A welding quality detection device for natural gas distributed energy pipeline network

A technology of distributed energy and welding quality, applied in gas/liquid distribution and storage, pipeline system, spring/shock absorber, etc. The effect of small friction shocks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following is attached Figure 1-7 The application is described in further detail.

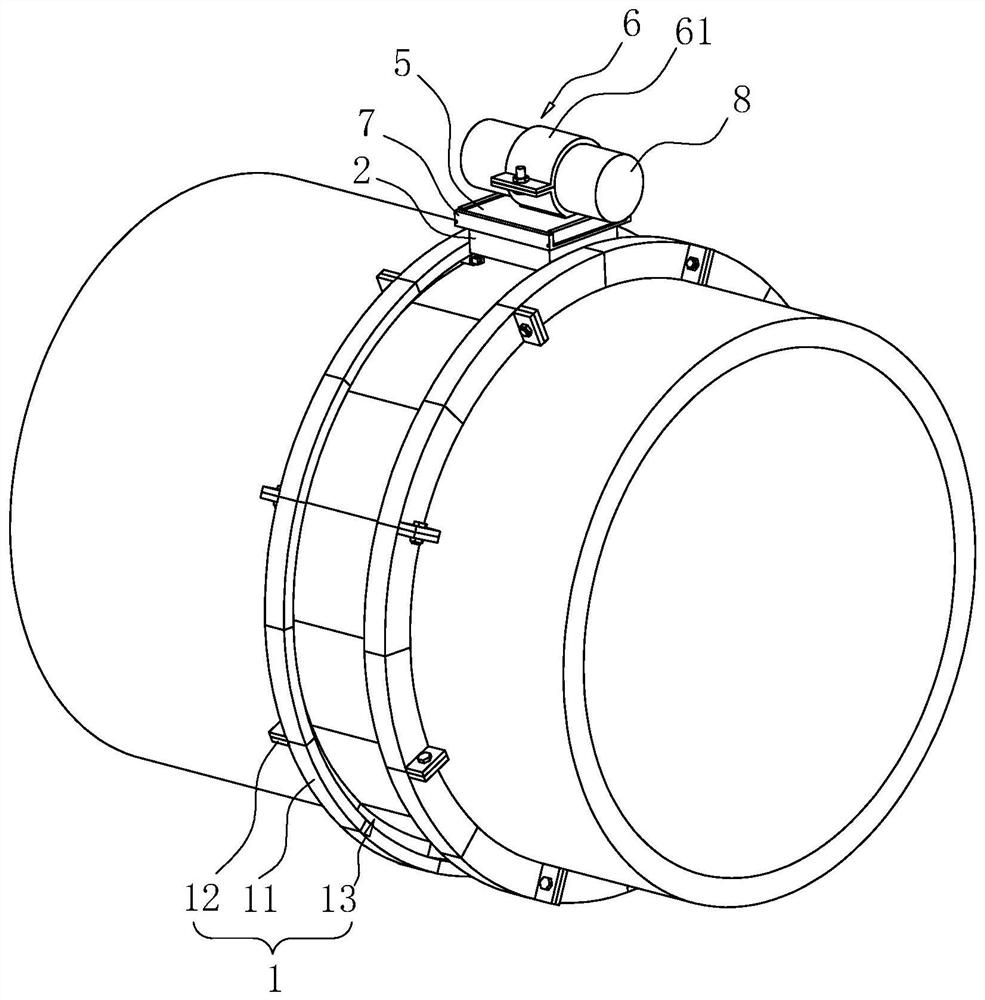

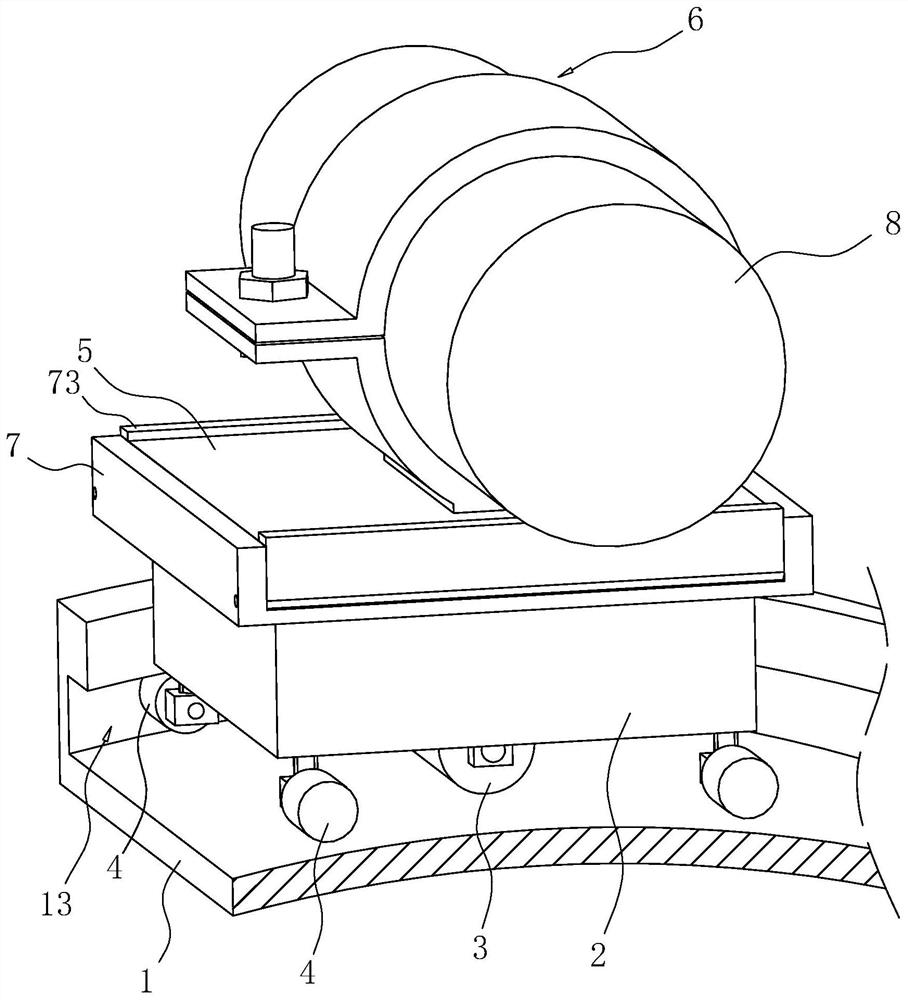

[0040] The embodiment of the present application discloses a welding quality detection device for a natural gas distributed energy pipeline network. refer to figure 1 , the detection device includes a track 1, the track 1 is assembled by a plurality of sub-tracks 11, the sub-tracks 11 are soft materials, and the two ends of each sub-track 11 are provided with connecting plates 12, when two sub-tracks 11 When the ends are spliced together, the two connecting plates 12 are fixed by bolts. And the upper surfaces of two adjacent sub-tracks 11 are connected, so the track 1 surrounds the outer wall of the pipeline, and the number of sub-tracks 11 can be increased or decreased according to the pipe diameter of the pipeline.

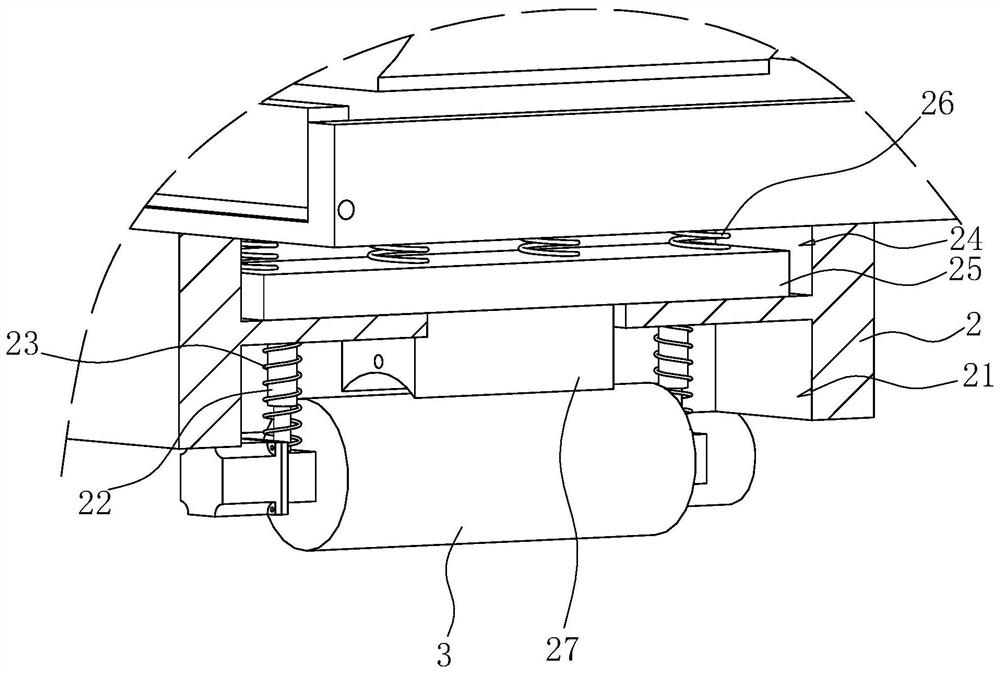

[0041] The upper surface of the track 1 has a chute 13 extending along its length extension direction, and the opening width of the chute 13 is smaller than the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com