Hydrocyclone pretreatment type aerated grit chamber desanding system

A technology of hydrocyclone, aeration and sand settling, which is applied in special compound water treatment, biological water/sewage treatment, water/sewage multi-stage treatment, etc. It can solve the problem of loss, low separation efficiency, and influence on the settlement of sand-water separators Spiral output sand performance and other issues to achieve the effects of supplementing carbon sources, improving separation efficiency, and ensuring the safety of effluent water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] This patent proposes a hydrocyclone sand removal pretreatment type aeration grit chamber sand removal system. In order to make the purpose, technical scheme and effect of this patent clearer and clearer, the patent will be further clarified and complete in combination with specific examples below. instruction of.

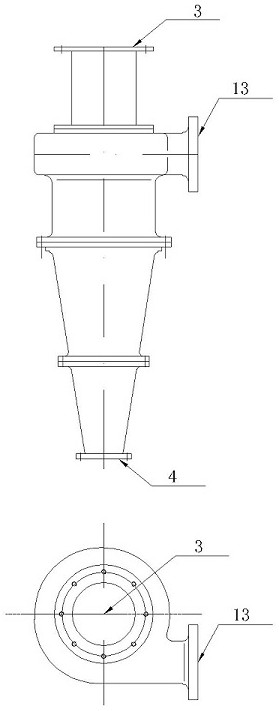

[0012] The patent of the invention is a sand-water separator after the sand-water mixture pumped by the sand-suction pump is concentrated and pretreated before the hydrocyclone sand remover participates in the discharge of the sand-suction pump in the aeration grit chamber. A new type of aerated grit chamber sand removal system for further sedimentation, sand-water separation and sand discharge.

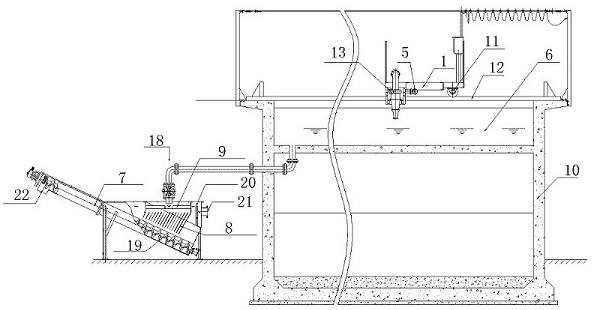

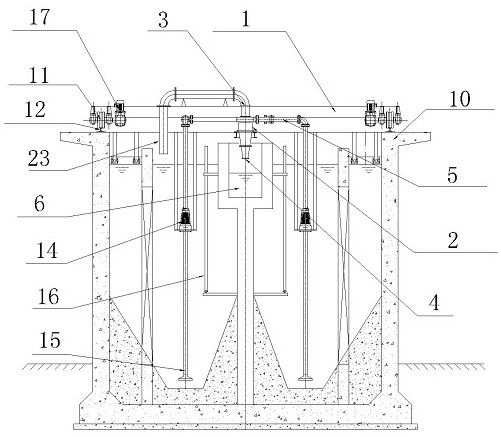

[0013] Such as figure 1 , figure 2 , image 3 As shown, the sand discharge tank 6 described in this system is arranged parallel to the rail 12 on the top of the aerated grit chamber 10, the driving sand suction bridge 1 is erected on the top rail 12 of the pool ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com