Green extraction method of ionic rare earth ore calcium salt system

An ion-type rare earth ore and extraction method technology, which is applied in the field of green extraction of ion-type rare earth ore calcium salt system, can solve the problems of high processing and recovery costs, low content of valuable elements, difficult process control, etc., and achieve the improvement of leaching rate and rare earth The effect of leaching peak concentration, low product impurity content and shortening leaching time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] This embodiment provides a green extraction method of ionic rare earth ore calcium salt system, comprising the following steps:

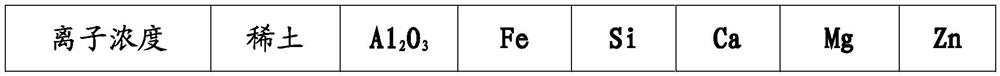

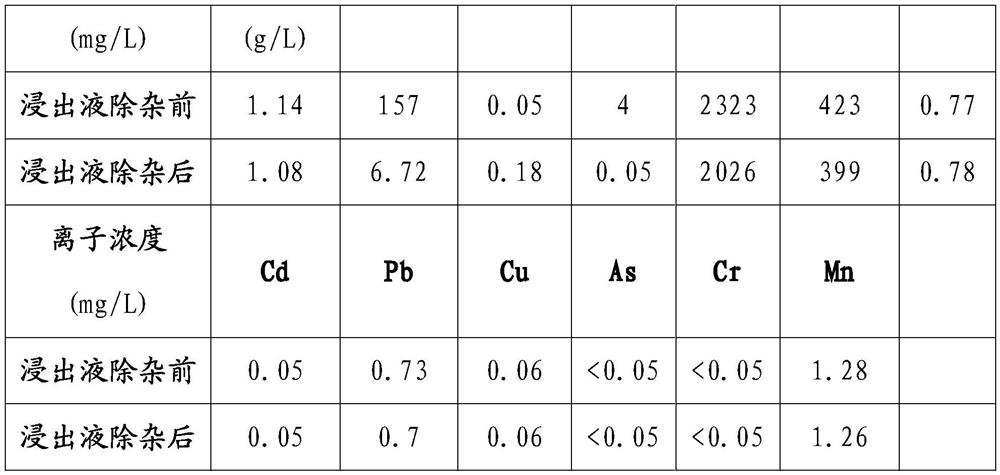

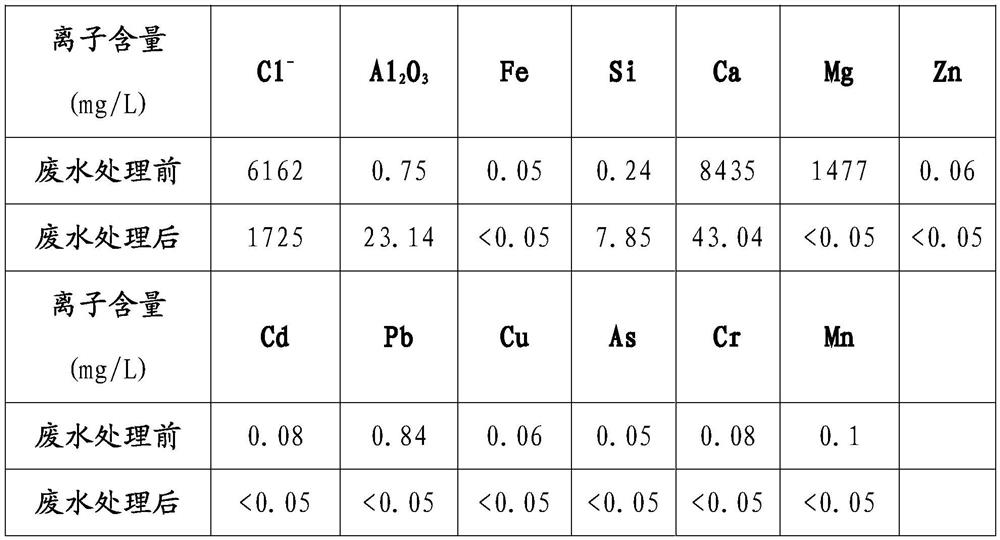

[0022] (1) Rare earth leaching: Taking Guangdong Xinfeng ionic rare earth mine as a sample, the ionic phase rare earth grade of the ore soil is determined to be 0.054%, and 1.8kg of ore soil is taken, which contains 0.972g of rare earth, and the diameter of the ore soil is 66mm. In the glass column, the height of ore soil in the column is 32.8cm. According to 14.8 times of the rare earth weight in the ore soil, a total of 14.4g of the leaching agent is required. Aluminum chloride is used as the acid regulator, calcium chloride and the acid regulator are configured into a leaching agent in a weight ratio of 9:1, and a total of 360ml of a leaching agent solution with a mass concentration of 4% of the ore leaching agent is obtained. The ore leaching agent solution is added into the ore soil for ore leaching, and the ore leaching solution is col...

Embodiment 2

[0033] This embodiment provides a green extraction method of ionic rare earth ore calcium salt system, comprising the following steps:

[0034] (1) Rare earth leaching: Taking Guangdong Xinfeng ionic rare earth mine as a sample, the ionic phase rare earth grade of the ore soil is determined to be 0.069%, and 3.6kg of ore soil is taken, which contains 2.484g of rare earth, and the diameter of the ore soil is 64mm. In the glass column, the height of ore soil in the column is 69.99cm. According to 11.6 times of the rare earth weight in the ore soil, the leaching agent needed is 28.8g. Adopt aluminum chloride as the acid regulator, calcium chloride and the acid regulator are configured into a leaching agent in a weight ratio of 9:1, and a total of 720ml of a leaching agent solution with a mass concentration of the leaching agent of 4% is configured. The ore leaching agent solution is added into the ore soil for ore leaching, and the ore leaching solution is collected. The volume...

Embodiment 3

[0043] This embodiment provides a green extraction method of ionic rare earth ore calcium salt system, comprising the following steps:

[0044] (1) Taking Guangdong Xinfeng ionic rare earth mine as a sample, the ionic phase rare earth grade of the ore soil is determined to be 0.054%. Take 1.8kg of ore soil, which contains 0.972g of rare earth, and put the ore soil into a glass column with a diameter of 100mm , The height of ore soil in the column is 143mm. Calculate the total amount of required calcium salt and acid-adjusting agent as 18.5 times of the weight of rare earth in the ore to be 18g in total. Ferric chloride is used as the acid-adjusting agent, and calcium chloride and acid-adjusting agent are configured in a weight ratio of 19:1. ore leaching agent, and a total of 360ml of ore leaching agent solution with a mass concentration of 5% ore leaching agent is configured. Add the leaching agent solution into the ore soil for leaching, collect the leaching solution, measu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com