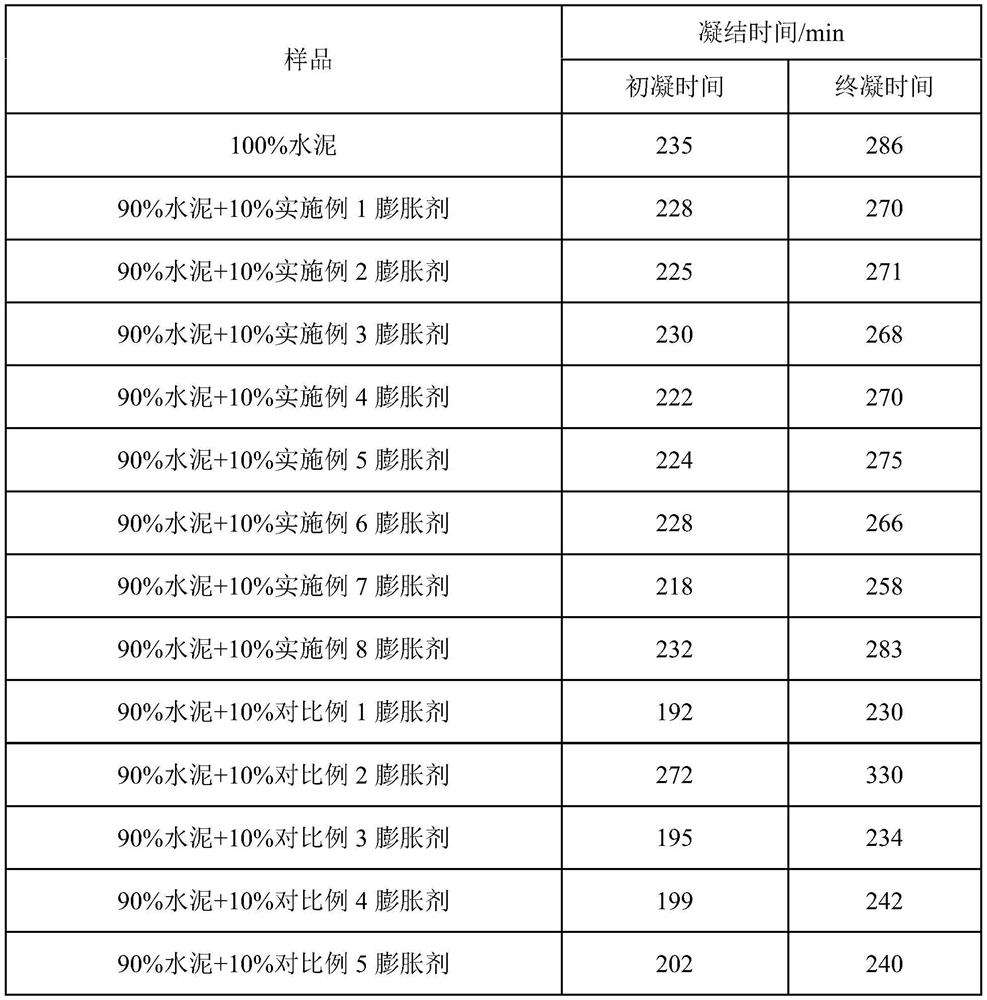

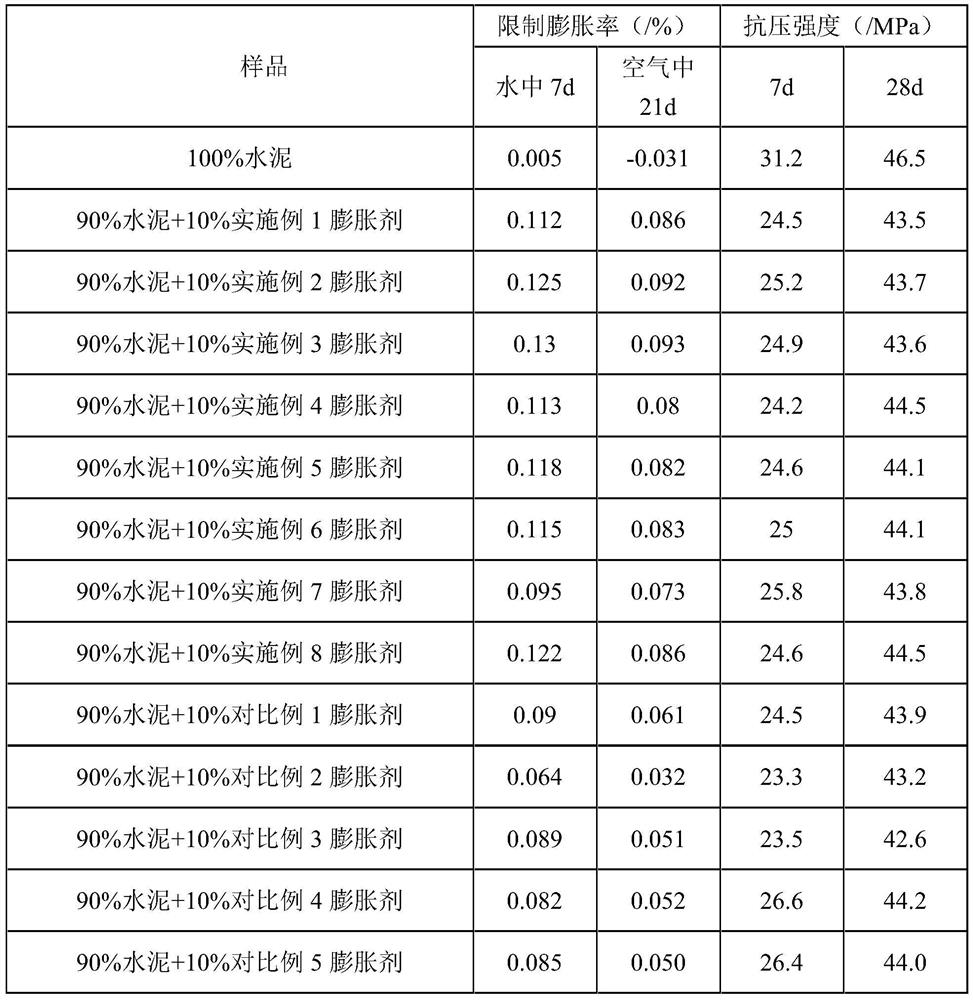

A technology for compensating shrinkage and calcium oxide, applied in the field of building materials, can solve the problems of not providing the influence of concrete setting time, reducing concrete slump and expansion, affecting concrete setting time, etc., to reduce the hydration reaction rate, condensation The effect of small time influence and simple and practical preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Put 1% sodium sulfate and 99% calcium oxide expansion agent together in a ball mill for 30 minutes, and then pass through an 80 μm square hole sieve to obtain a modified calcium oxide expansion agent.

Embodiment 2

[0038] Put 5% sodium sulfate and 95% calcium oxide expansion agent into a ball mill to mill for 30 minutes, and then pass through an 80 μm square hole sieve to obtain a modified calcium oxide expansion agent.

Embodiment 3

[0040] Put 10% sodium sulfate and 90% calcium oxide expansion agent in a ball mill together for 30 minutes by mass, and then pass through an 80 μm square hole sieve to obtain a modified calcium oxide expansion agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com