Heat-transfer flame-retardant graphene heat-conducting plate and preparation method thereof

A heat conduction plate and graphene technology, applied in chemical instruments and methods, wood layered products, synthetic resin layered products, etc., can solve the problem of reducing heat conduction efficiency, poor heat transfer performance of support layers, and limitations of large-scale promotion and application, etc. problem, to achieve the effect of improving conduction efficiency, high security, wide application value and promotion space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

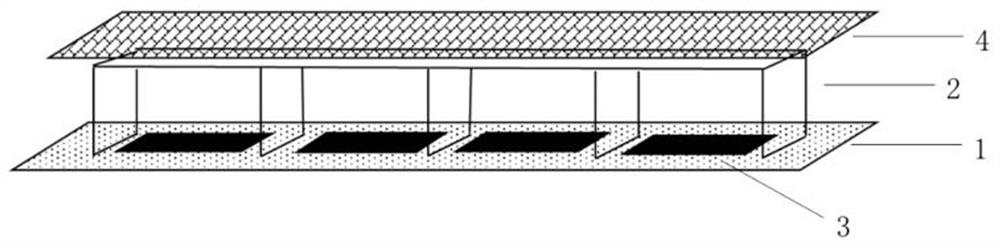

[0035] Such as figure 1 and Figure 5 As shown, a heat transfer and flame-retardant graphene heat conduction plate includes a bottom layer 1, a support layer 2 and a surface decoration layer 4, the support layer 2 is located between the bottom layer 1 and the surface decoration layer 4, and a heat generating Component 3 , the heating component 3 is tiled above the bottom layer 1 , and the surface decoration layer 4 is fixedly placed above the top of the support layer 2 .

[0036] The support layer 2 is a frame support layer containing several cavities. The frame support layer is made of fiber-reinforced resin composite material. The fiber in the fiber-reinforced resin composite material is glass fiber, and the resin is thermally conductive and flame-retardant unsaturated polyester. .

[0037] The bottom layer 1 is a rigid polyurethane foam layer, and the surface decoration layer 4 is a solid wood floor.

[0038] The heating component 3 is a graphene heating film layer.

[...

Embodiment 2

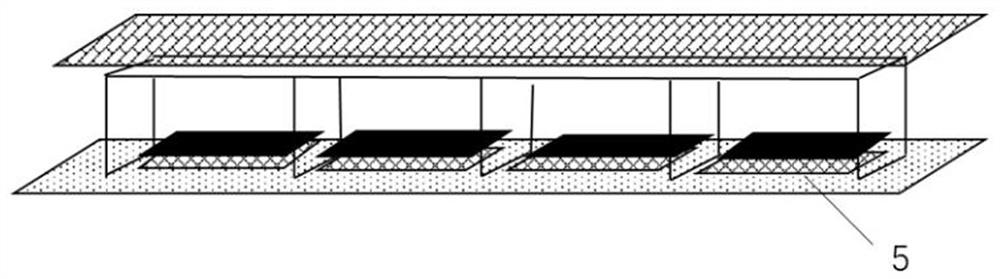

[0050] Such as figure 2 and Figure 5 As shown, a heat transfer and flame-retardant graphene heat conduction plate includes a bottom layer 1, a support layer 2 and a surface decoration layer 4, the support layer 2 is located between the bottom layer 1 and the surface decoration layer 4, and a heat generating Component 3, the heating component 3 is flatly laid on the bottom of the supporting layer 2, and a heat insulating layer 5 is arranged between the bottom layer 1 and the heating component 3, and the heat insulating layer 5 is a silica airgel felt layer.

[0051] The support layer 2 is a frame support layer containing several cavities, and the frame support layer is made of fiber-reinforced resin composite material, the fiber in the fiber-reinforced resin composite material is boron fiber, and the resin is epoxy resin.

[0052] The heating component 3 is a graphene heating film layer

[0053] The bottom layer 1 is a PVC foam board, and the surface decoration layer 4 is a...

Embodiment 3

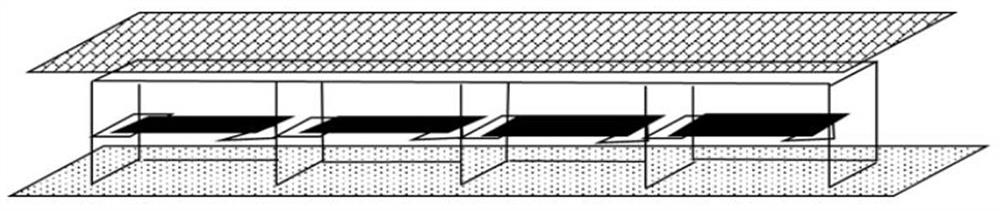

[0065] Such as image 3 and Figure 5 As shown, a heat transfer and flame-retardant graphene heat conduction plate includes a bottom layer 1, a support layer 2 and a surface decoration layer 4, the support layer 2 is located between the bottom layer 1 and the surface decoration layer 4, and a heat generating Component 3, wherein: the support layer 2 is a frame support layer including several cavities, and a support platform structure is included on the side inner wall of each cavity of the frame support layer, the heating component 3 is placed on the support platform structure, and the decorative layer Fixed placement above the top of support layer 2.

[0066] The support layer of the frame is made of fiber-reinforced resin composite material, the fiber in the fiber-reinforced resin composite material is aramid fiber, and the resin is unsaturated resin.

[0067] The bottom layer 1 is a rigid PVC foam board, and the surface decoration layer 4 is a reinforced composite floor. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com