Heat-shrinkable multi-layered film

A shrinkable, multi-layer film technology, applied to layered products, synthetic resin layered products, identification devices, etc., can solve the problems of peeling off shrinkable labels, poor low-temperature shrinkage, and poor tearability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

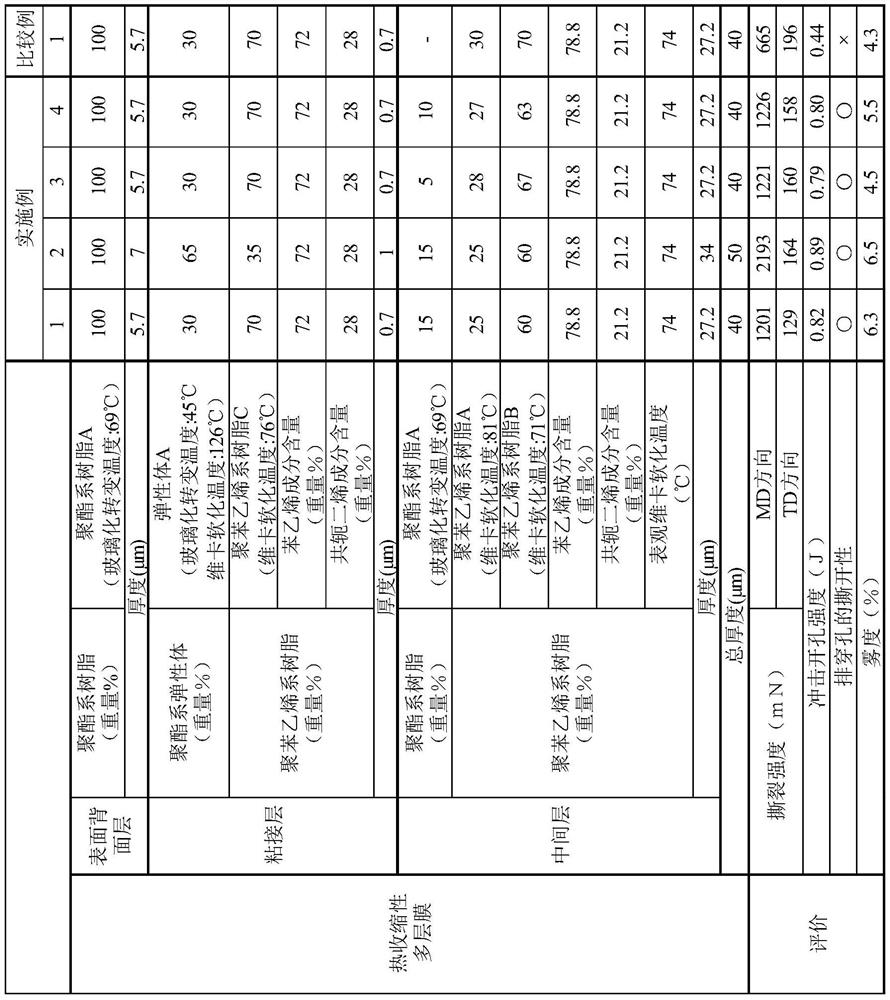

Embodiment 1

[0215] As the resin constituting the front and back layers, 100% by weight of polyester-based resin A was used.

[0216] As the resin constituting the adhesive layer, a mixed resin containing 30% by weight of the elastomer A and 70% by weight of the polystyrene-based resin C was used.

[0217] As the resin constituting the intermediate layer, a mixed resin containing 15% by weight of polyester-based resin A, 25% by weight of polystyrene-based resin A, and 60% by weight of polystyrene-based resin B was used.

[0218] These resins were put into an extruder with a barrel temperature of 160-250°C, extruded into a sheet with a 5-layer structure by a multi-layer die at 250°C, and cooled and solidified by a pulling roll at 30°C. Next, after stretching at a draw ratio of 6 times in a tenter stretching machine with a preheating zone of 105°C, a stretching zone of 90°C, and a heat setting zone of 85°C, it was coiled by a coiler to obtain a A heat-shrinkable multilayer film in which the...

Embodiment 2

[0221] As the resin constituting the front and back layers, 100% by weight of polyester-based resin A was used.

[0222] As the resin constituting the adhesive layer, a mixed resin containing 65% by weight of the elastomer A and 35% by weight of the polystyrene-based resin C was used.

[0223] As the resin constituting the intermediate layer, a mixed resin containing 15% by weight of polyester-based resin A, 25% by weight of polystyrene-based resin A, and 60% by weight of polystyrene-based resin B was used.

[0224] These resins were put into an extruder with a barrel temperature of 160-250°C, extruded into a sheet with a 5-layer structure by a multi-layer die at 250°C, and cooled and solidified by a pulling roll at 30°C. Next, after stretching at a draw ratio of 6 times in a tenter stretching machine with a preheating zone of 105°C, a stretching zone of 90°C, and a heat setting zone of 85°C, it was coiled by a coiler to obtain a A heat-shrinkable multilayer film in which the...

Embodiment 3

[0227] As the resin constituting the intermediate layer, a mixed resin containing 5% by weight of polyester-based resin A, 28% by weight of polystyrene-based resin A, and 67% by weight of polystyrene-based resin B was used, except that it was the same as in Example 1. operation to obtain a heat-shrinkable multilayer film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| tensile modulus | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com