Cleaning solution and preparation method thereof

A technology of cleaning liquid and solution, which is applied in the direction of chemical instruments and methods, detergent compositions, non-surface active cleaning solvents, etc., can solve the problems of time-consuming and labor-intensive cleaning of irregular utensils, threats to the health of users, and poor cleaning effects, etc., to achieve Cleaning saves time and effort, improves health protection, and enhances the effect of cleaning ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

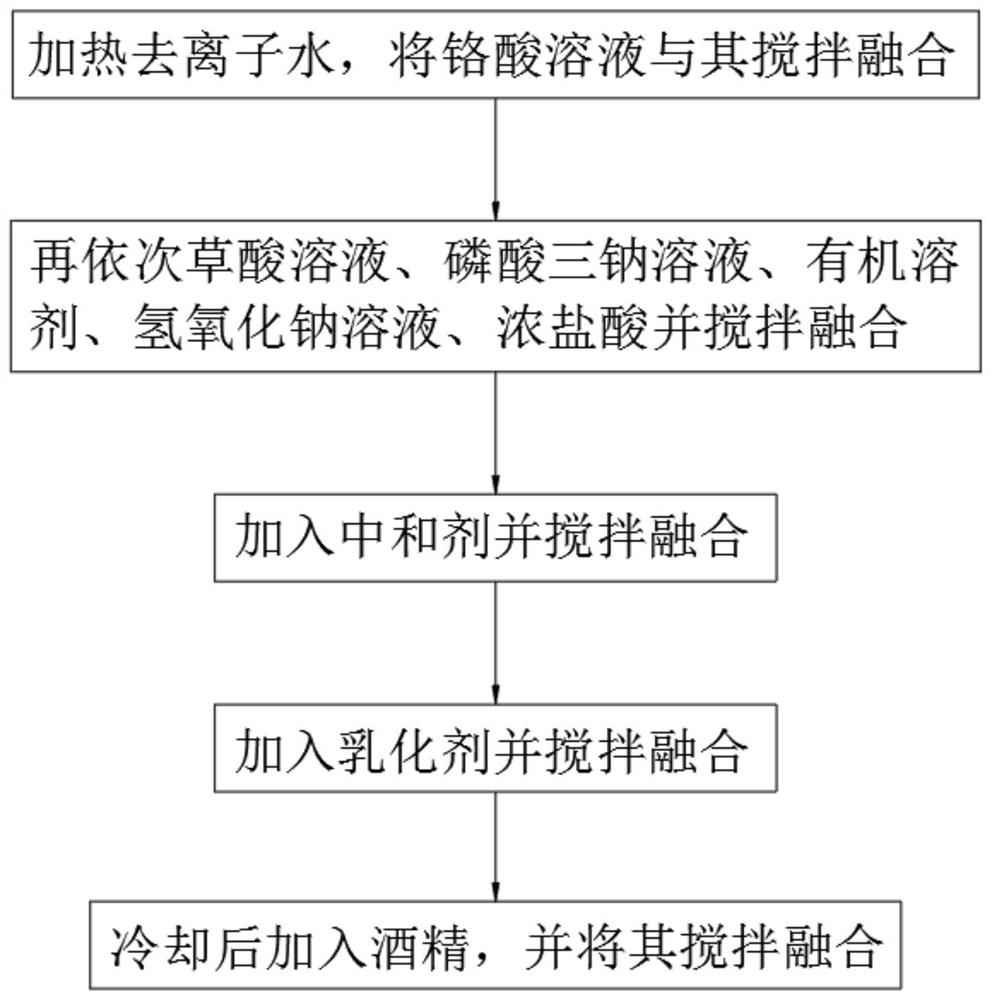

Image

Examples

Embodiment 1

[0023] A cleaning solution, calculated by weight components, wherein the raw materials include the following components: 25 parts of deionized water, 20 parts of alcohol, 5 parts of chromic acid solution, 4 parts of 5% oxalic acid solution, 8 parts of 10% trisodium phosphate solution , 6 parts of organic solvent, 12 parts of 10% sodium hydroxide solution, 6 parts of concentrated hydrochloric acid, 1 part of neutralizer and 1 part of emulsifier.

[0024] The raw materials for making chromic acid solution include concentrated sulfuric acid and sodium dichromate powder, and the ratio of concentrated sulfuric acid to sodium dichromate powder is 20:1.

[0025] The organic solvent is one of acetone, ether, ethanol, styrene, perchlorethylene, trichlorethylene, ethylene glycol ether and the like.

[0026] The neutralizing agent is one of sodium bicarbonate, sodium acetate, sodium pyrophosphate, diethanolamine, triethanolamine, glycine and the like.

[0027] Trisodium phosphate soluti...

Embodiment 2

[0039] A cleaning solution, calculated by weight components, wherein the raw materials include the following components: 38 parts of deionized water, 22 parts of alcohol, 15 parts of chromic acid solution, 14 parts of 5% oxalic acid solution, 15 parts of 10% trisodium phosphate solution , 10 parts of organic solvent, 17 parts of 10% sodium hydroxide solution, 9 parts of concentrated hydrochloric acid, 3 parts of neutralizing agent and 5 parts of emulsifier.

[0040] The raw materials for making chromic acid solution include concentrated sulfuric acid and sodium dichromate powder, and the ratio of concentrated sulfuric acid to sodium dichromate powder is 20:1.

[0041] The organic solvent is one of acetone, ether, ethanol, styrene, perchlorethylene, trichlorethylene, ethylene glycol ether and the like.

[0042] The neutralizing agent is one of sodium bicarbonate, sodium acetate, sodium pyrophosphate, diethanolamine, triethanolamine, glycine and the like.

[0043] Trisodium pho...

Embodiment 3

[0055] A cleaning solution, calculated by weight components, wherein the raw materials include the following components: 32 parts of deionized water, 25 parts of alcohol, 10 parts of chromic acid solution, 5 parts of 5% oxalic acid solution, 10 parts of 10% trisodium phosphate solution , 8 parts of organic solvent, 15 parts of 10% sodium hydroxide solution, 7 parts of concentrated hydrochloric acid, 2 parts of neutralizer and 3 parts of emulsifier.

[0056] The raw materials for making chromic acid solution include concentrated sulfuric acid and sodium dichromate powder, and the ratio of concentrated sulfuric acid to sodium dichromate powder is 20:1.

[0057] The organic solvent is one of acetone, ether, ethanol, styrene, perchlorethylene, trichlorethylene, ethylene glycol ether and the like.

[0058] The neutralizing agent is one of sodium bicarbonate, sodium acetate, sodium pyrophosphate, diethanolamine, triethanolamine, glycine and the like.

[0059] Trisodium phosphate so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com