PM (particle matter) trapping and back-flushing circulator

A circulator and particulate technology, applied in exhaust gas recirculation, machine/engine, fuel air filter, etc., can solve the problems of increased back pressure of internal combustion engine, high cost, harm to human health, etc., to reduce NOx emissions, eliminate The effect of reducing engine power and purifying the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

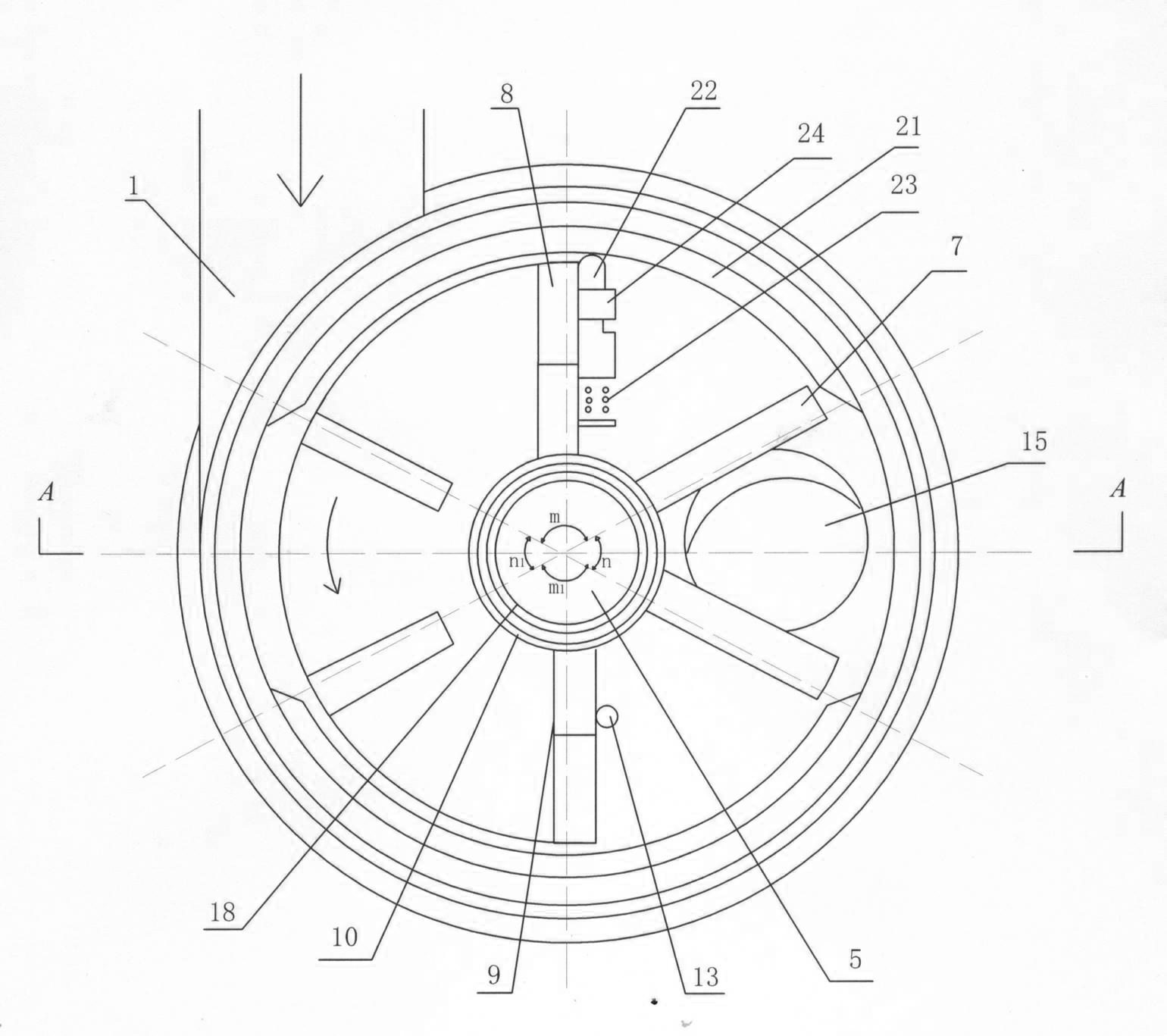

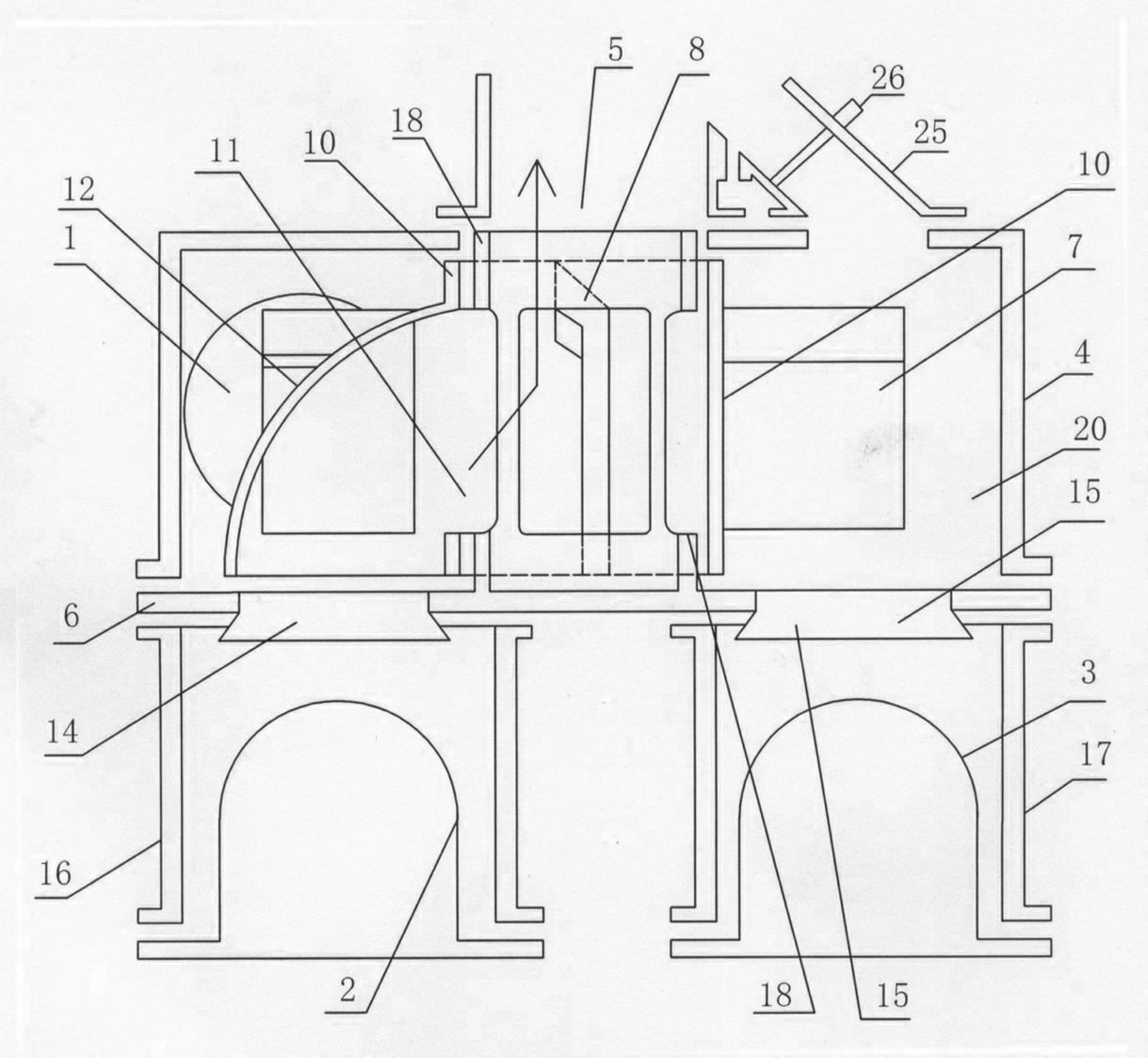

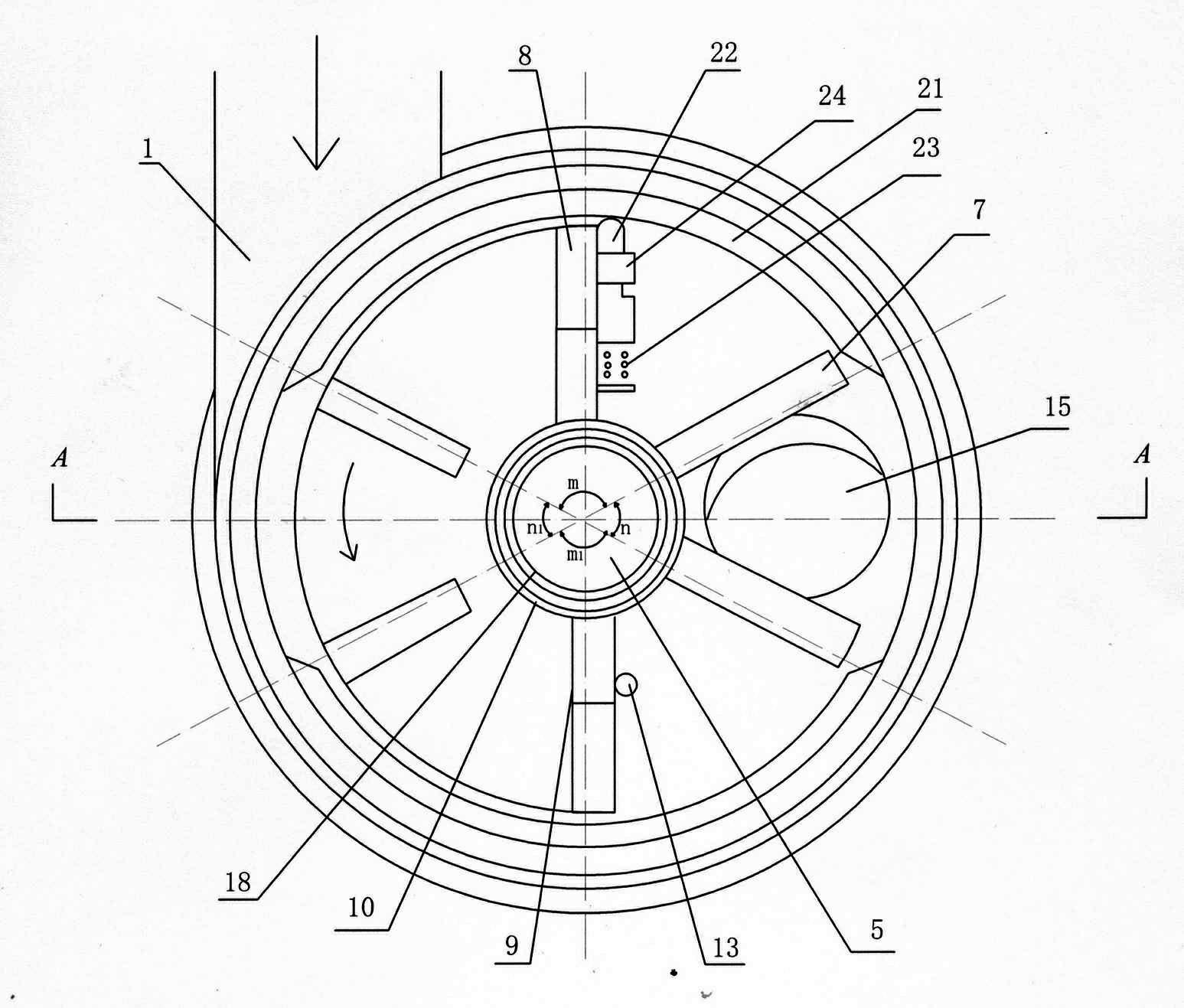

[0013] The accompanying drawings have shown the structure of the present invention and its embodiments, and further describe the relevant details of the embodiments below in conjunction with the accompanying drawings.

[0014] This microparticle catches blow-back circulator, has a flow conversion chamber 20 that is surrounded by housing 4 and base plate 6, and in the flow conversion chamber there is a uniformly distributed blade 7, 8, 9, etc., paddle (this embodiment 6 paddles), a curved cover plate 12 and a sleeve shaft 10 with an opening on one side form an integral rotating air intake channel 11, and the two ends of the sleeve shaft 10 are sleeved on the tube shaft 18 integrated with the base plate 6, and the sleeve Both ends of the shaft 10 are rotated by means of a tube shaft 18 .

[0015] When the engine starts to inhale, and the air enters from the filter bag assembly 2 on the left side, the particles in the atmosphere are captured on the filter bag assembly 2, and wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com