A repair device for poor electrical contact inside a connector and a high-voltage cable

A technology of high-voltage cables and connectors, which is applied in the direction of two-part connection devices, parts and connections of connection devices, can solve problems such as potential safety hazards and economic losses, and achieve strong applicability, close contact, and good sealing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

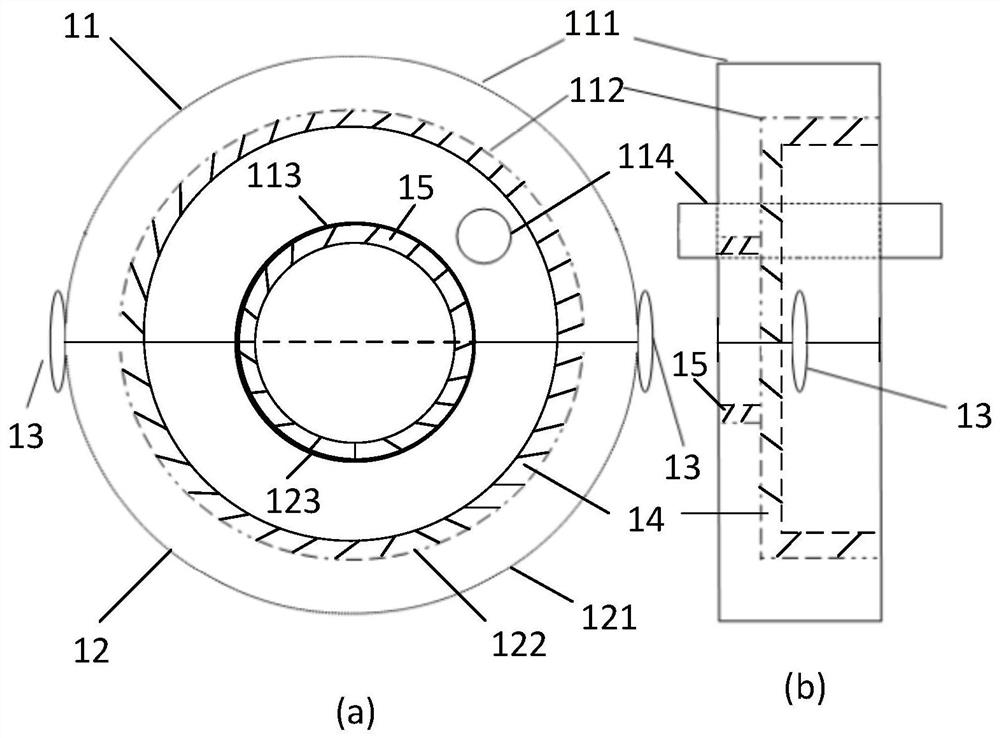

[0024] see figure 1 , is a structural schematic diagram of a connector provided in Embodiment 1 of the present invention, figure 1 (a) is a cross-sectional view of the connector, figure 1 (b) is a side view of the connector, and see figure 2 , is a schematic structural diagram of the cable provided in Embodiment 1 of the present invention. Wherein, the connector includes: a semicircular-arc-shaped first connecting body 11 and a second connecting body 12; the ports of the first connecting body 11 and the second connecting body 12 are provided with buckle components 13, The first connection body 11 and the second connection body 12 are connected through the buckle assembly 13;

[0025] Both the first connecting body 11 and the second connecting body 12 are provided with an outer shell, an inner shell and a semicircular inner hole; the outer shell is set on the outer side of the inner shell, and the semicircular inner hole runs through the outer shell With the inner shell, t...

Embodiment 2

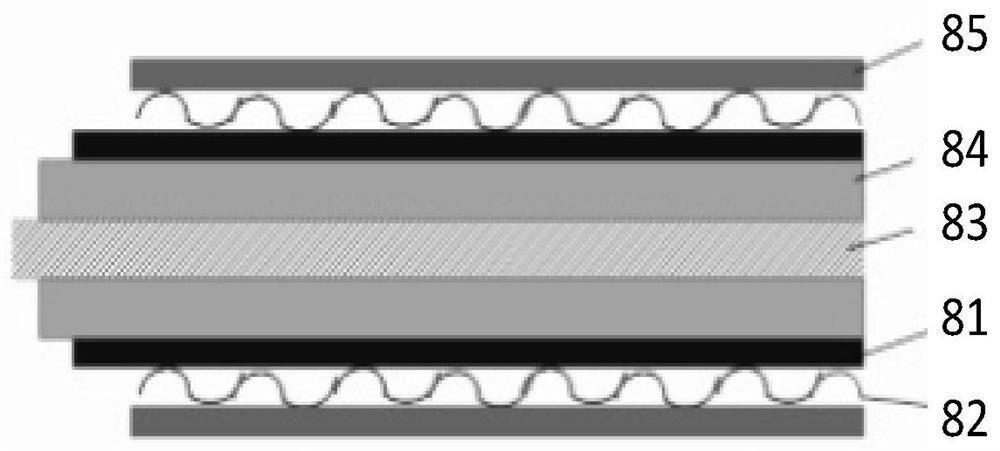

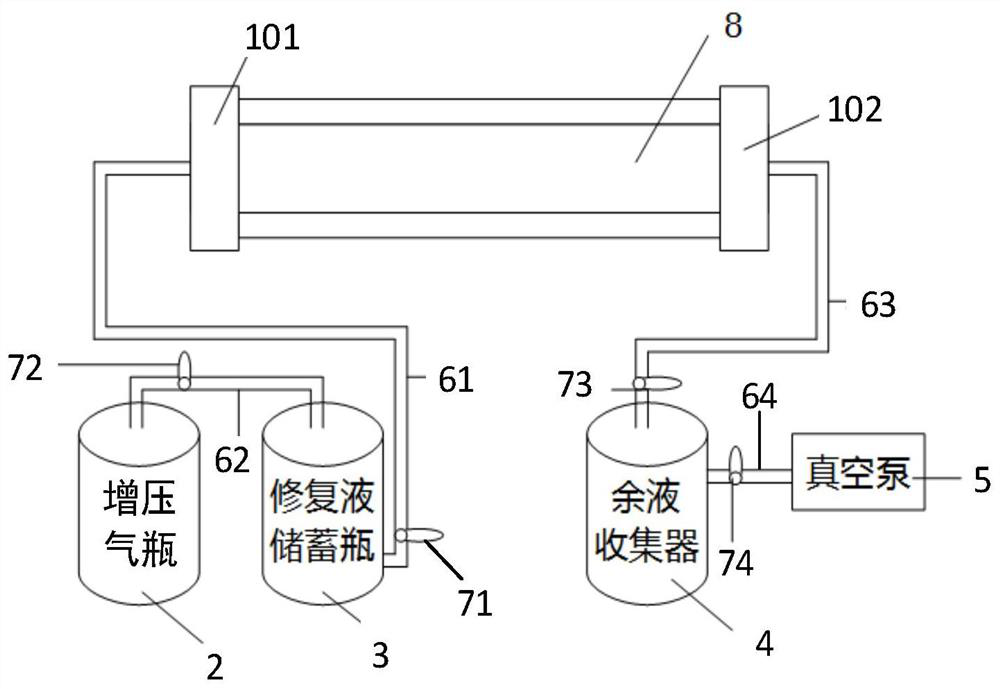

[0034] see image 3 , is a structural schematic diagram of a repairing device for poor electrical contact inside a high-voltage cable provided in Embodiment 2 of the present invention, including: a pressurized gas cylinder 2, a repairing liquid storage bottle 3, a repairing liquid, a first catheter 61, and a residual liquid Collector 4, vacuum pump 5 and the above-mentioned connector; the repair liquid is stored in the repair liquid storage bottle 3, and the pressurized gas cylinder 2 is connected to the repair liquid storage bottle 3; the repair liquid storage bottle 3 Connect the connector 101 sleeved on the first end of the cable 8 through the first catheter 61, so that the repair fluid is injected between the insulating shielding layer 81 and the aluminum sheath layer 82 of the cable 8 ; The connector 102 sleeved on the second end of the cable 8 is connected to the residual liquid collector 4 , and the residual liquid collector 4 is connected to the vacuum pump 5 .

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com