Concrete-filled steel tube column top and sandwich concrete composite plate joint and construction method

A steel tube concrete column and concrete technology, which is applied in the direction of construction, building structure, and building material processing, can solve the problems of bulky concrete floors, high cost of steel structures, and low strength, so as to improve integrity, reduce structural weight, The effect of taking into account both construction efficiency and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

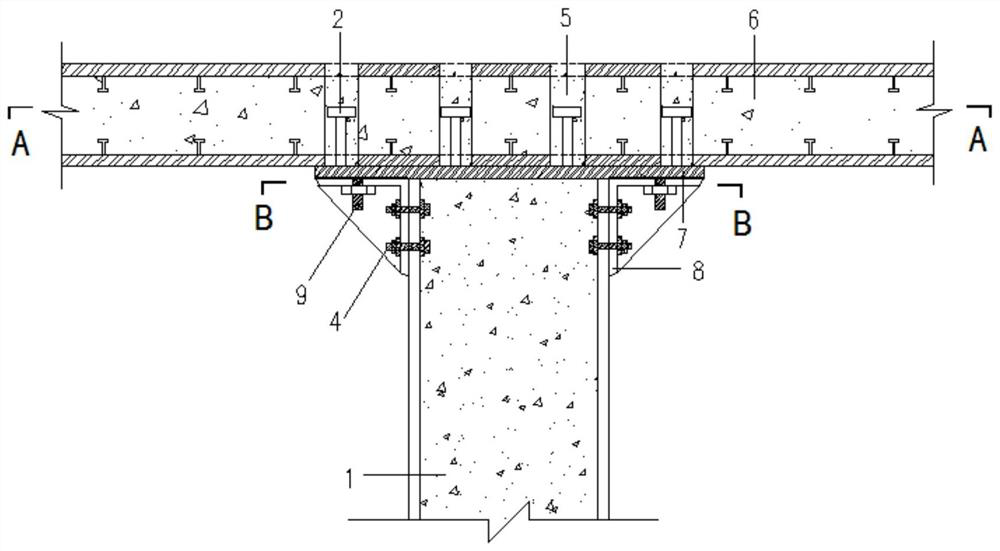

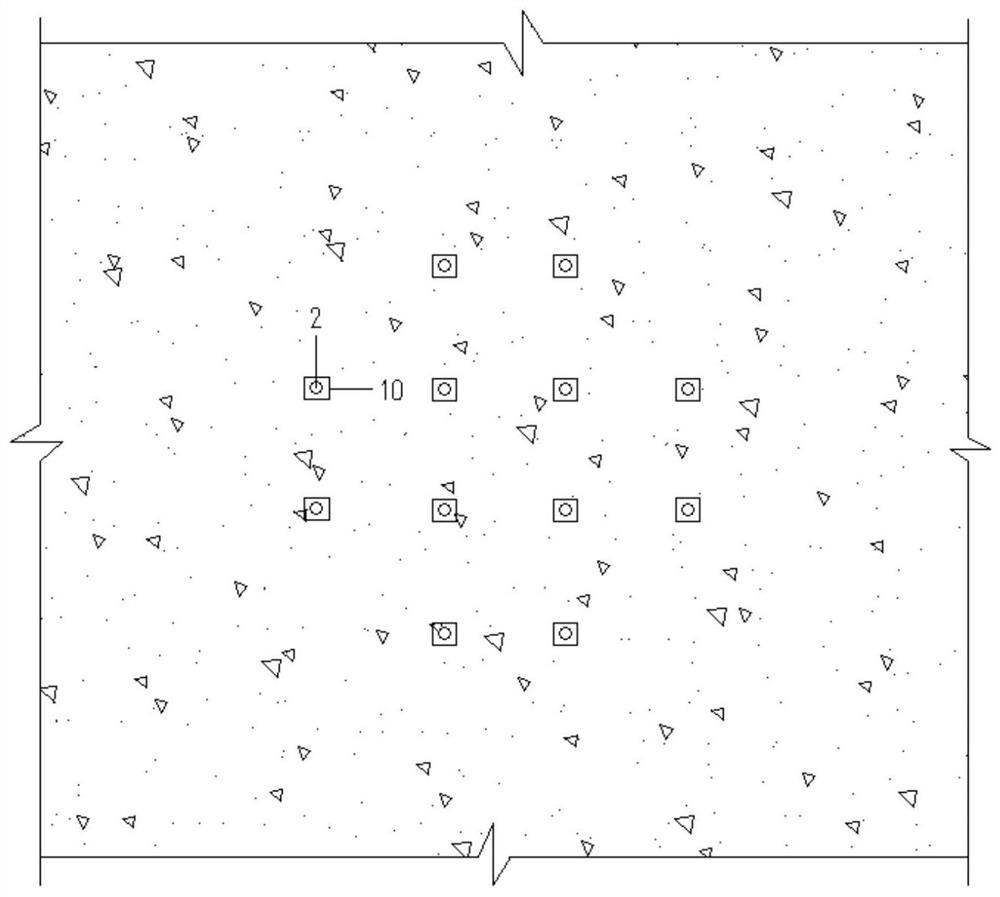

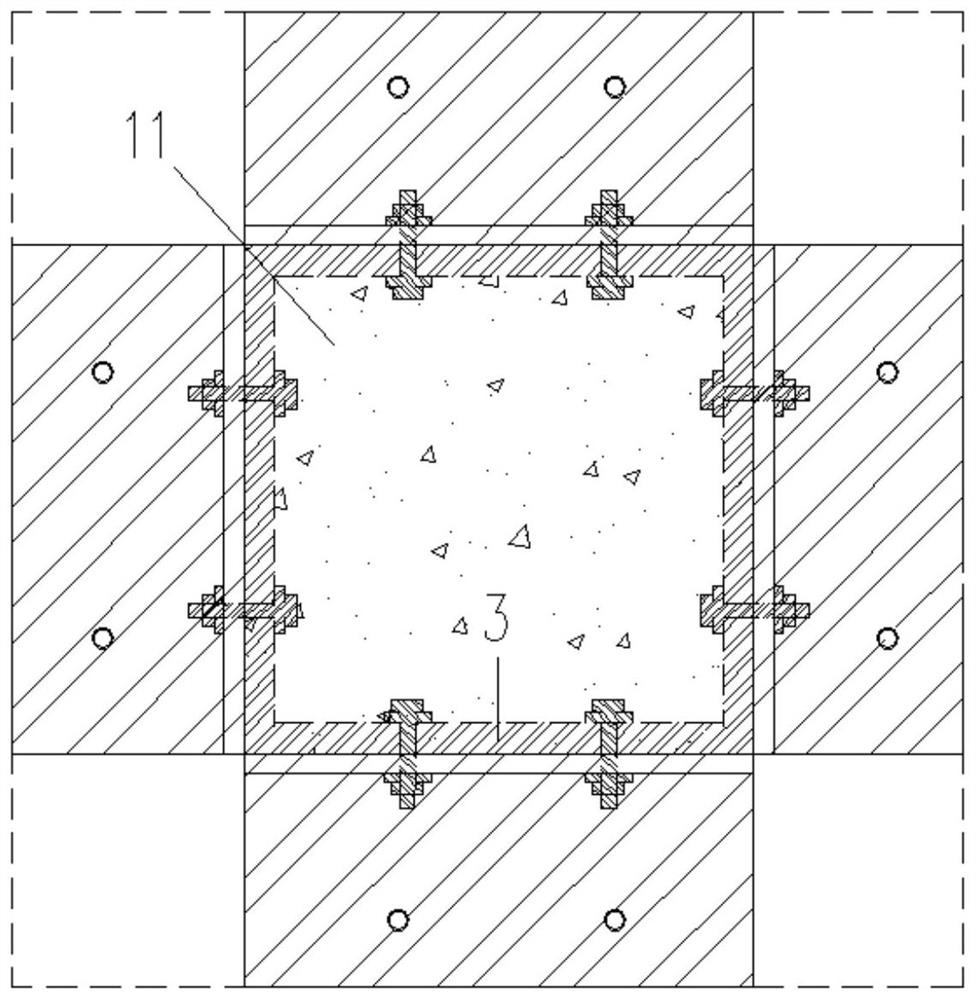

[0044] Such as Figure 1~5 As shown, a joint between the top of a steel tube concrete column and a sandwich concrete composite plate is connected by a steel plate and a stud, including a steel tube concrete column 1, a sandwich concrete composite plate 6, a supporting angle steel 8, a connecting steel plate 7, and embedded bolts 4, Pre-welded screw 9 and stud 2; the connecting steel plate 7 is horizontally welded and fixed on the top of the steel pipe concrete column 1; the supporting angle steel 8 is located between the connecting steel plate 7 and the sandwich concrete composite plate 6, and the vertical legs of the supporting angle steel 8 The steel pipe concrete column 1 is fixedly connected with the embedded bolt 4, and the horizontal leg of the supporting angle steel 8 is fixedly connected with the connecting steel plate 7 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com