Recombinant bacillus subtilis for producing feruloyl esterase and application of recombinant bacillus subtilis

A technology of Bacillus subtilis and ferulic acid esterase, which is applied in the biological field and can solve the problems of restricting the industrialization process of ferulic acid and low yield of ferulic acid esterase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1: Construction of recombinant Bacillus subtilis

[0038] Specific steps are as follows:

[0039] With the genome of Bacillus pumilus (Bacillus pumilus) SK52.001 obtained in Example 1 as a template, with fae-F / fae-R as primers, the gene (SEQ ID NO. 1); The gene encoding ferulic acid esterase and the pMA5 plasmid are connected with the homologous recombinase Exnase II to obtain a connection product; the connection product is transformed into Escherichia coli DH5α competent cells; the transformed Escherichia coli DH5α competent cells Cell-coated LB solid medium (containing 100 μg·mL -1 Ampicillin), cultured upside down at 37°C for 24 hours; pick positive transformants, extract plasmids, and sequence them for verification. If the verification is correct, the recombinant plasmid PMA5-fae is obtained; transform the obtained recombinant plasmid PMA5-fae into Bacillus subtilis WB800 to obtain the transformation product ; Spread the transformation product on LB sol...

Embodiment 2

[0043] Embodiment 2: the production of ferulic acid esterase

[0044] Specific steps are as follows:

[0045] The transformants of the recombinant Bacillus subtilis WB800 / PMA5-fae obtained in Example 1 were placed in LB solid medium (containing 100 μg·mL -1 Kanamycin), and cultured upside down in a 30°C incubator for 12 hours to obtain a single colony; pick a single colony and inoculate it into LB liquid medium (containing 100 μg·mL -1 Kanamycin) was cultivated at 37°C and 200r / min for 12h to obtain a seed liquid; the seed liquid was transferred to the SuperRich medium at an inoculum size of 3% (v / v), and cultivated at 37°C and 200r / min 60h, to obtain the fermentation broth.

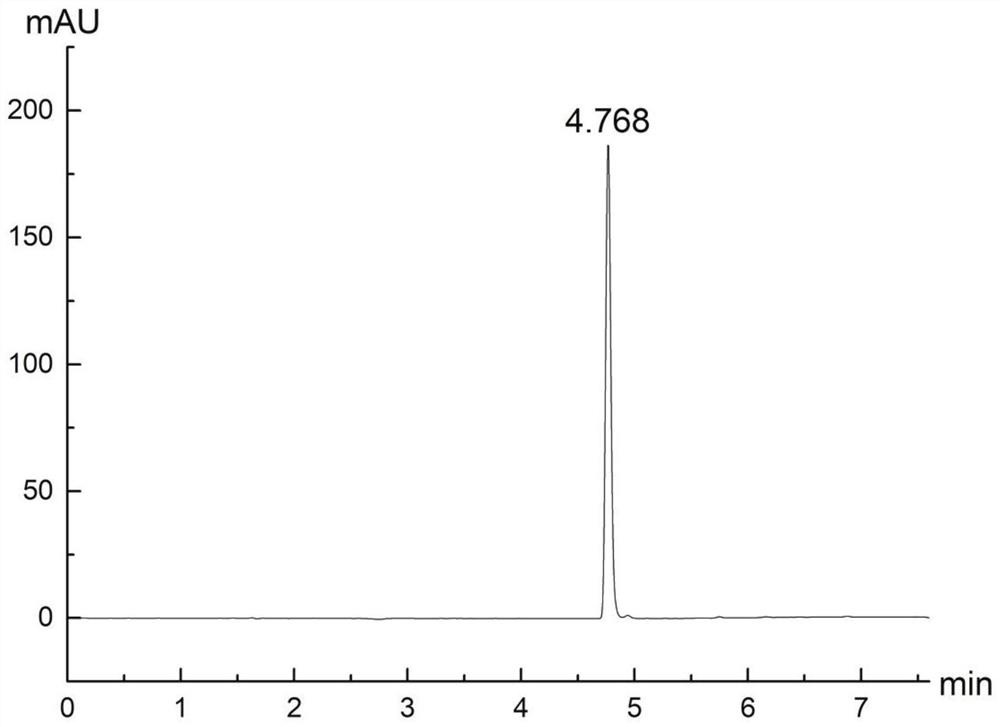

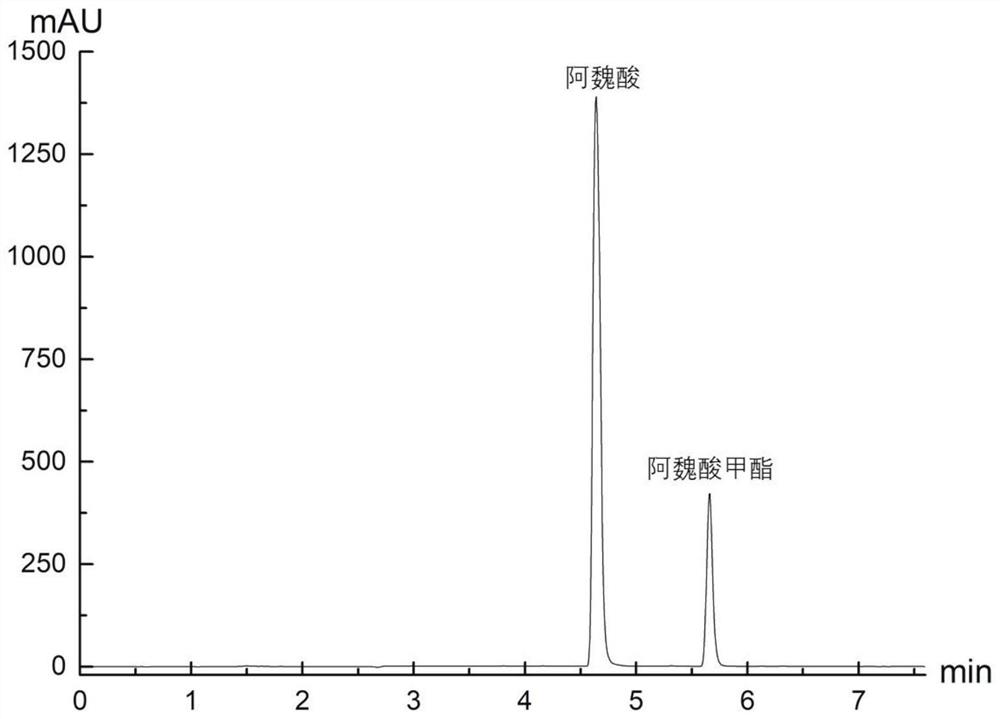

[0046] During the fermentation process, the fermentation broth was sampled at regular intervals, with a sampling volume of 1 mL; the fermentation broth was centrifuged at 4°C and 10,000 rpm for 15 minutes to obtain the fermentation supernatant and sediment; 1 mL of lysate was added to the sediment to r...

Embodiment 3

[0059] Embodiment 3: the production of ferulic acid esterase

[0060] Specific steps are as follows:

[0061] Taking Bacillus subtilis WB800 as a contrast, the transformants of the recombinant Bacillus subtilis WB800 / PMA5-fae obtained in Example 1 were grown in LB solid medium (containing 100 μg·mL -1 Kanamycin), and cultured upside down in a 30°C incubator for 12 hours to obtain a single colony; pick a single colony and inoculate it into LB liquid medium (containing 100 μg·mL -1 Kanamycin) was cultivated at 37°C and 200r / min for 12h to obtain a seed liquid; the seed liquid was transferred to the SuperRich medium at an inoculum size of 3% (v / v), and cultivated at 37°C and 200r / min 14h to obtain the fermented liquid.

[0062] After the fermentation, take 5 mL of fermentation broth, centrifuge the fermentation broth at 4°C and 8000 rpm for 15 minutes to obtain the fermentation supernatant and precipitate; add 5 mL of lysate to the precipitate to resuspend the bacteria to obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com