Alginate lyase producing strain and application thereof

A technology for alginate lyase and alginate production, applied in the field of strains producing alginate lyase, can solve the problems of single degradation site, restriction of development of alginate oligosaccharides, and low enzyme activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of above-mentioned alginate lyase preferably comprises the following steps:

[0035] (1) Strain activation: inoculate the above-mentioned Neiella sp.HB171785 on a solid medium and culture at 28-37°C for 24-48 hours to obtain an activated strain;

[0036] (2) Liquid culture: Scrape off a ring of bacteria from the purified plate, insert it into 30mL liquid seed medium, and culture it at 28-37°C and 120-200r / min for 12-15h to the logarithmic growth phase. make seed solution;

[0037] (3) Fermentation culture: the seed liquid is inoculated in the liquid fermentation medium according to the volume percentage of 2-10%, at 28-37 ° C, 150-200r / min shaking culture for 24-60h, the fermentation liquid is collected, 8000r / min min centrifuged for 10 min, and the supernatant was collected to obtain the alginate lyase crude enzyme solution.

[0038] In the preparation method of the alginate lyase:

[0039] The solid medium formula described in step (1) is: so...

Embodiment 1

[0045] Example 1 Isolation and screening of enzyme-producing strain HB171785 GDMCC No.61001

[0046] Sand samples were collected in Qishui Bay, Wenchang City, Hainan Province. Take 10g sample and dilute to 10 -3 ~10 -6 Suspension, draw 0.1mL of series suspension, spread on alginate lyase separation medium, place in 30°C incubator and incubate upside down for 2-5 days.

[0047] When the colonies grow out, according to the phenotypic characteristics of the colony shape, color, edge state, transparency, surface dry and wet state, etc., pick the colonies that grow well and have different shapes for streaking and purification.

[0048] The activity of alginate lyase was determined for the isolated strains, and the strain HB171785 with strong enzyme activity was screened out.

[0049] The specific process is as follows:

[0050] Pick the strain to be tested and spot it on the medium for detecting alginate lyase activity, and culture it at 30°C for 2-3 days. After obvious coloni...

Embodiment 2

[0055] Example 2 Identification of bacterial strain HB171785 GDMCC No.61001

[0056] Strain HB171785 GDMCC No.61001 grows well on 2216E agar medium. After 2 days of culture, clear colonies can be seen. The colonies are round, cream to grayish yellow, with neat edges, smooth and moist surface, and slightly raised center with a diameter of 2-3mm. Observed under the electron microscope, the cells are long rod-shaped, 2.2-4.5 μm long, 0.4-0.7 μm wide, with 1-2 polar or lateral flagella. Gram stain was negative.

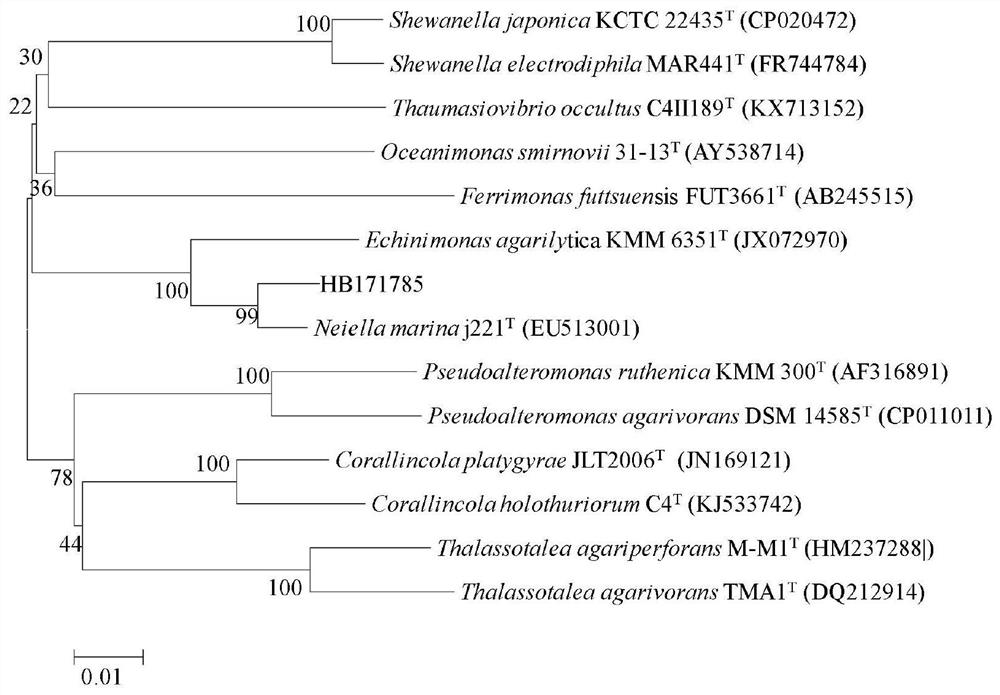

[0057] The 16S rDNA sequence 1459bp of HB171785 was obtained by PCR amplification and sequencing, and its nucleotide sequence is shown in SEQ ID No.1. Comparing the sequence with the sequence in the EzBioCloud database, it was found that strain HB171785 and Neiellamarina J221 T The homology is the highest (98.2%). Select related strains with high homology, and use the software MEGA7.0 to construct a phylogenetic tree using the Neighbor-joining method ( figure 2 ), it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com