Stabilizing heat treatment method for TP347 thick-wall pipeline

A technology for stabilizing heat treatment and piping, applied in heat treatment furnaces, heat treatment equipment, heat treatment process control and other directions, it can solve the problems of large thermal stress, uneven temperature, and high outer wall temperature, achieve uniform stress distribution, reduce residual stress, reduce The effect of stress peaks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] A TP347 thick-walled pipe stabilization heat treatment method of the present invention will be described in detail below in conjunction with the embodiments and the accompanying drawings.

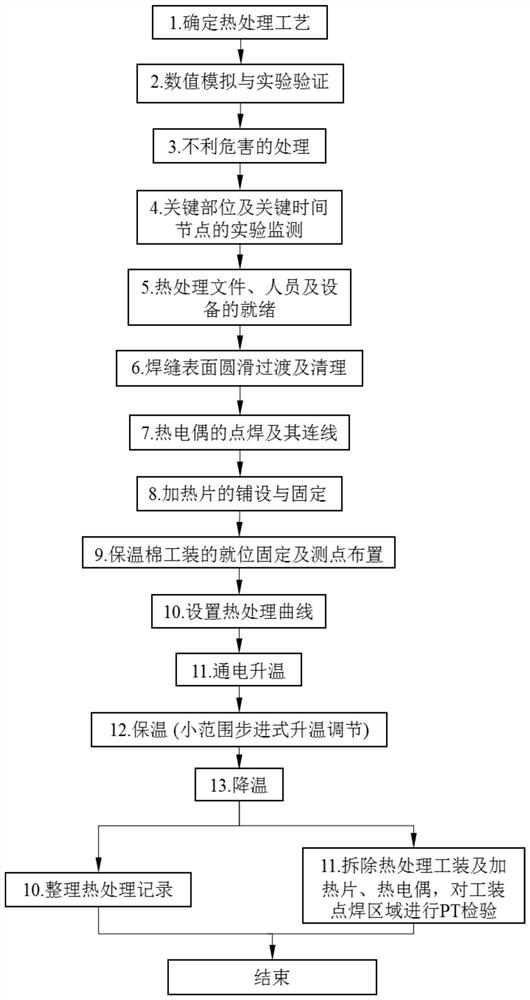

[0055] Such as figure 1 Shown, a kind of TP347 thick-walled pipe stabilization heat treatment method of the present invention comprises the steps:

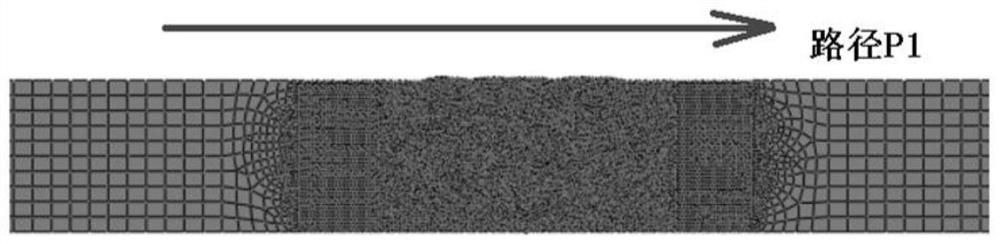

[0056] 1) Determining the heat treatment process is to determine the process parameters of heat treatment through finite element simulation analysis, including:

[0057] (1.1) Calculate the heating rates of 60°C / h, 120°C / h, 180°C / h, and 240°C / h respectively, and compare the stress fields under the four heating rates. The stress field with the smallest stress peak value and uniform stress distribution is Judging criteria to get the optimal heating rate;

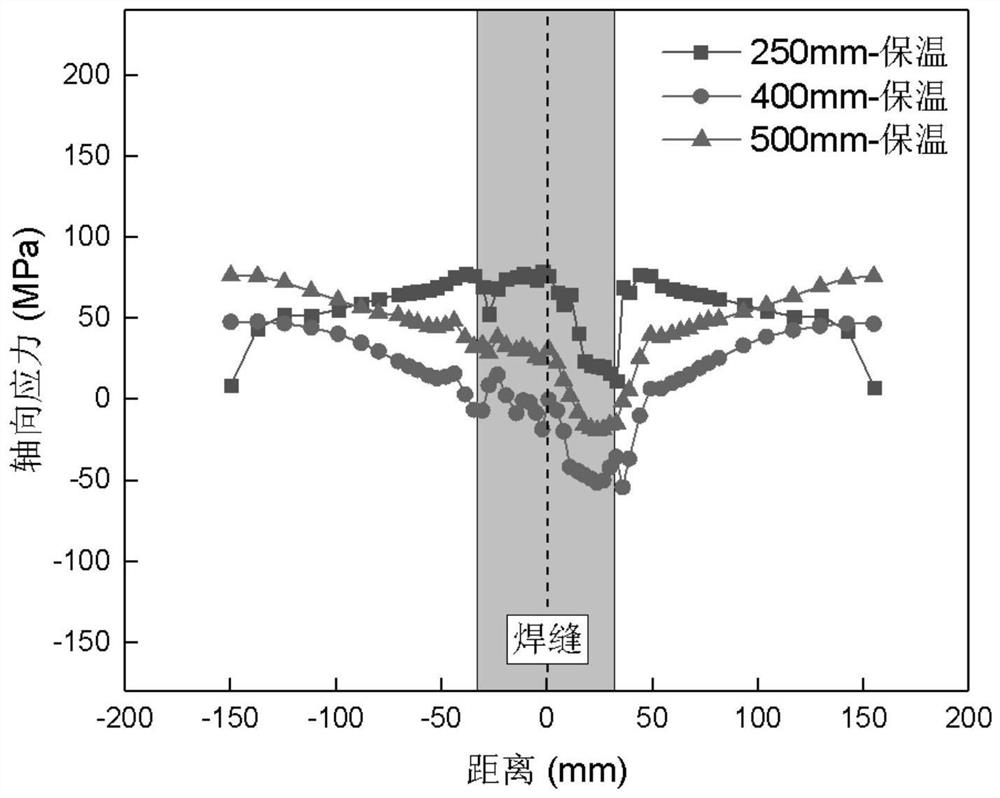

[0058] (1.2) Calculate the working conditions of heat preservation for 2h and 4h respectively, compare the stress distribution under different heat preservation times, and determine th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com