Three-dimensional porous MXene assembly, preparation method and application thereof

A three-dimensional porous and assembled technology, applied in the direction of mixing methods, chemical instruments and methods, transportation and packaging, etc., can solve the problems that are difficult to meet the requirements of efficient treatment of landfill leachate, and achieve good photocatalytic degradation of landfill leachate performance, The effect of large specific surface area and simple treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

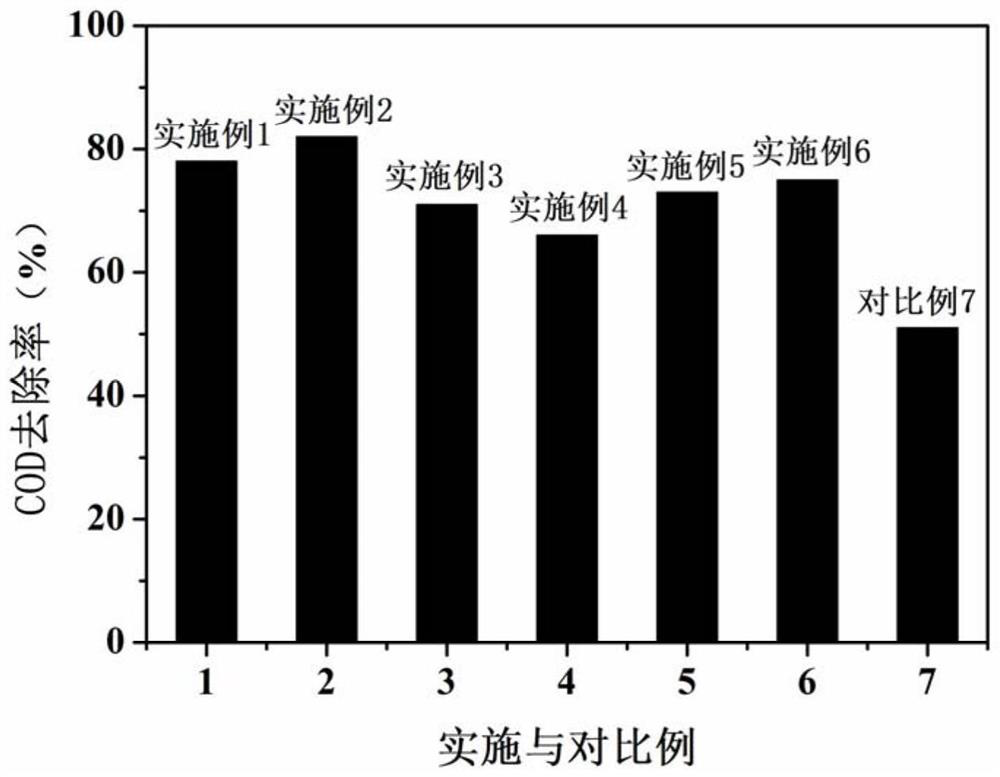

Embodiment 1

[0039] (1) Take 10mg Ti 3 C 2 Phase MXene was added to deionized water, and 2 mg / mL MXene aqueous dispersion was prepared by ultrasonic dispersion; 10 mg / mL AgNO was added dropwise at 1000 rpm 3 Aqueous solution, in situ construction of Ag / TiO by redox reaction 2 / MXene composite catalyst, where AgNO 3 The mass ratio to MXene is 1:8.

[0040] (2) Add 20 mg of SA into deionized water, heat and stir at 80°C to prepare a 4 mg / mL SA aqueous solution.

[0041] (3) 5mL of the Ag / TiO 2 / MXene dispersion and 5mL of the SA aqueous solution were mixed, stirred at 200rpm for 20min; 2 in a 100mL beaker, chemically cross-linked for 4h, then placed in liquid nitrogen for quick freezing for 10min, and freeze-dried for 24h under vacuum to obtain Ag / TiO 2 / MXene / SA assembly.

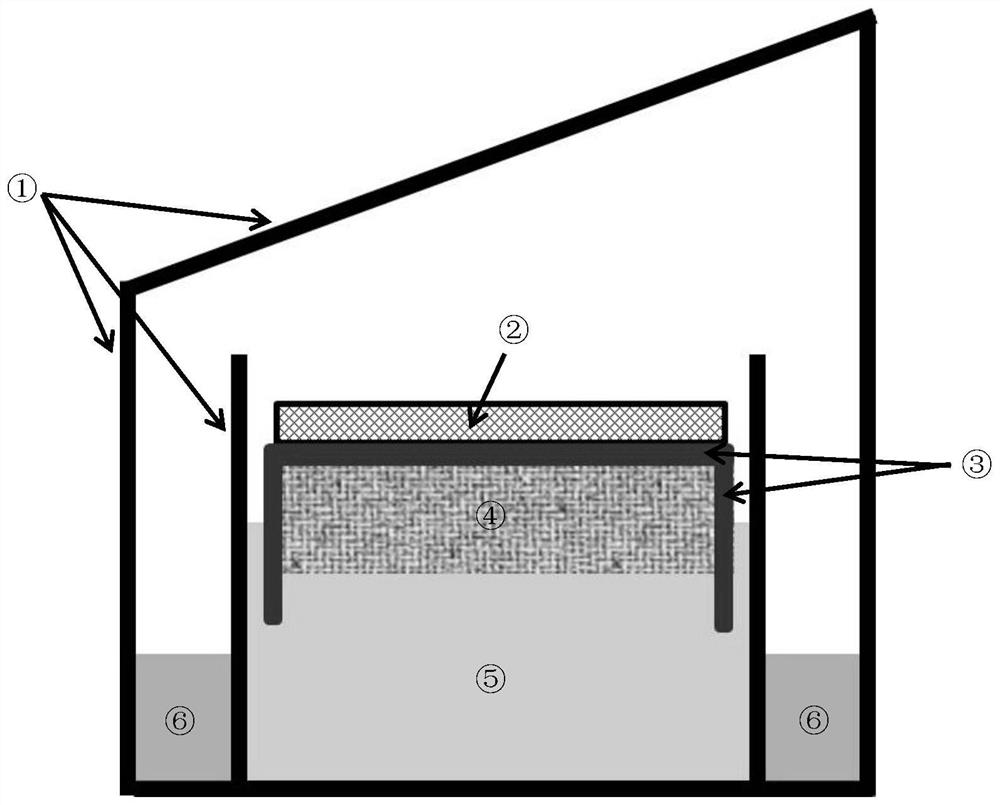

[0042] (4) the above Ag / TiO 2 The / MXene / SA assembly is placed on the absorbent fiber paper (absorbent material 3) in the landfill leachate treatment system, and the light intensity is 1500W / m 2 The above-mentio...

Embodiment 2

[0044] (1) Take 10mg Ti 3 C 2 Phase MXene was added to deionized water, and 2mg / mL MXene aqueous dispersion was prepared by ultrasonic dispersion; 30mg / mL AgNO was added dropwise at 1000rpm 3 Aqueous solution, in situ construction of Ag / TiO by redox reaction 2 / MXene composite catalyst, where AgNO 3 The mass ratio to MXene is 1:4.

[0045] (2) Add 20 mg of SA into deionized water, heat in a constant temperature water bath at 80°C, and stir magnetically to prepare a 4 mg / mL SA aqueous solution.

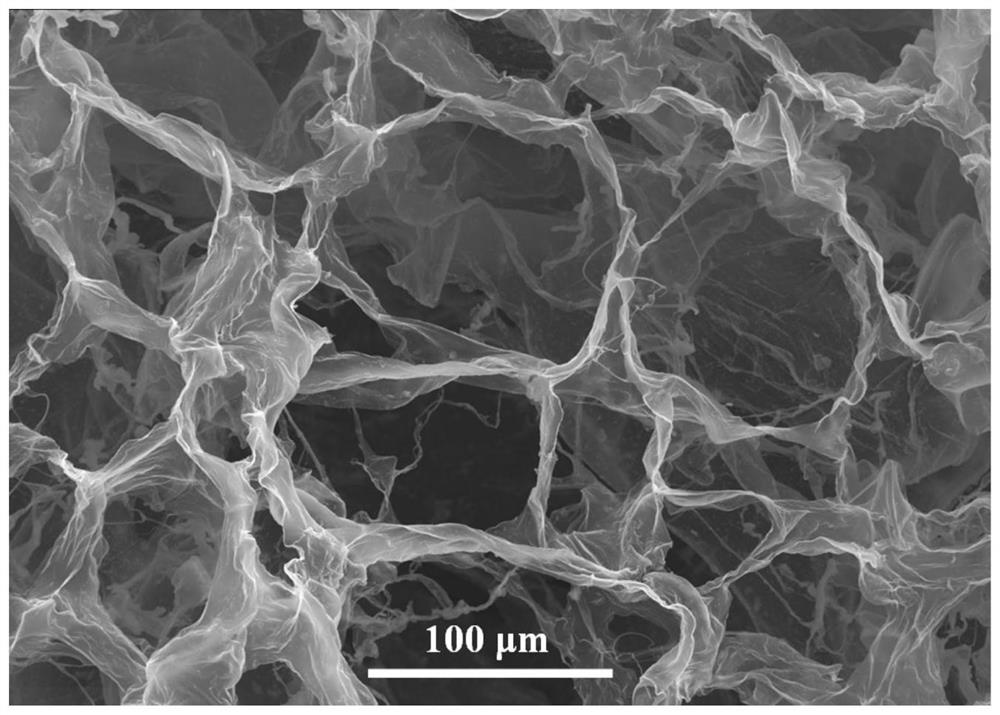

[0046] (3) 5mL of the Ag / TiO 2 / MXene dispersion and 5mL of the SA aqueous solution were mixed, stirred at 200rpm for 20min; 2 in a 100mL beaker, chemically crosslinked for 4h, then placed in liquid nitrogen for 10min, and then freeze-dried for 24h under vacuum to obtain a three-dimensional porous Ag / TiO 2 / MXene / SA assembly with an average pore size of 110 μm.

[0047] (4) the above Ag / TiO 2 The / MXene / SA assembly is placed on the absorbent fiber paper in the landfill leachate...

Embodiment 3

[0049] (1) Take 10mg Ti 3 C 2 Phase MXene was added to deionized water, and 2 mg / mL MXene aqueous dispersion was prepared by ultrasonic dispersion; 40 mg / mL AgNO was added dropwise at 500 rpm 3 Aqueous solution, in situ construction of Ag / TiO by redox reaction 2 / MXene composite catalyst, where AgNO 3 The mass ratio to MXene is 1:2.

[0050] (2) Add 40 mg of SA into deionized water, heat in a constant temperature water bath at 70°C, and magnetically stir to prepare an 8 mg / mL SA aqueous solution.

[0051] (3) 5mL of the SA aqueous solution and 5mL of the Ag / TiO 2 / MXene dispersion mixed, stirred at 200rpm for 15min; the above mixed solution was quickly poured into 2mL, 1wt% CaCl 2 in a 100mL beaker, chemically crosslinked for 2h, then placed in liquid nitrogen for quick freezing for 8min, and freeze-dried for 24h under vacuum to obtain Ag / TiO 2 / MXene / SA assembly.

[0052] (4) the above Ag / TiO 2 The / MXene / SA assembly is placed on the absorbent fiber paper in the landf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com