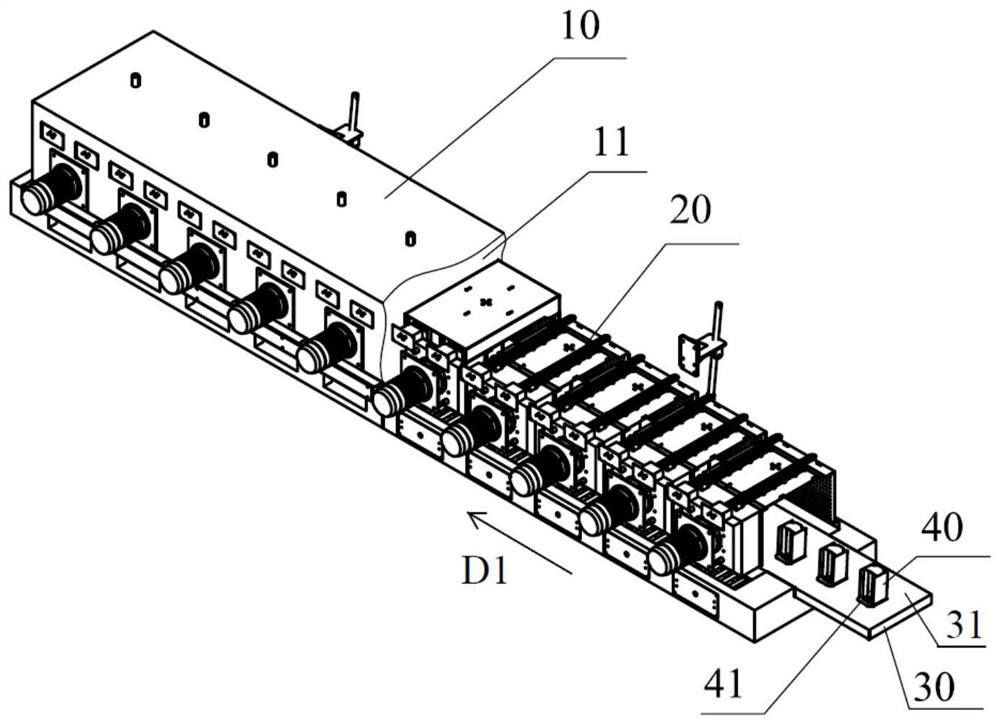

Curing device and drying equipment

A technology for curing devices and partitions, applied in lighting and heating equipment, drying, dryers, etc., can solve the problems of long curing time, large tiling area, and large area of heating furnaces, reducing the need for Small contact area, scratch prevention, and reduced footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific technical features in each embodiment described in the specific implementation modes can be combined in various ways if there is no contradiction. For example, different implementation modes can be formed by combining different specific technical features. Necessary repetition, various possible combinations of specific technical features in the present invention will not be further described.

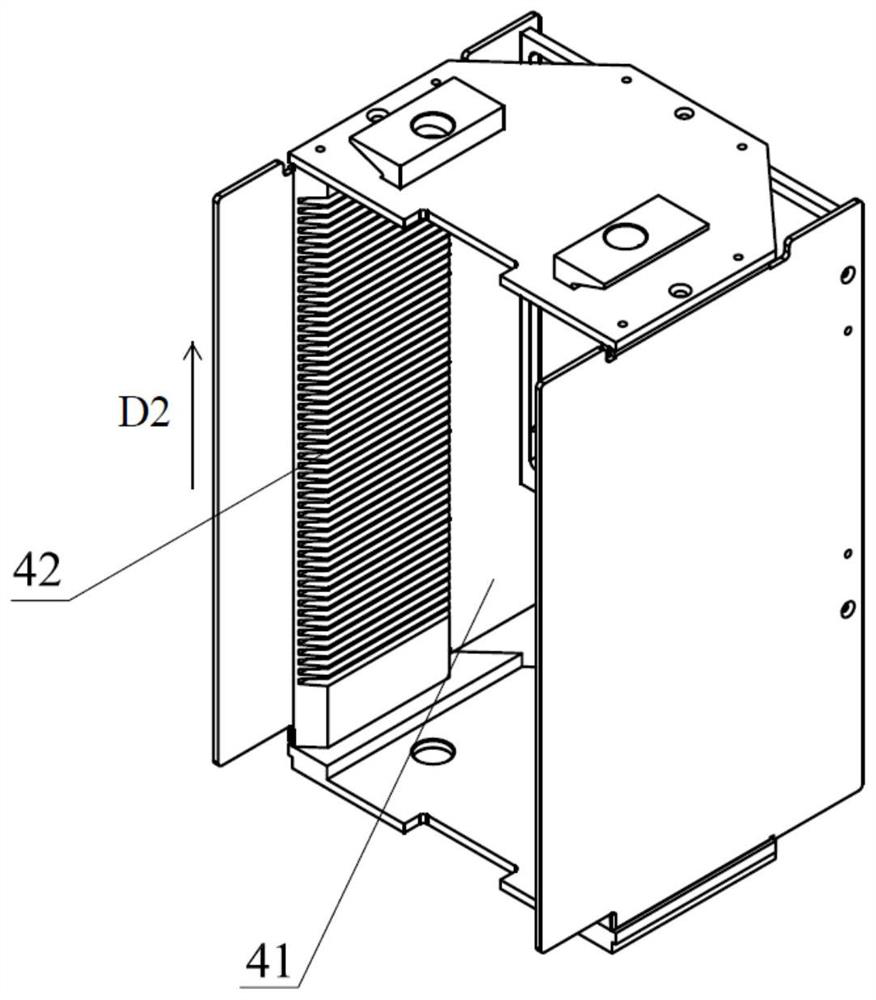

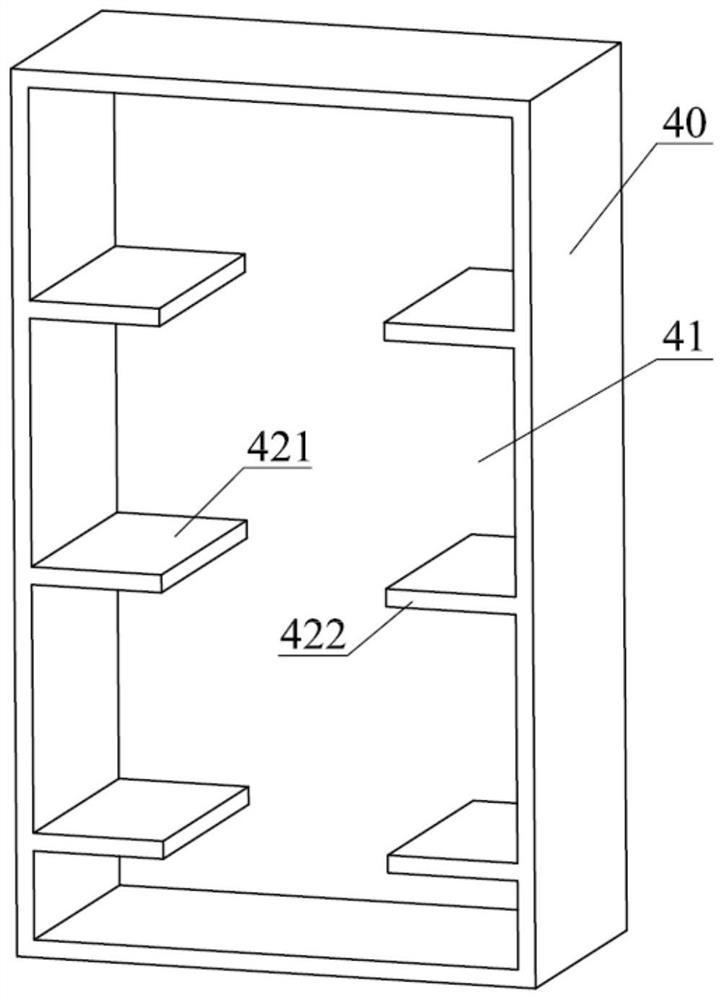

[0031] In a specific embodiment, the curing device provided by the present invention is used to cure the printed circuit on the electronic component, and the electronic component can be a silicon chip in any electronic system that needs to use a printed circuit, for example, it can be a silicon chip of a server chip, or It could be a silicon chip in a motor controller, or it could be a silicon chip in a solar cell. Those skilled in the art should know that the specific application field of the curing device and the type of specific cured electronic components do not ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com