Surface-tinned winding strip slitting and winding device and process method

A winding device and tinning technology, which is applied in the direction of winding strips, transportation and packaging, and sending objects, can solve the problems of low production capacity, surface scratches, and high cost of tinning on the surface, so as to achieve a good product surface and increase Production capacity and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to better understand the present invention, the present invention will be further elaborated below in conjunction with specific examples, but the examples do not constitute a limitation to the protection scope of the claims of the present invention. Other obtained embodiments all belong to the protection scope of the present invention.

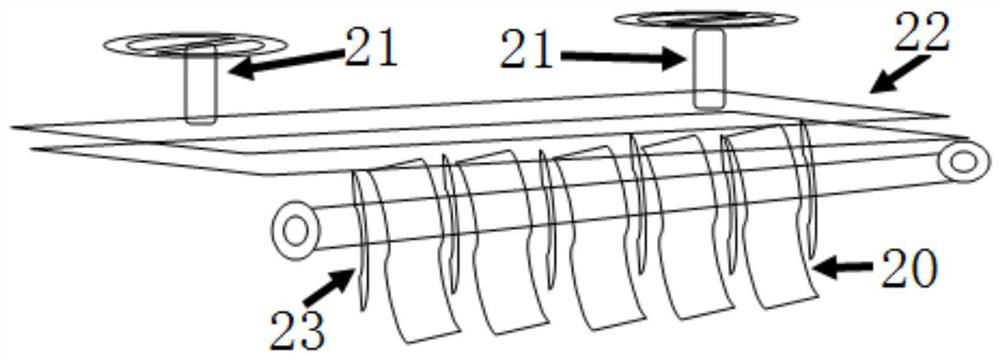

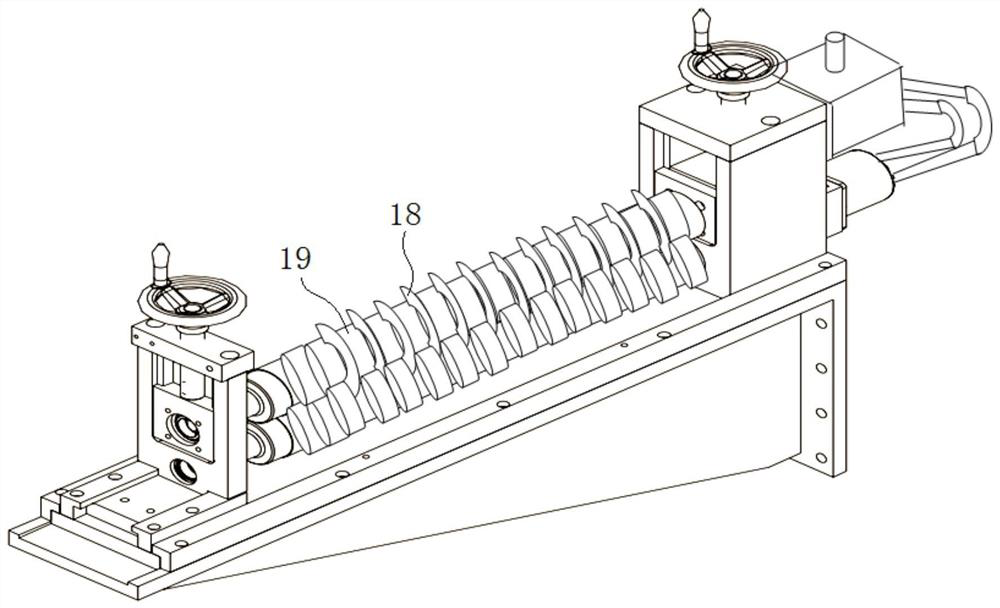

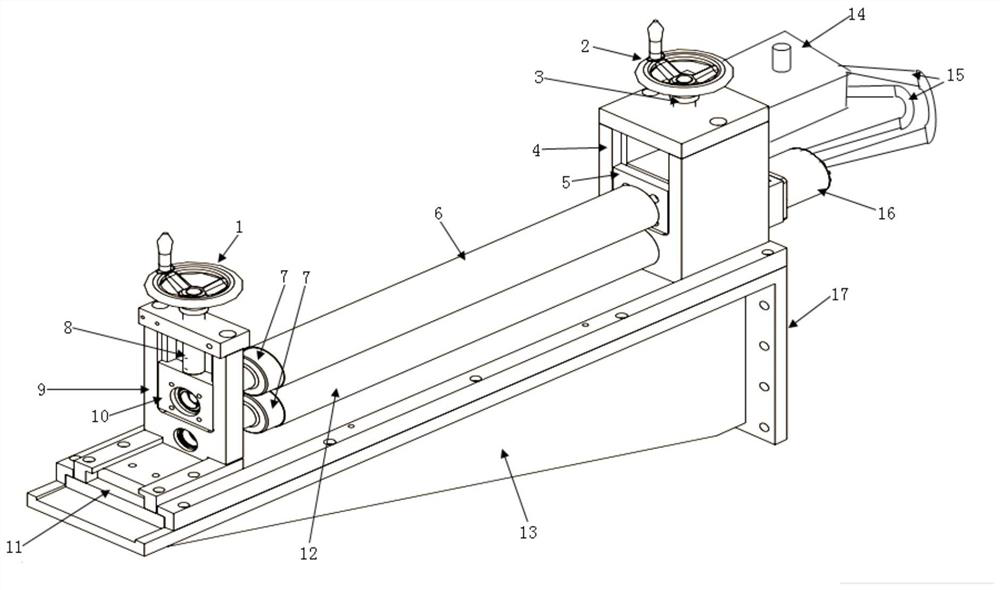

[0029] A kind of surface tinned strip strip rewinding device, such as Figure 4 As shown, it includes a first main shaft 6, a second main shaft 12, a partition 18 and rubber sleeves 19, the first main shaft 6 and the second main shaft 12 are arranged on two balance pillars 9 in parallel, and several of the rubber sleeves 19 is inserted into the first main shaft 6 and the second main shaft 12, and a partition 18 is arranged on the first main shaft 6, and the partition 18 fixes the rubber sleeve 19. When installing, make the rubber sleeve 19 according to the width of the tinned coil, insert the rubber sleeve 19 into the first ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com