A self-balancing continuous unscrewing and unloading drill pipe threading device

A self-balancing, drill pipe technology, applied in drill pipe, drill pipe, earth-moving drilling, etc., can solve the problem that the unscrewing tool cannot achieve smooth unscrewing, and achieve the effect of great significance and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to illustrate the present invention more clearly, the present invention will be further described below in conjunction with preferred embodiments and accompanying drawings. It should be understood by those skilled in the art. The content specifically described below is illustrative rather than restrictive, and should not limit the protection scope of the present invention. In order not to obscure the essence of the present invention, well-known methods, procedures, procedures, components and circuits have not been described in detail.

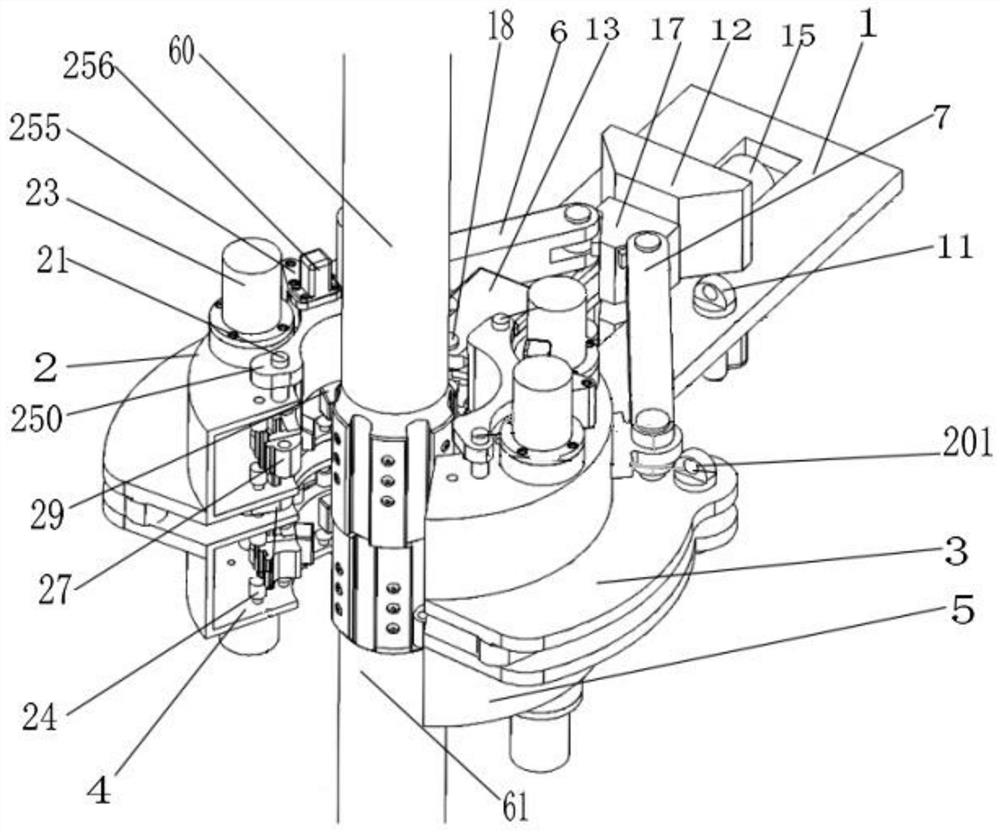

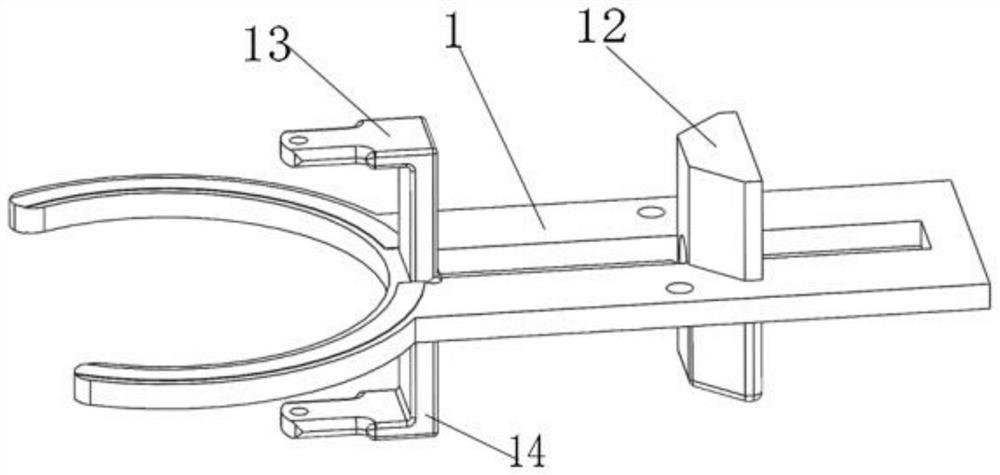

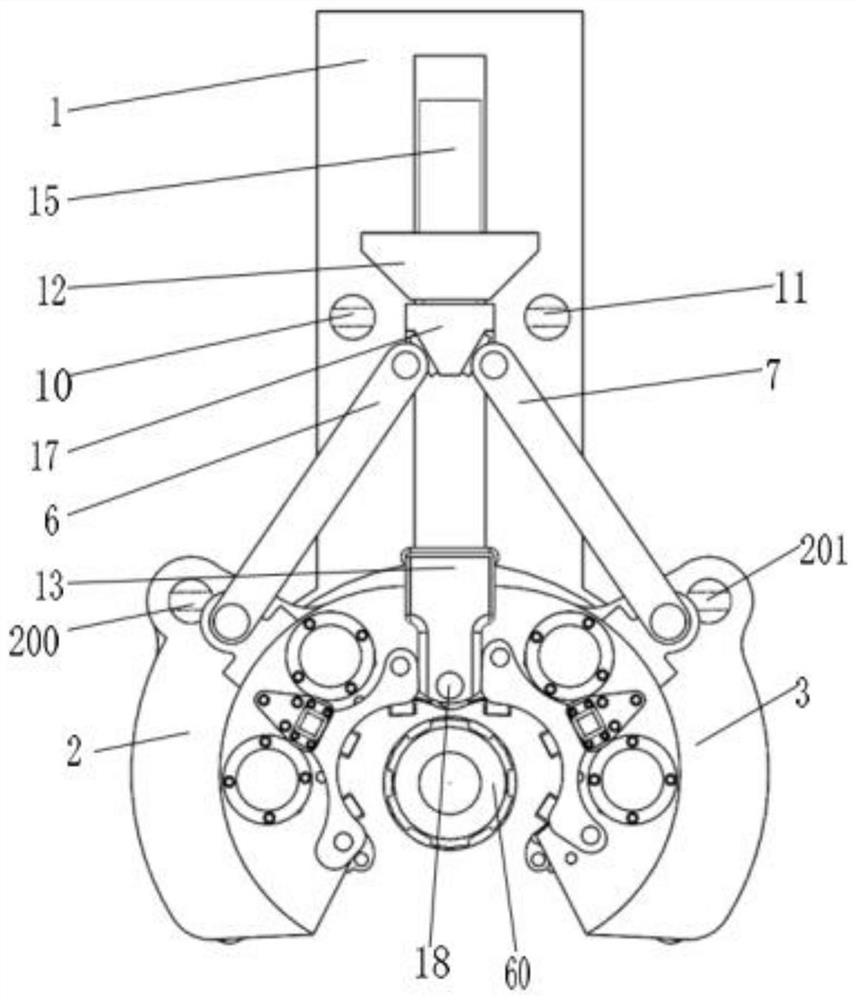

[0037] A self-balancing continuous unscrewing drill pipe threading device, comprising a cantilever support 1, an upper left unscrewing assembly 2, an upper right unscrewing assembly 3, a lower left unscrewing assembly 4 and a lower right unscrewing assembly 5;

[0038] The upper left unscrewing assembly 2 has the same structure as the lower right unscrewing assembly 5;

[0039] The lower left unscrewing assembly 4 and the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com