Reel of magnetic tape cartridge

A tape-reel and tape technology, used in magazine/cassette storage, magazine/cassette manufacturing equipment, and recording carrier guidance, etc., can solve the problem of reduced dimensional accuracy of molded products, inability to clamp, and poor resin filling and other problems, to achieve the effect of improving the forming accuracy, increasing the winding tension, and improving the bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

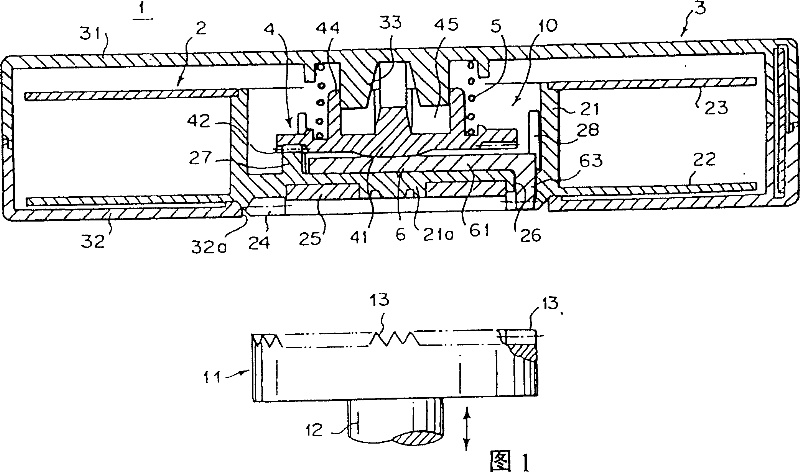

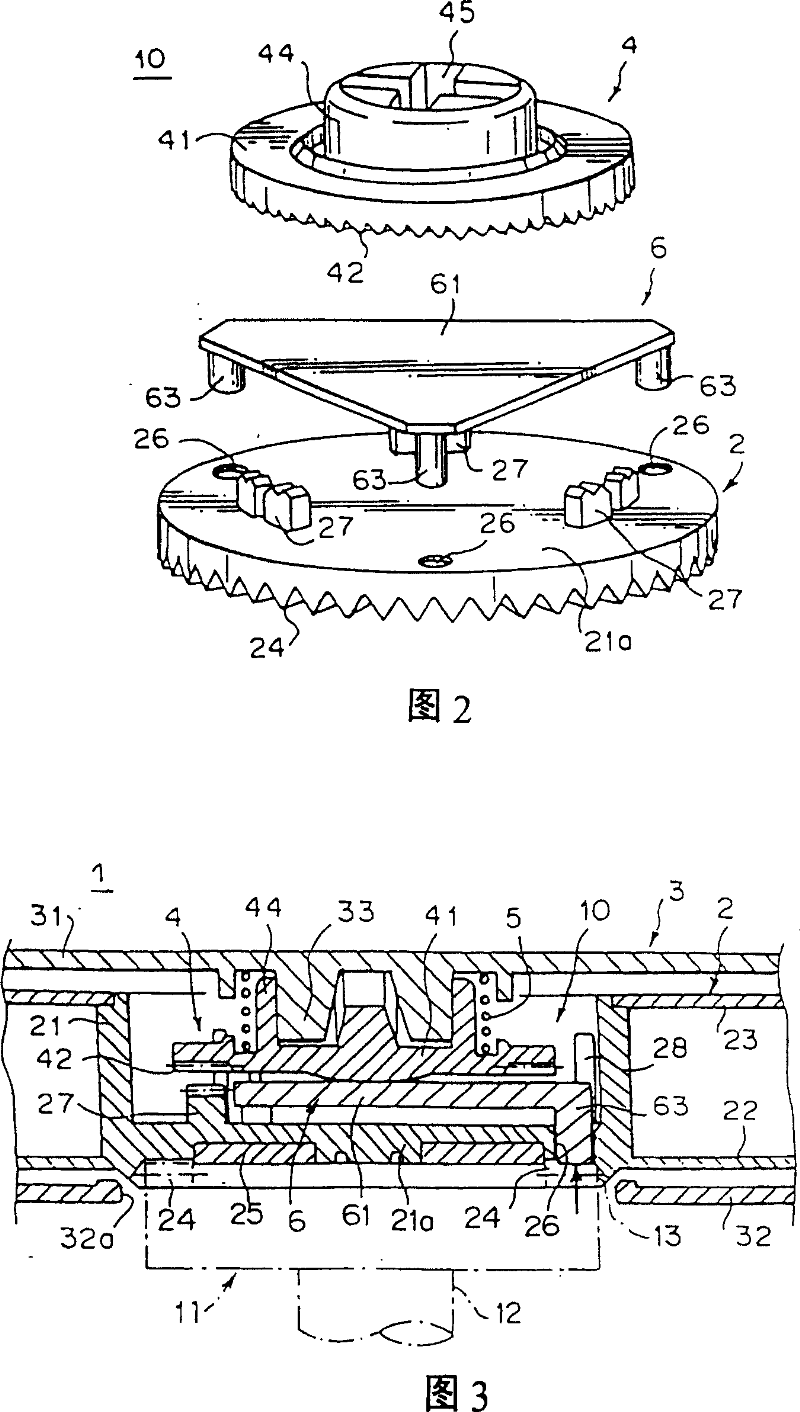

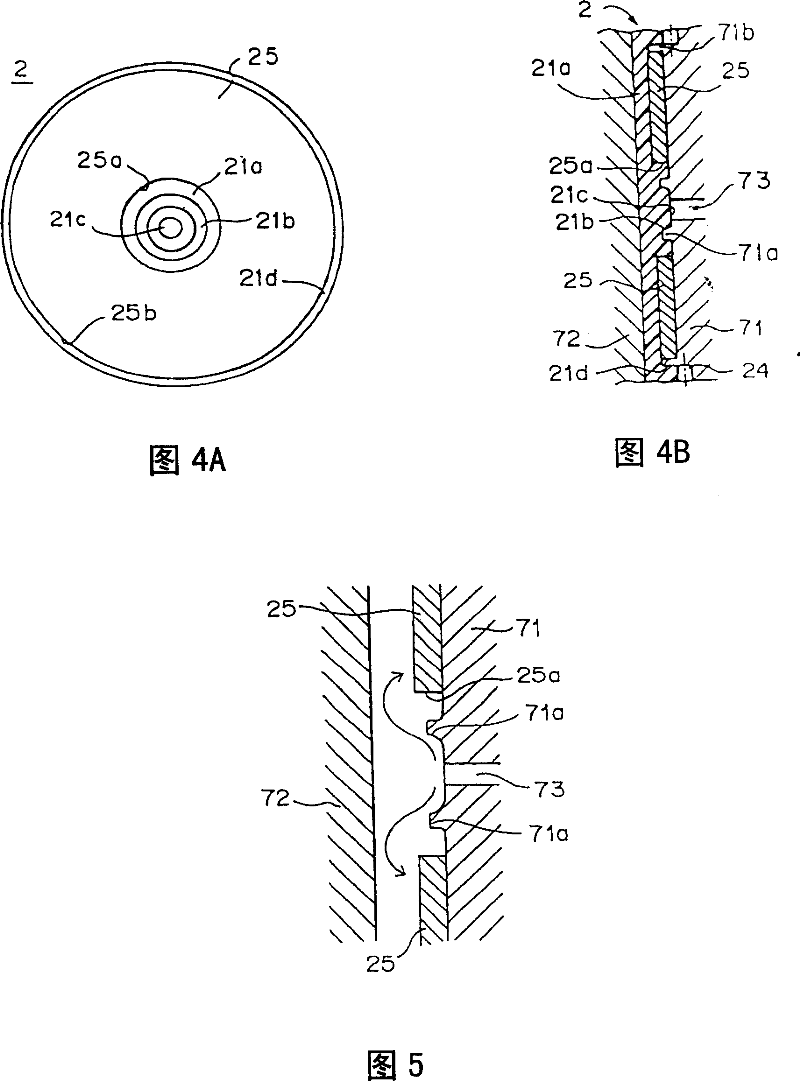

[0050] Embodiment 1 of the present invention for achieving the first object will be described in detail below with reference to the drawings. Fig. 1 is the cross-sectional front view of the tape cassette with the tape control reel of Embodiment 1 of the present invention in the non-use state; Fig. 2 is an exploded perspective view showing the main parts of the tape cassette in Fig. 1; Fig. 3 is a view showing that the tape cassette in Fig. 1 is in use Sectional view of the main parts in the state.

[0051] The structure of the tape cassette 1 is: a tape (not shown) is wound on a single tape control reel 2, and a tape cassette case in which an upper case 31 and a lower case 32 having an opening 32a in the center are connected and fixed by means of small screws or the like. 3, the tape control reel 2 is accommodated and enabled to rotate.

[0052] The tape control reel 2 includes: a bottomed cylindrical tape control reel center 21 on which a magnetic tape is wound on the outer ...

Embodiment 2

[0068] Embodiment 2 and Embodiment 3 of the present invention for achieving the second object will be described in detail below with reference to the drawings.

[0069] Fig. 6 is the sectional view of the tape control reel of the magnetic tape cassette according to Embodiment 2 of the present invention;

[0070] Fig. 7 is an enlarged view of main parts of Fig. 6 .

[0071] The tape control reel 101 is a cylindrical hub 103 on which a magnetic tape is wound on an outer peripheral surface 103a by using synthetic resin, and a disc-like extension extending radially from the outer circumference of the hub 103 side end (lower in the figure). The formed flange portion 104 is integrally formed, and a disc-shaped flange 105 molded separately from synthetic resin is fixed to the other end portion of the hub 103 with an adhesive.

[0072] The disk-shaped inner wall 111 is connected to the inner peripheral side of the hub 103, and the outer surface of the inner wall 111 is annularly prov...

Embodiment 3

[0088] And, in the present embodiment 3, also can according to need, the bonding part between the recessed part end surface 109a of the hub 103 and the inner peripheral side flange face 105a of the flange 105 and / or the recessed part peripheral surface of the hub 103 At least one of the two bonding surfaces of the bonding portion between the bonding portion 109b and the inner peripheral end surface 105b of the flange 105 is roughened, thereby improving the bonding strength with the adhesive.

[0089] Same as the previous example, according to the present embodiment 3, by using an adhesive to combine the hub 103 and the flange 105, the flange 105 can not be deformed, and the whole circumference can be evenly bonded, and the flange 105 The rotation vibration is small, and the variation in the width direction is also relatively small when the tape is running, so it can meet the requirements of high density.

[0090] Moreover, by bonding the hub 103 and the flange 105 with two ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com