Method for preparing nano spherical oxide dispersion strengthening phase

A technology of nano-oxide and dispersion strengthening, which is applied in the field of powder metallurgy materials, can solve the problems that have not been reported, and achieve the effect of improving the nano-sized effect, increasing the elongation rate, and promoting the effect of uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

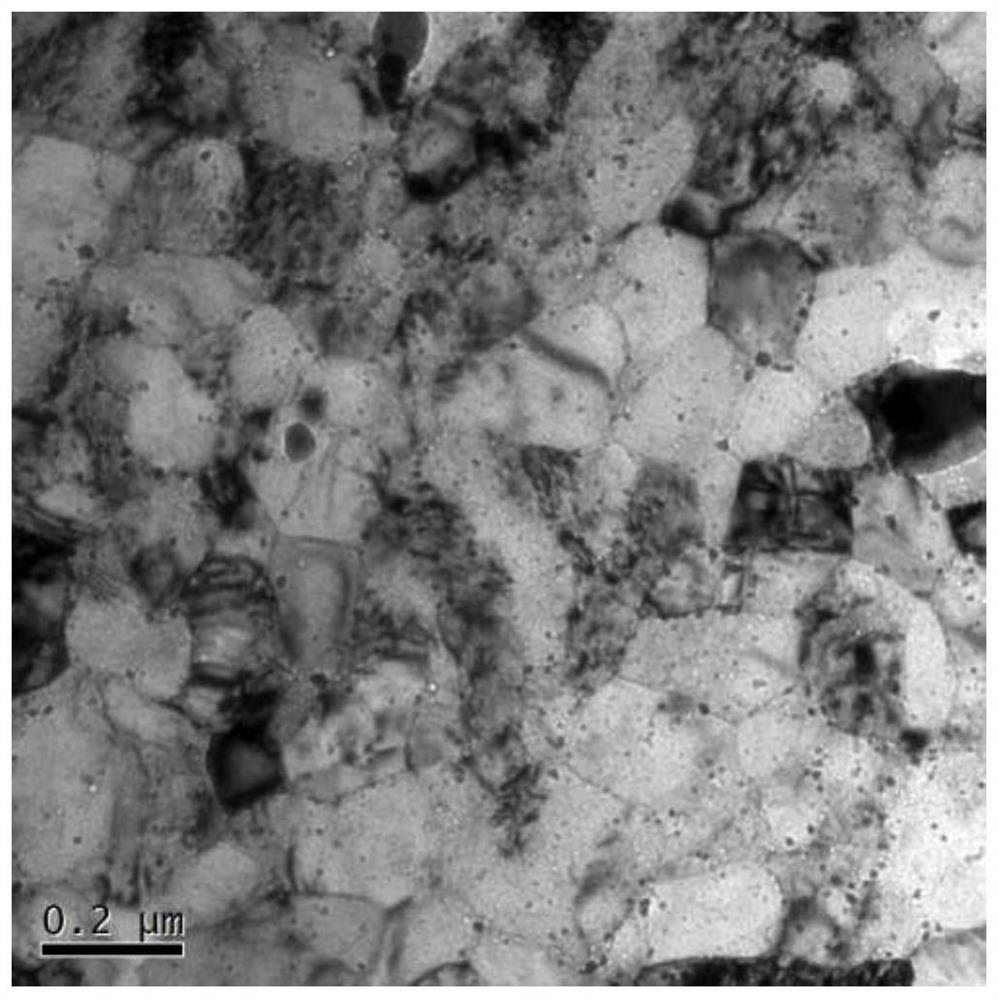

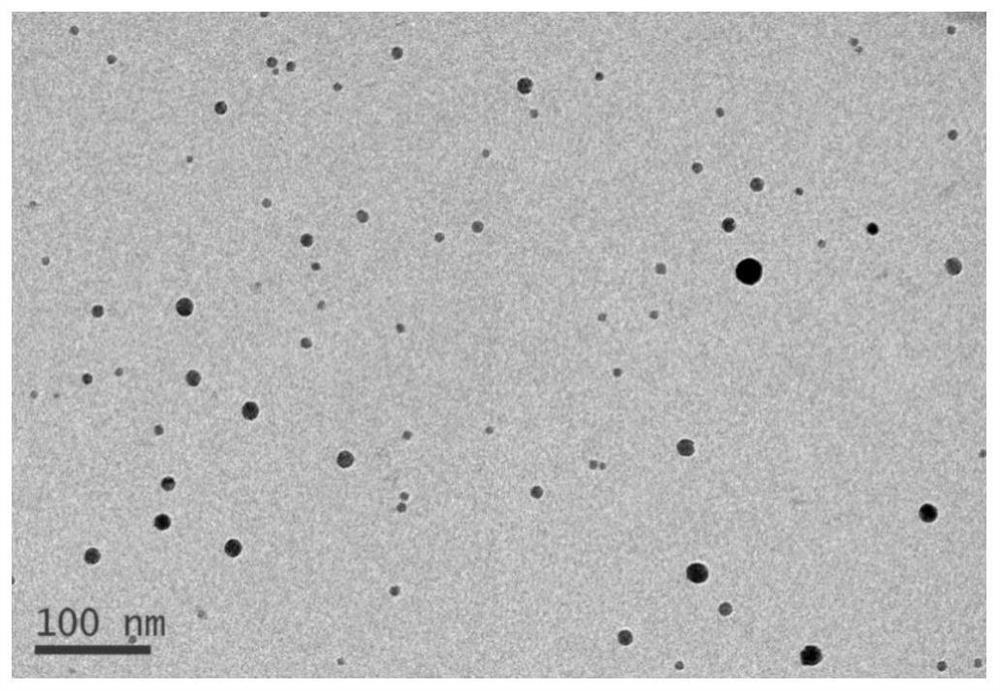

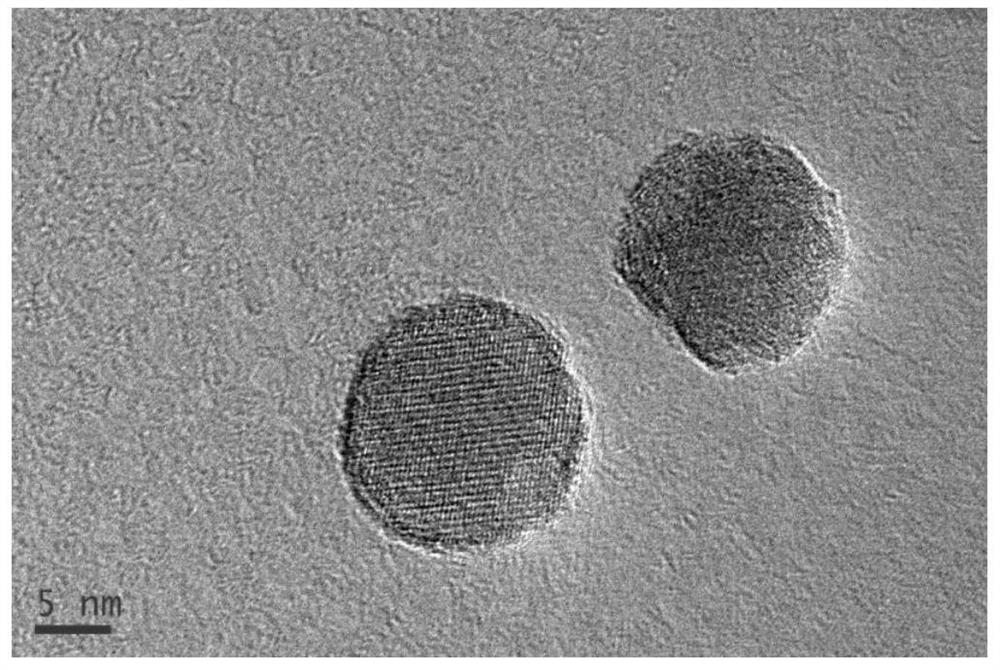

Image

Examples

Embodiment 1

[0054] Embodiment 1: Fe-14Cr-3W-0.4Ti-1.5Y 2 o 3 (wt.%) Alloy

[0055] making process:

[0056] Step 1: According to the mass ratio of 1:4, weigh Y 2 o 3 60 g of powder and 240 g of gas-atomized Fe-14Cr-3W-0.4Ti (wt.%) iron-based pre-alloyed powder are 300 g in total, and put into a ball mill jar. Among them, the iron-based pre-alloyed powder particle size is less than or equal to 150μm, Y 2 o 3 Powder particle size is less than or equal to 10μm. According to the mass ratio of ball to material 10:1, the diameter of the grinding ball is 20mm:15mm:10mm:8mm:5mm:3mm=1:1:1:1:1:1, weigh 3000g of the grinding ball and put it into the ball milling tank.

[0057] Step 2: Seal the ball mill tank, vacuumize it, the vacuum degree is less than or equal to 0.1Pa, and fill it with high-purity argon.

[0058] Step 3: Put the ball mill jar into the vertical planetary ball mill for mechanical ball milling; set the parameters of the mechanical ball mill, the rotation speed is 300r / min, a...

Embodiment 2

[0063] Embodiment 2: Fe-14Cr-3W-0.4Ti-1.0Y 2 o 3 (wt.%) Alloy

[0064] making process:

[0065] Step 1: According to the mass ratio of 1:3, weigh Y 2 o 3 75g of powder and 225g of gas-atomized Fe-14Cr-3W-0.4Ti (wt.%) iron-based pre-alloy powder are 300g in total, and put into a ball mill jar. Among them, the iron-based pre-alloyed powder particle size is less than or equal to 150μm, Y 2 o 3 Powder particle size is less than or equal to 10μm. According to the ball-to-material ratio of 12:1, the diameter of the grinding balls is 20mm:15mm:10mm:8mm:5mm:3mm=1:1:1:1:1:1, weigh 3600g of grinding balls and put them into the ball milling tank.

[0066] Step 2: Seal the ball mill tank, vacuumize it, the vacuum degree is less than or equal to 0.1Pa, and fill it with high-purity argon.

[0067] Step 3: Put the ball mill jar into the vertical planetary ball mill for mechanical ball milling; set the parameters of the mechanical ball mill, the rotation speed is 280r / min, and the mec...

Embodiment 3

[0072] Embodiment 3: Fe-14Cr-3W-0.4Ti-2.0Y 2 o 3 (wt.%) Alloy

[0073] making process:

[0074] Step 1: According to the mass ratio of 1:5, weigh Y 2 o 3 100 g of powder and 500 g of partially gas-atomized Fe-14Cr-3W-0.4Ti (wt.%) iron-based pre-alloyed powder are 600 g in total and put into a ball mill jar. Among them, the iron-based pre-alloyed powder particle size is less than or equal to 150μm, Y 2 o 3 Powder particle size is less than or equal to 10μm. According to the ball-to-material ratio of 15:1, the diameter of the grinding balls is 20mm:15mm:10mm:8mm:5mm:3mm=1:1:1:1:1:1, weigh 9000g of grinding balls and put them into the ball milling tank.

[0075] Step 2: Seal the ball mill tank, vacuumize it, the vacuum degree is less than or equal to 0.1Pa, and fill it with high-purity argon.

[0076] Step 3: Put the ball mill tank into the vertical planetary ball mill for mechanical ball milling; set the parameters of the mechanical ball mill, the rotation speed is 260r / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com