Drying device for textile printing and dyeing

A drying device, textile printing and dyeing technology, applied in textile and papermaking, textile material processing, textile material carrier processing, etc. Uniformity etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

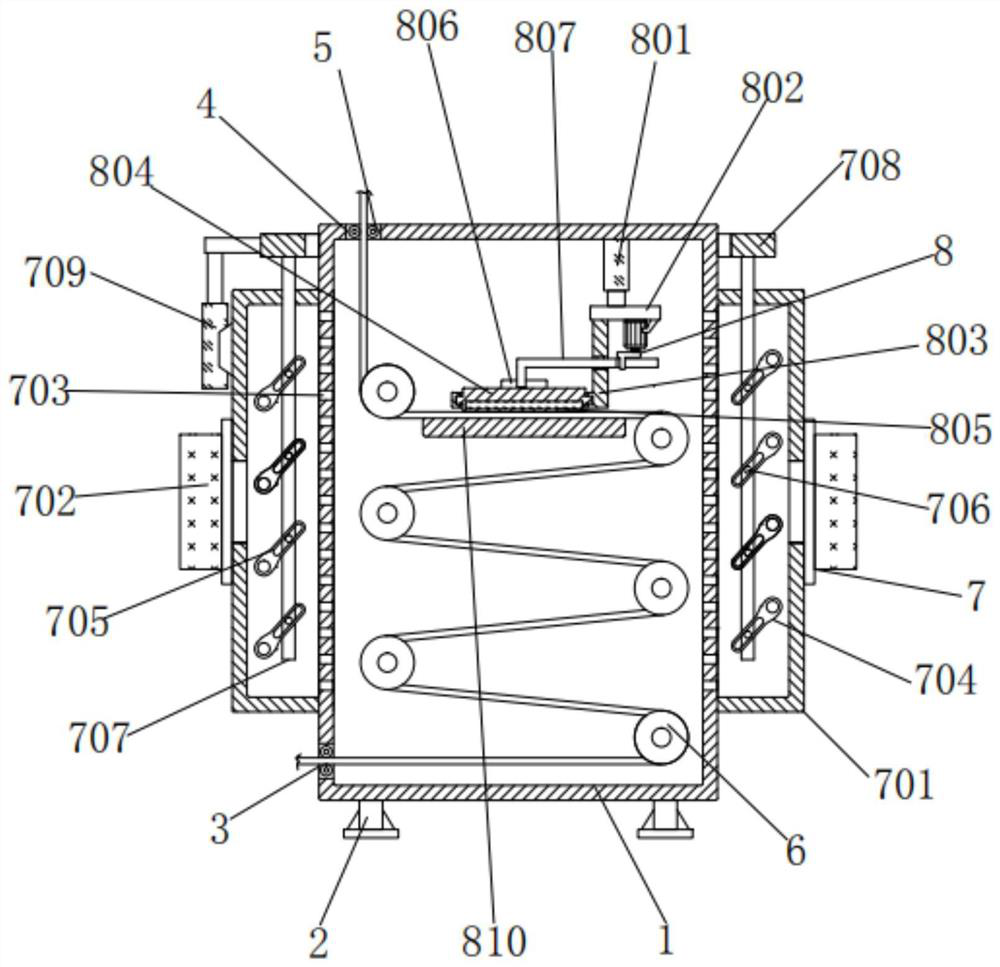

[0030] A drying device for textile printing and dyeing, comprising a box body 1, the bottom of the box body 1 is fixedly connected with a foot 2, a material inlet 3 is processed under the left end of the box body 1, and a material outlet is processed on the left side of the top of the box body 1 4. The inner walls of the feed port 3 and the discharge port 4 are rotatably connected with two round rods 5. The round rods 5 can prevent the cloth from being scratched and damaged. There are multiple round rollers 6 inside the box body 1. The round rollers 6 can be lifted The contact area between the cloth and the hot air, the round roller 6 is rotatably connected with the inner wall of the box body 1;

Embodiment 2

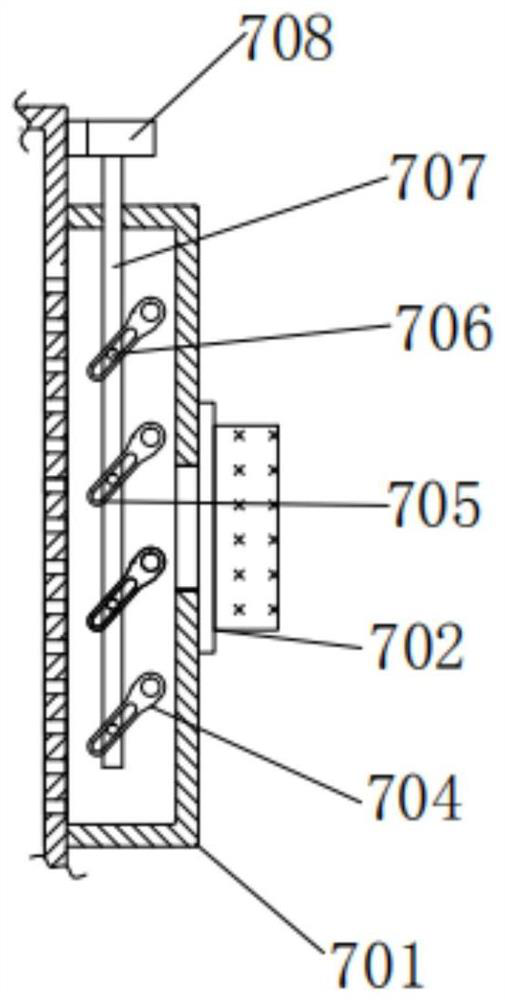

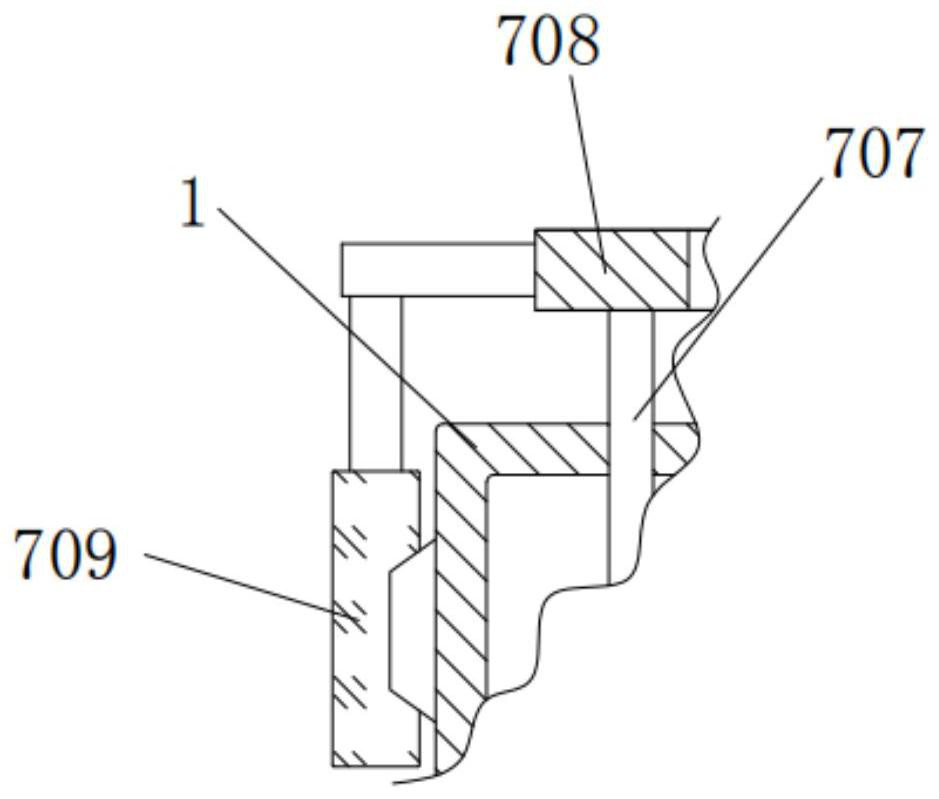

[0032] As an option, see Figure 1-3 , a drying device for textile printing and dyeing, the left and right sides of the cabinet 1 are provided with a drying assembly 7, and the drying assembly 7 includes a square cover 701, a hot air blower 702, a through hole 703, a dial 704, a round rod 705, and a through groove 706 , vertical bar 707, ring 708 and cylinder 709, the inner end of square cover 701 is fixedly connected with the left and right sides of box body 1, and the outside of square cover 701 is provided with hot air blower 702, and the model of hot air blower 702 is HAG-HP3A- 21. The air outlet end of the hot air blower 702 is connected with the outer end of the square cover 701, and the outer end of the inner end of the hot air blower 702 is fixedly connected with the outer end of the square cover 701. The inner side of the square cover 701 is provided with a through hole 703, and the through hole 703 The longitudinal range of the square cover 701 corresponds to the inn...

Embodiment 3

[0035] As an option, see figure 1 , 5And 6, the drying device for textile printing and dyeing, the inner top of the box body 1 is provided with a wrinkle removal assembly 8, and the wrinkle removal assembly 8 includes an electric push rod 801, a horizontal plate 802, a curved frame 803, a slide plate 804, an electric heating plate 805, and a clamping plate 806, the first curved rod 807, the second curved rod 808, the motor 809 and the bottom plate 810, the top of the electric push rod 801 is fixedly connected with the inner wall of the box body 1, the model of the electric push rod 801 is TG-700, and the electric push rod 801 A horizontal plate 802 is arranged below the telescopic end of the horizontal plate 802, and the top of the horizontal plate 802 is fixedly connected with the telescopic end of the electric push rod 801. The left end of the horizontal plate 802 is fixedly connected with a curved frame 803, and the left end of the curved frame 803 is equipped with a slide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com