Solid toilet cleaner and preparation method

A solid toilet cleaning agent and polyethylene glycol technology, which is applied in the field of daily chemical industry, can solve the problems of difficult cleaning of urine scale, easy moisture deterioration, short service cycle, etc., and achieves strong cleaning and detergency, good bacteriostatic effect, The effect of eliminating odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

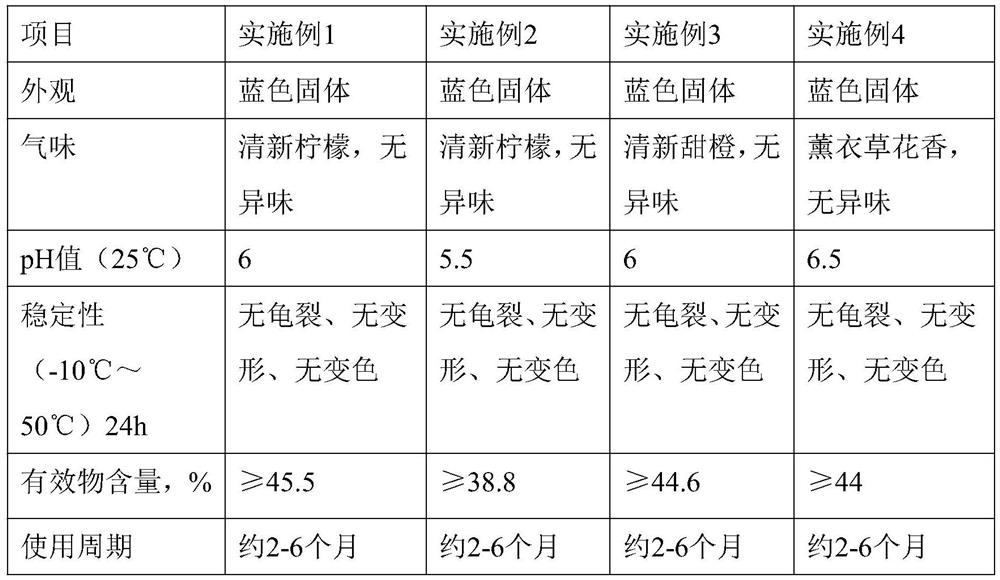

Examples

Embodiment 1

[0021]Example 1. A solid toilet cleaner, in percentage by weight: polyethylene glycol 200 10%, polyethylene glycol 4000 25%, sodium dodecylbenzene sulfonate 15%, starch 18%, sodium sulfate 20% , Citric acid 8%, brilliant blue pigment 3%, cassone 0.05%, lemon flavor 0.95%.

[0022]The preparation method is as follows:

[0023](1) Weigh each component according to the amount; heat the reactor to 90°C; add polyethylene glycol 200, polyethylene glycol 4000, sodium dodecylbenzene sulfonate, sodium sulfate, starch, lemon while stirring Acid, cool down to 65°C, add pigment, cassone, and flavor to obtain a mixture.

[0024](2) The reaction kettle and the filling equipment are kept at a constant temperature of 65°C, the mixture is filled into a bottle or mold, and solidified at room temperature to obtain a finished product.

Embodiment 2

[0025]Example 2. A solid toilet cleaner, in percentage by weight: polyethylene glycol 200 8%, polyethylene glycol 4000 30%, sodium dodecylbenzene sulfonate 12%, starch 15%, sodium sulfate 22% , Citric acid 9%, brilliant blue pigment 3.1%, casson 0.1%, lemon flavor 0.8%.

[0026]The preparation method is as follows:

[0027](1) Weigh each component according to the amount; heat the reactor to 92°C; add polyethylene glycol 200, polyethylene glycol 4000, sodium dodecylbenzene sulfonate, sodium sulfate, starch, lemon while stirring Acid, cool down to 62°C, add pigment, cassone, and flavor to obtain a mixture.

[0028](2) The reaction kettle and filling equipment are kept at a constant temperature of 62°C, the mixture is filled into a bottle or mold, and solidified at room temperature to obtain a finished product.

Embodiment 3

[0029]Example 3. A solid toilet cleaner, by weight percentage: polyethylene glycol 200 12%, polyethylene glycol 4000 20%, sodium dodecylbenzene sulfonate 18%, starch 16%, sodium sulfate 24% , Citric acid 8%, brilliant blue pigment 1%, cassone 0.1%, sweet orange flavor 0.9%.

[0030]The preparation method is as follows:

[0031](1) Weigh each component according to the amount; heat the reactor to 88°C; add polyethylene glycol 200, polyethylene glycol 4000, sodium dodecylbenzene sulfonate, sodium sulfate, starch, and lemon while stirring Acid, cool down to 66°C, add pigment, cassone, and flavor to obtain a mixture.

[0032](2) Keep the reactor and filling equipment at a constant temperature of 66°C, put the mixture into a bottle or mold, and solidify at room temperature to obtain a finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com