Low-temperature mold surface treatment technology

A surface treatment and mold technology, applied in the field of low-temperature mold surface treatment, can solve the problems of mold body shape change, mold scrapping, and size change, and achieve the effect of preventing shape change, facilitating heating work, and increasing temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

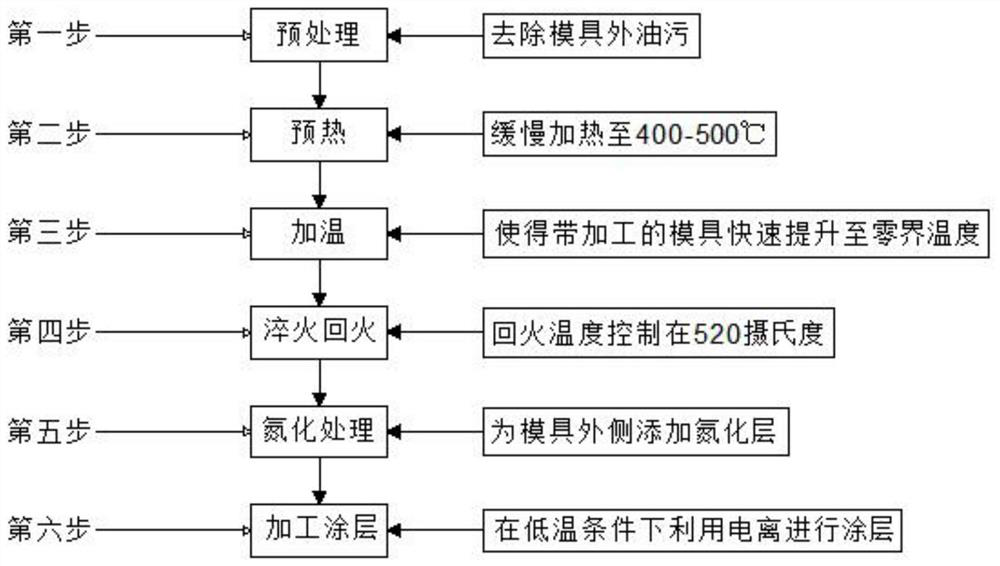

[0026] see figure 1 , the present invention provides a technical solution: a low-temperature mold surface treatment technology, specifically comprising the following steps:

[0027] The first step, pretreatment: heat the mold to be processed to 90 degrees Celsius during treatment, and then rinse the heated mold to be processed with an alkaline liquid of the same temperature for 3 minutes to initially soften the oil stains, and then place the mold to be processed Soak in the lye at the corresponding temperature for 1 hour, take out the template to be processed and rinse it in 90 degrees Celsius water for 3 minutes to remove oil, repeat soaking and rinsing several times, and finally soak it in 40 degrees Celsius water for 10 minutes, and use it again at room temperature Rinse with clean water for 5 minutes, so as to completely remove the oil stain on the outer surface of the mold, facilitate the application of the coating on the outer side of the mold, and reduce the temperature...

Embodiment 2

[0034] see figure 1 , the present invention provides a technical solution: a low-temperature mold surface treatment technology, specifically comprising the following steps:

[0035] The first step, pretreatment: heat the mold to be processed to 110 degrees Celsius during treatment, and then rinse the heated mold to be processed with an alkaline liquid of the same temperature for 4 minutes to initially soften the oil stains, and then wash the mold to be processed Soak in the lye at the corresponding temperature for 1.5 hours, take out the template to be processed and rinse it in 95 degrees Celsius water for 4 minutes to remove oil, repeat soaking and rinsing several times, and finally soak it in 45 degrees Celsius water for 10 minutes, and use it again at room temperature Rinse with clean water for 8 minutes, so as to completely remove the oil stain on the outer surface of the mold, facilitate the application of the coating on the outer side of the mold, and reduce the temperat...

Embodiment 3

[0042] see figure 1 , the present invention provides a technical solution: a low-temperature mold surface treatment technology, specifically comprising the following steps:

[0043] The first step, pretreatment: heat the mold to be processed to 130 degrees Celsius during treatment, and then rinse the heated mold to be processed with an alkaline liquid of the same temperature for 5 minutes to initially soften the oil stains, and then place the mold to be processed Soak in the lye at the corresponding temperature for 2 hours, take out the template to be processed and rinse it in 100 degrees Celsius water for 5 minutes to remove oil, repeat soaking and rinsing several times, and finally soak it in 50 degrees Celsius water for 10 minutes, and use it again at room temperature Rinse with clean water for 10 minutes, so as to completely remove the oil stain on the outer surface of the mold, facilitate the application of the coating on the outer side of the mold, and at the same time r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com