Production method of 1,3-olein-2-palmitin

A palmitic acid triglyceride and production method technology, applied in the first field, can solve the problems of scarcity of raw materials, high production cost, and infeasibility of large-scale production, and achieve the effects of reduced consumption, small investment in equipment, and green products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

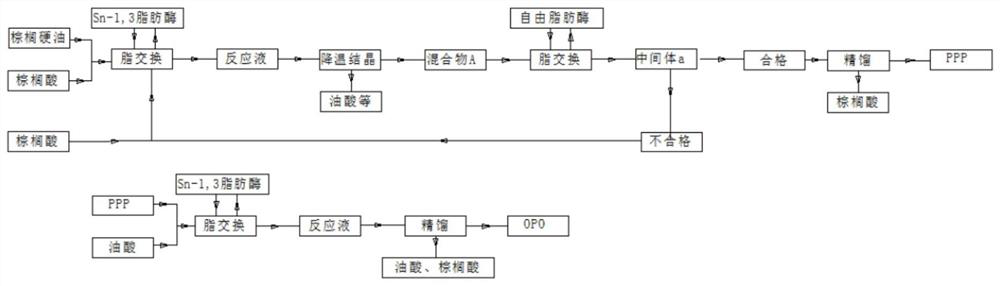

Method used

Image

Examples

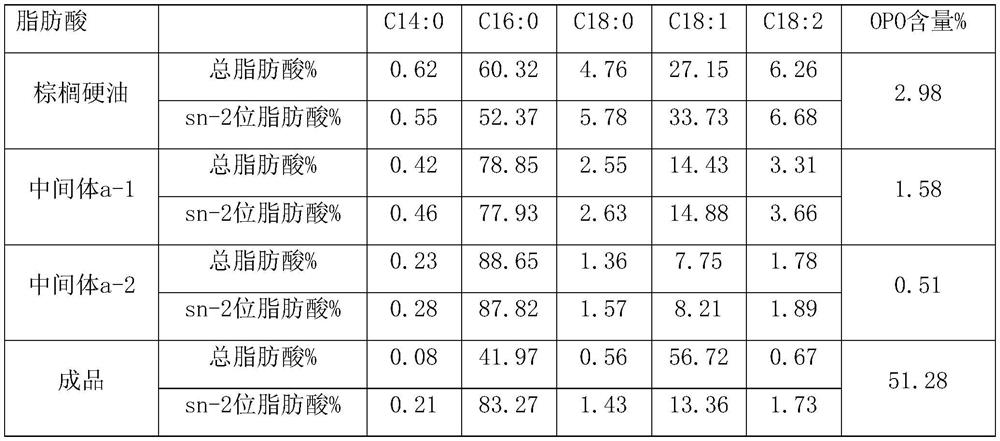

Embodiment 1

[0040] This embodiment provides a kind of production method of 1,3-dioleic acid-2-palmitic acid triglyceride, and its production method comprises the following steps:

[0041] a) Using palm hard oil as the main raw material, mix palmitic acid and Sn-1,3-specific lipase in a mass ratio of 1:3:0.06 and put it into a stainless steel reaction kettle, start stirring, raise the temperature to 65°C, and keep it warm for 120 minutes ;

[0042] b) Filter the reaction solution to recover Sn-1,3-specific lipase; cool the reaction solution at a rate of 3°C / min, and when the temperature drops to 30-35°C, keep it warm for 60 minutes to carry out cooling and crystallization, degreasing and exchanging Impurities such as oleic acid, linoleic acid and myristic acid replaced in the reaction obtain a mixture A of triglycerides and palmitic acid with high palmitic acid content;

[0043] c) Put mixture A: free invertase in a stainless steel reaction kettle at a mass ratio of 1:0.06, start stirring...

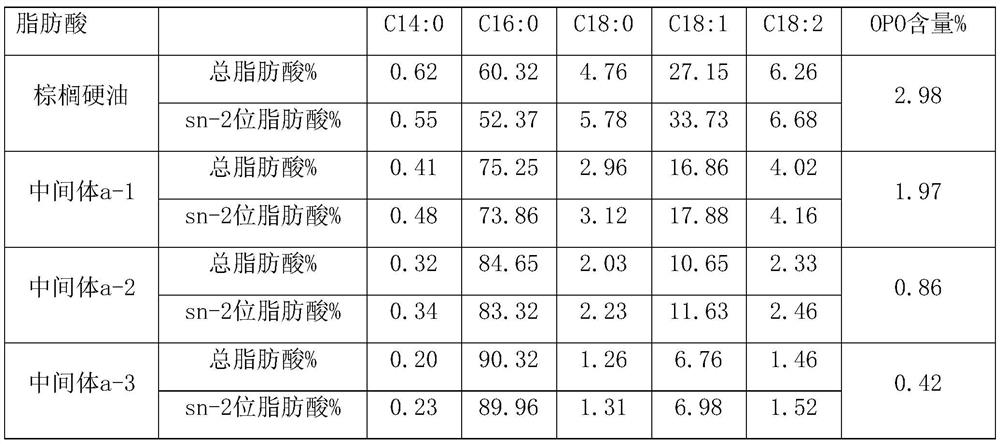

Embodiment 2

[0053] This embodiment provides a kind of production method of 1,3-dioleic acid-2-palmitic acid triglyceride, and its production method comprises the following steps:

[0054] a) Using palm hard oil as the main raw material, mix palmitic acid and Sn-1,3-specific lipase in a mass ratio of 1:2:0.05 into a stainless steel reaction kettle, start stirring, heat up to 65°C, and keep warm for 120 minutes ;

[0055] b) Filter the reaction solution to recover Sn-1,3-specific lipase; cool the reaction solution at a rate of 3°C / min, and when the temperature drops to 30-35°C, keep it warm for 60 minutes to carry out cooling and crystallization, degreasing and exchanging Impurities such as oleic acid, linoleic acid and myristic acid replaced in the reaction obtain a mixture A of triglycerides and palmitic acid with high palmitic acid content;

[0056] c) Put mixture A: free invertase in a stainless steel reaction kettle at a mass ratio of 1:0.06, start stirring, heat up to 65°C, and keep ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com