Low-pressure waste gas recirculating system suitable for biodiesel engine and control method

A technology of recirculation system and exhaust gas recirculation rate, applied in the direction of exhaust gas recirculation, engine control, electrical control, etc., to achieve the effect of improving efficiency and reducing NOX emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

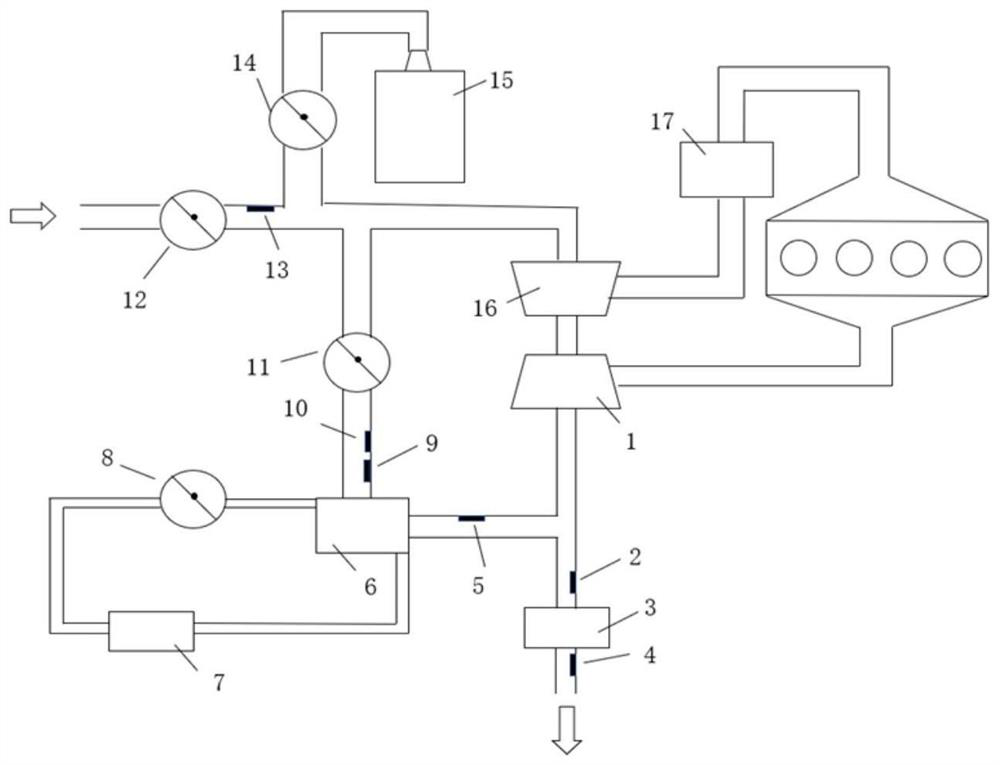

[0028] This embodiment provides a low-pressure exhaust gas recirculation system suitable for biodiesel engines, such as figure 1 As shown, the biodiesel engine includes an exhaust pipeline, an intake pipeline and a low-pressure exhaust gas recirculation system (Exhaust Gas Re-circulation, EGR). The exhaust pipeline includes a turbine 1 and a selective catalytic reduction device 3 (selective catalytic reduction, SCR), and the gas is discharged through the turbine 1 and the selective catalytic reduction device 3 in sequence. The intake pipeline includes a throttle valve 12, an oxygen valve 14, an oxygen tank 15, a supercharger 16 and a supercharged intercooler 17, and the gas passes through the throttle valve 12 and the supercharger 16 to the exhaust pipeline in sequence, or passes through the throttle valve in sequence 12. From the supercharger 16 and supercharged intercooler 17 to the exhaust pipeline, the oxygen valve 14 and the oxygen tank 15 form an oxygen branch circuit, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com