Heterogeneous core-shell g-C3N5@MnO2 complex and preparation method thereof

A technology of g-c3n5, complex, applied in chemical instruments and methods, chemical/physical process, physical/chemical process catalyst, etc., can solve the problems of high cost, complex synthesis process, long time-consuming, etc., and achieve low cost , excellent photocatalytic performance, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

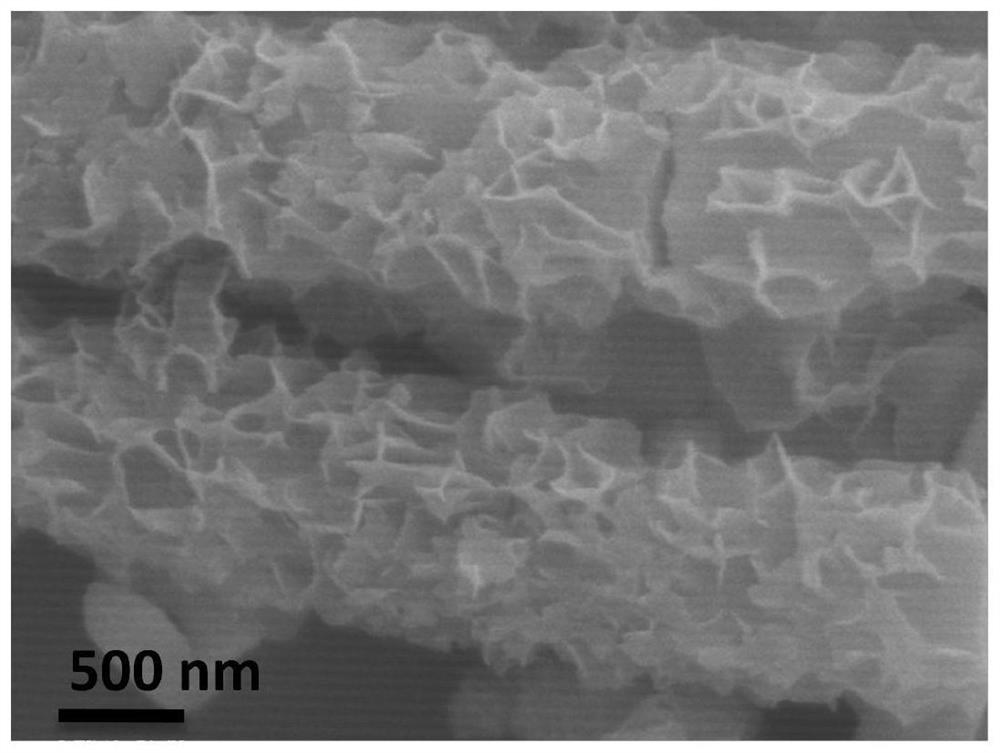

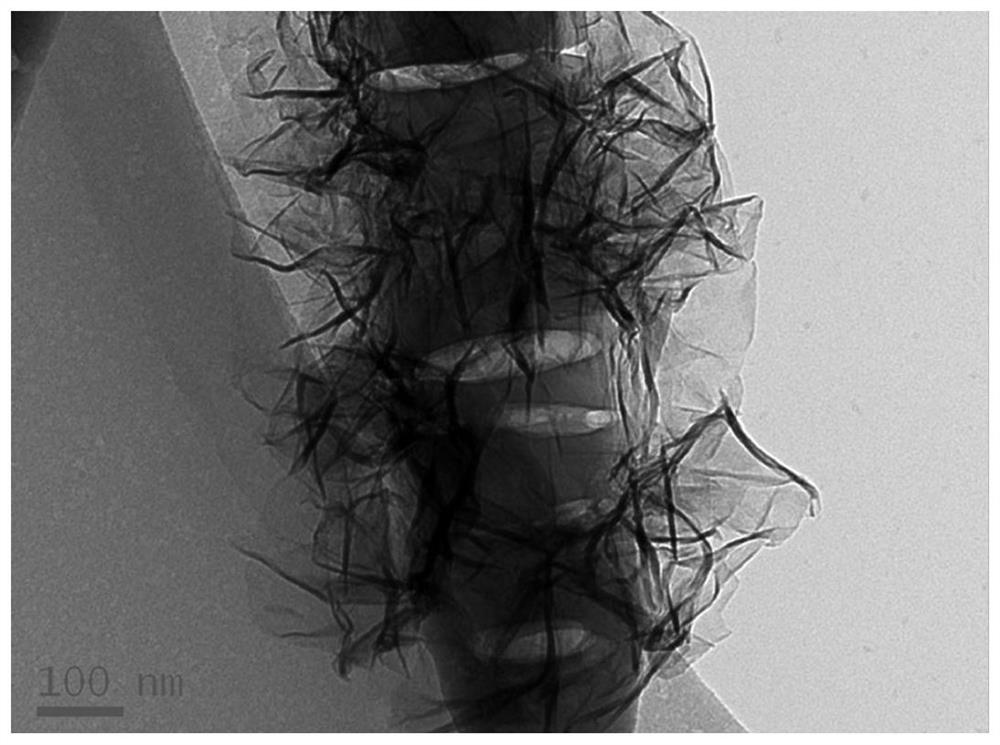

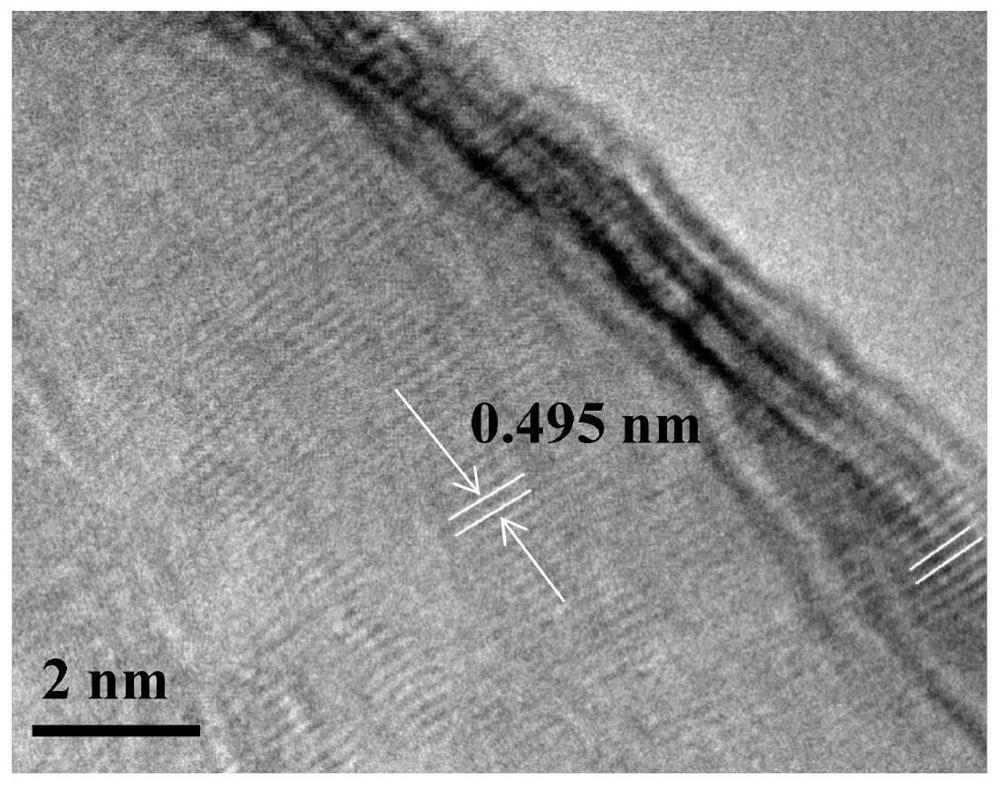

[0048] A heterogeneous core-shell g-C 3 N 5 @MnO 2 Complex, in stick form g-C 3 N 5 For the kernel, in rod g-C 3 N 5 The surface is compounded with MnO 2 Nano sheet, its preparation method, comprises the steps:

[0049] (1) Preparation of rod-shaped g-C 3 N 5 , specifically obtained by the following preparation method: 3-amino-1,2,4-triazole (1.5g) was added to KBr solution (10.0g KBr in 30mL H 2 O), after the solution is mixed evenly, it is heated at 80°C to evaporate the water to dryness to obtain a solid mixture of 3-amino-1,2,4-triazole and KBr, and at the same time, the solid mixture is dried to obtain a dry powder; then the dry powder was calcined at a temperature of 500°C for 3h in an air atmosphere (the heating rate was 5-10°C·min -1 ), after cooling, a tan product was obtained; after the tan product was washed with water, suction filtered, and dried, a rod-shaped g-C 3 N 5 ; Meanwhile, rod-shaped g-C was prepared by using the above 3 N 5 The method of us...

Embodiment 2

[0060] A heterogeneous core-shell g-C 3 N 5 @MnO 2 Complex, in stick form g-C 3 N 5 For the kernel, in rod g-C 3 N 5 The surface is compounded with MnO 2 Nano sheet, its preparation method, comprises the steps:

[0061] (1) Preparation of rod-shaped g-C 3 N 5 , specifically obtained by the following preparation method: 3-amino-1,2,4-triazole (1.5g) was added to KBr solution (10.0g KBr in 30mL H 2 O), after the solution is mixed evenly, it is heated at 80°C to evaporate the water to dryness to obtain a solid mixture of 3-amino-1,2,4-triazole and KBr, and at the same time, the solid mixture is dried to obtain a dry powder; then the dry powder was calcined at a temperature of 500°C for 3h in an air atmosphere (the heating rate was 5-10°C·min -1 ), after cooling, a tan product was obtained; after the tan product was washed with water, suction filtered, and dried, a rod-shaped g-C 3 N 5 ; Meanwhile, rod-shaped g-C was prepared by using the above 3 N 5 The method of us...

Embodiment 3

[0067] A heterogeneous core-shell g-C 3 N 5 @MnO 2 Complex, in stick form g-C 3 N 5 For the kernel, in rod g-C 3 N 5 The surface is compounded with MnO 2 Nano sheet, its preparation method, comprises the steps:

[0068] (1) Preparation of rod-shaped g-C 3 N 5 , specifically obtained by the following preparation method: 3-amino-1,2,4-triazole (1.5g) was added to KBr solution (10.0g KBr in 30mL H 2 O), after the solution is mixed evenly, it is heated at 80°C to evaporate the water to dryness to obtain a solid mixture of 3-amino-1,2,4-triazole and KBr, and at the same time, the solid mixture is dried to obtain a dry powder; then the dry powder was calcined at a temperature of 500°C for 3h in an air atmosphere (the heating rate was 5-10°C·min -1 ), after cooling, a tan product was obtained; after the tan product was washed with water, suction filtered, and dried, a rod-shaped g-C 3 N 5 ; Meanwhile, rod-shaped g-C was prepared by using the above 3 N 5 The method of us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com