Mirabilite ore leaching liquid preparation system

A kind of mirabilite ore and leaching technology, applied in the direction of alkali metal sulfite/sulfite, alkali metal compound, inorganic chemistry, etc., can solve the problem of leaching slag (large liquid entrainment loss, small processing capacity, low year-on-year production capacity) and other problems, to achieve the effect of reducing the entrainment loss of residual precious liquid, reducing the entrainment of residual liquid, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

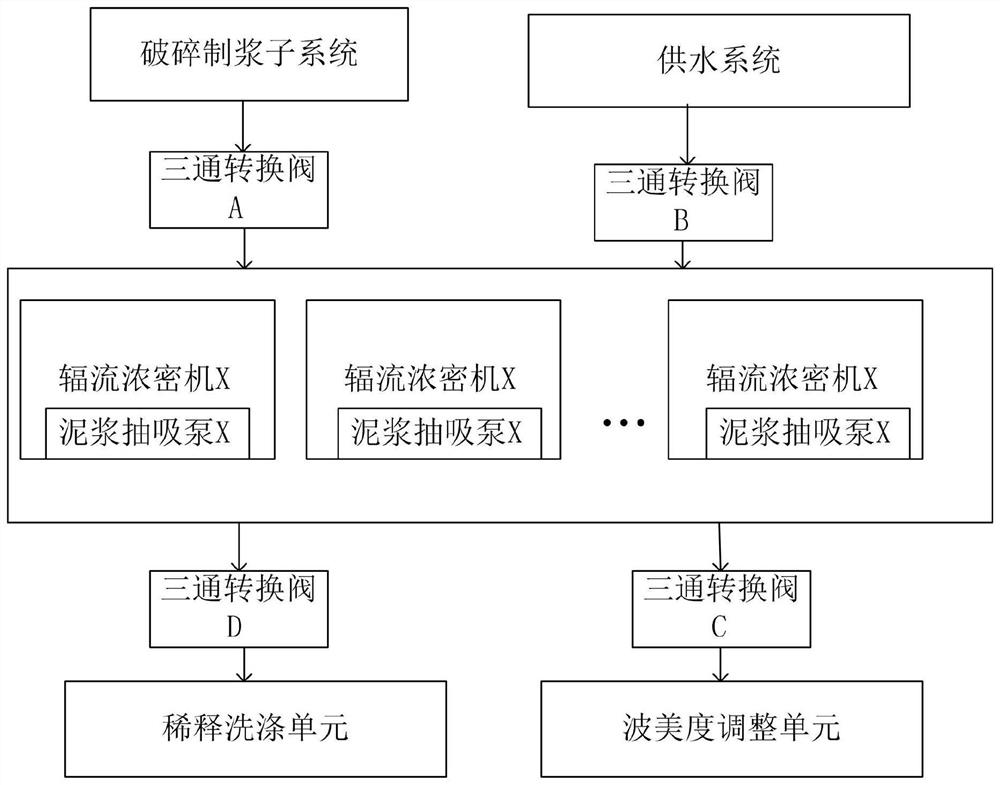

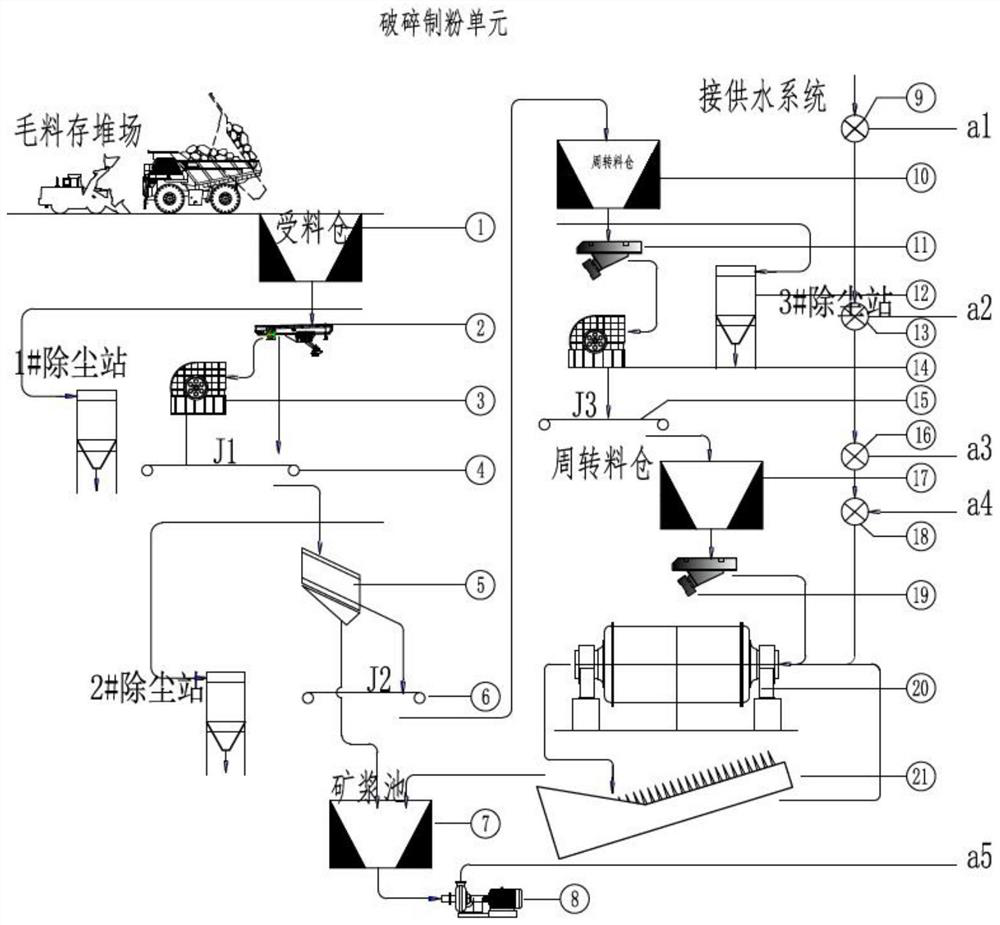

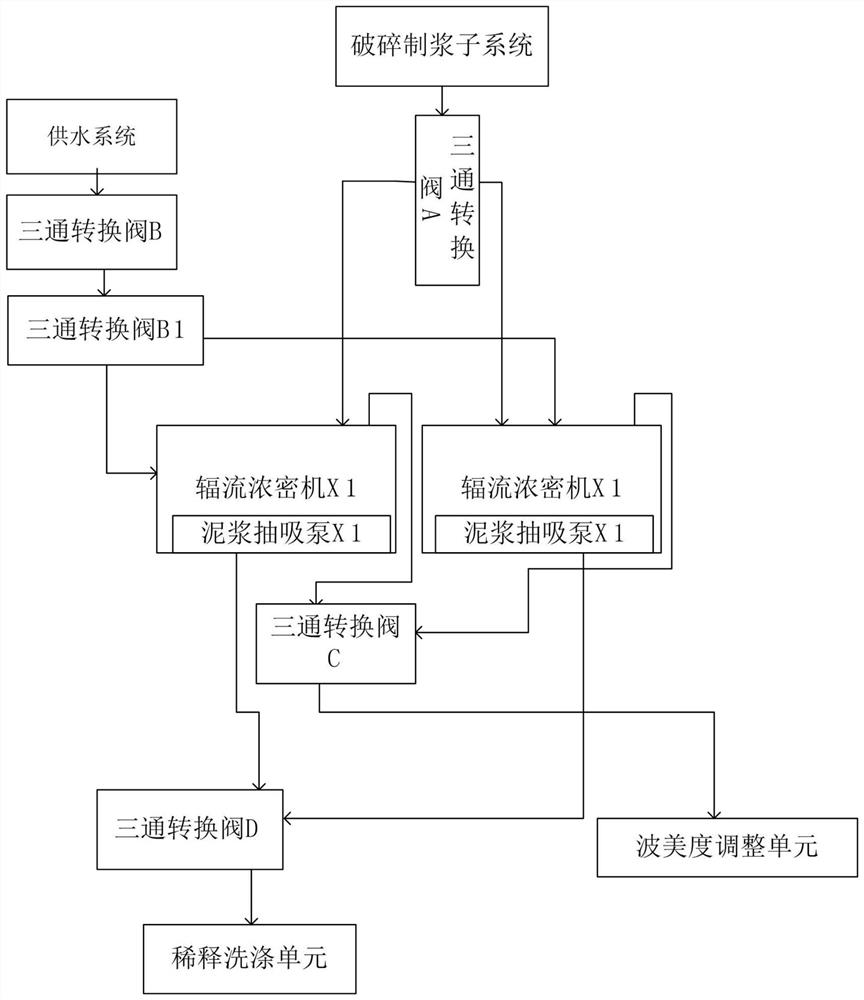

[0102]The invention consists of a crushing pulping subsystem, a leaching liquid making subsystem, and a dewatering cake making subsystem. The leaching liquid making subsystem includes two or more radial thickeners to form a leaching unit and one or more radial thickeners. The dilution washing unit, the Baume degree adjustment unit composed of two or more radial flow thickeners. In this embodiment, two radial flow thickeners are set in parallel through the leaching liquid production subsystem, and the dilution washing unit passes through two radial flow thickeners. The thickeners are connected in series, the Baume degree adjustment unit is equipped with two radial thickeners in parallel, and the dehydration cake making subsystem is equipped with 3 high-pressure mud pumps in parallel. The overall structure is connected as followsFigure 13 Shown.

[0103]Among them, the crushing and pulping subsystem is used for crushing, screening, ball milling and pulverizing the mirabilite ore to a cer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com