Burner arrangement method and arrangement structure for power station boiler

A power plant boiler and combustion method technology, applied in the direction of combustion method, combustion using block fuel and liquid fuel, combustion using block fuel and gaseous fuel, etc. Low interference ability, high local combustion intensity and other problems, to achieve the effect of increasing anti-interference ability, less NOx emission, and high combustion stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

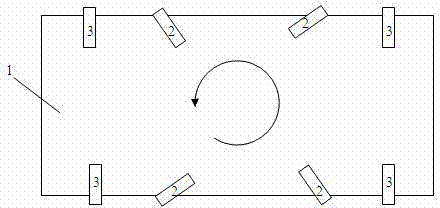

[0018] Embodiments of the invention: as figure 1 As shown, the burner arrangement method of the utility boiler is to arrange the pulverized coal burner in the way of tangential combustion and opposite combustion. The specific method is that the tangential combustion is located in the center of the furnace, and four pulverized coal burners located in the center of the furnace form a four-corner tangential combustion technology; the opposing combustion is located on both sides of the furnace, and one or two symmetrical pulverized coal burners can be installed on each side , forming a hedging combustion technique.

[0019] The burner arrangement structure of the power plant boiler is as follows: a pulverized coal burner 2 is arranged on the front and rear walls of the furnace 1, and four pulverized coal burners 2 are arranged at the center of the front and rear walls of the furnace 1 to form a tangent circle, forming a four-cornered tangent circle. Combustion technology structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com