Method for spooling a thread on a textile machine which produces crosswound bobbins, and textile machine which produces crosswound bobbins

A technology for cross-winding bobbins and textile machines, which is used in the field of spinning yarn on textile machines for producing cross-winding bobbins and textile machines for producing cross-winding bobbins, and can solve problems such as yarn emptying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

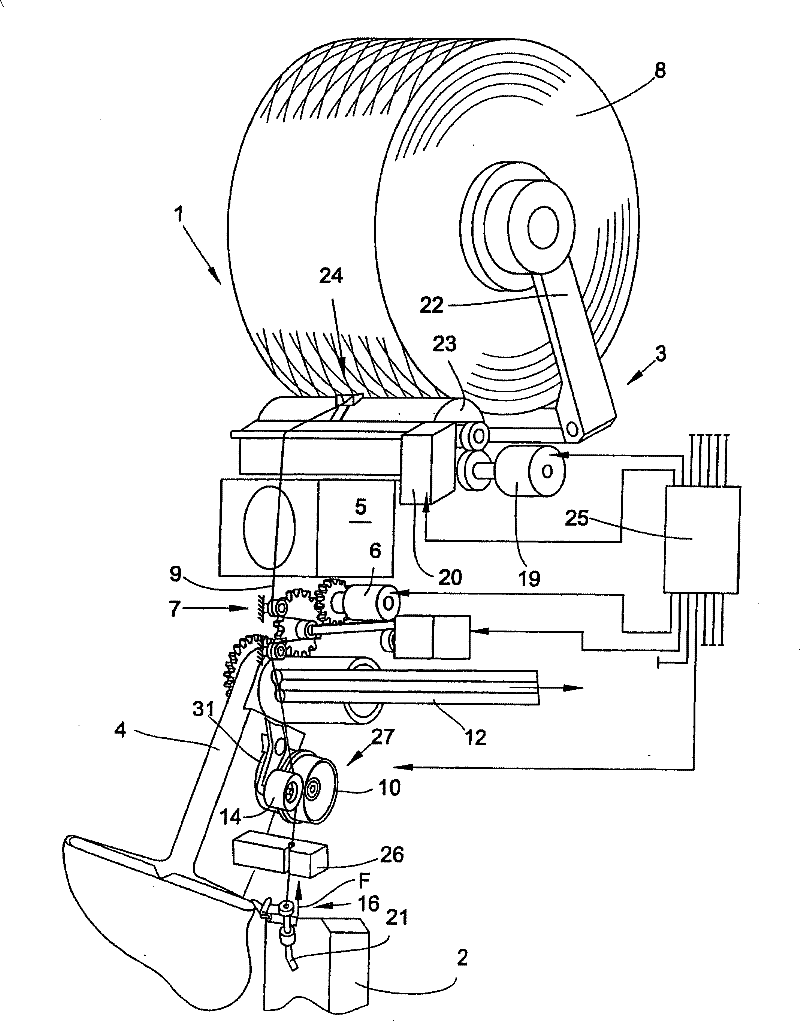

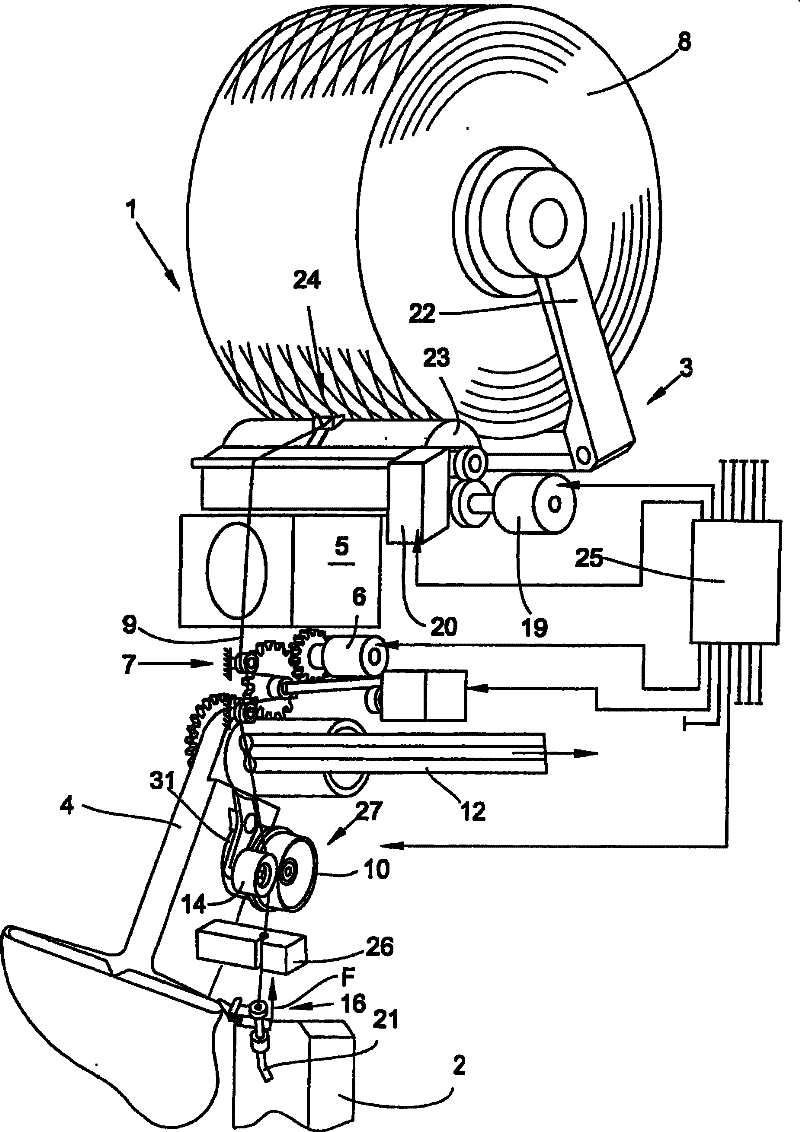

[0016] figure 1 Shows a perspective view of a workstation 1 of an open-end rotor textile machine, which is only shown schematically because it is known, with an open-end spinning mechanism 2 and a winding mechanism 3 for producing a yarn 9 , the winding mechanism is connected downstream in the yarn running direction F. Yarn 9 is wound onto said winding mechanism 3 to form a cross-wound bobbin 8 .

[0017] As shown, the yarn 9 produced in the open-end spinning mechanism 2 is drawn out from the open-end spinning mechanism 2 by means of a yarn drafting device 27 which has a yarn draft driven by a single motor. A pulling roll 10, and a pressure roll 14, which may be positioned on the yarn pulling roll 10 and driven by frictional engagement.

[0018] In addition if figure 1 As shown, the yarn 9 leaves the free-end spinning mechanism 2 through a so-called yarn drafting tube 21, in the region of which a pivotally mounted auxiliary joint member 16 is also provided, after the yarn h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com