Method and system for monitoring working temperature of spherical transducer

A technology of working temperature and transducer, which is applied to parts of thermometers, thermometers, and thermometers using electric/magnetic elements that are directly sensitive to heat, can solve the problem of not finding the same technology of the present invention, not finding the same method, temperature The sensor is not suitable for temperature monitoring of spherical piezoelectric ceramics, etc., to improve the temperature measurement accuracy, reduce the impact, and realize the effect of temperature warning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

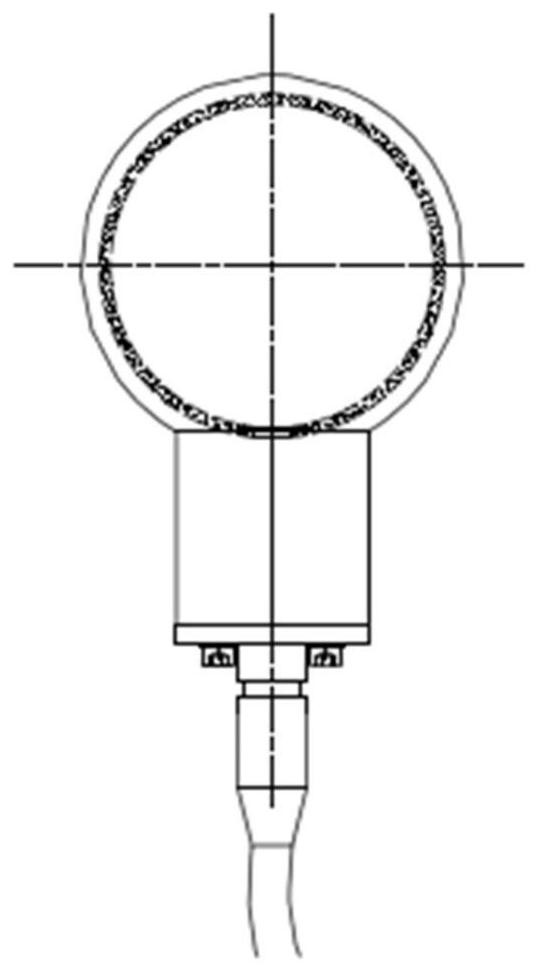

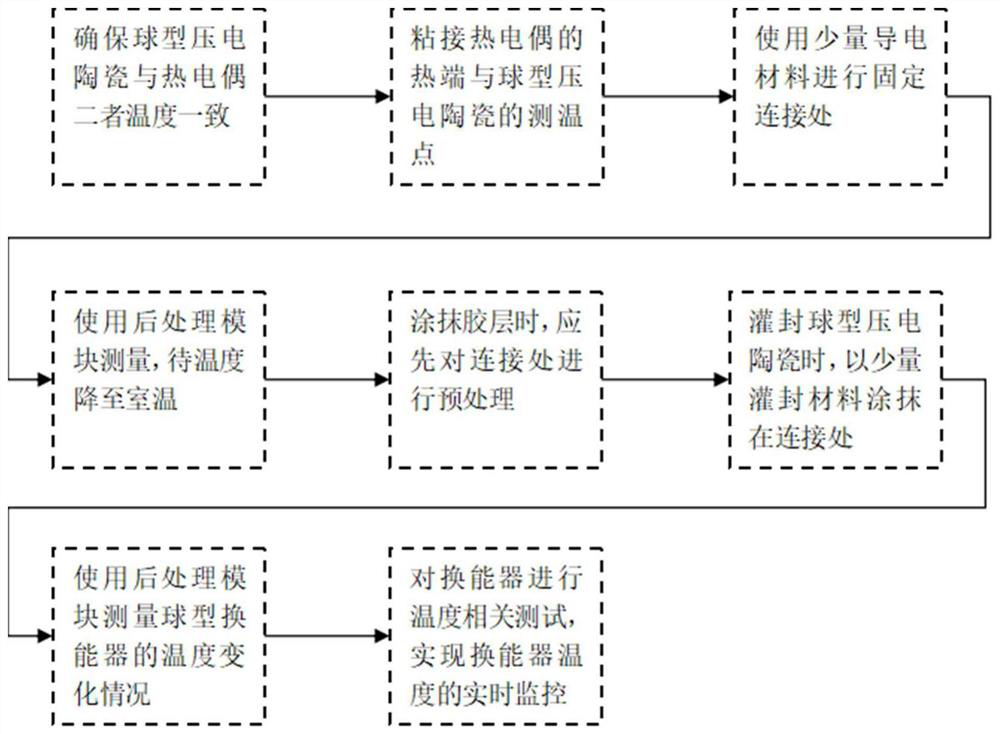

[0044] In this embodiment, a method for monitoring the operating temperature of a spherical transducer provided according to the present invention, such as image 3 As shown, specifically, in step 1, it will be as figure 2 The spherical piezoelectric ceramic and the K-type thermocouple shown in are placed at room temperature at the same time, and the temperature change of the two is accelerated by using a hair dryer or other equipment or left for a long enough time, so that the temperature of the spherical piezoelectric ceramic is the same as that of the K-type thermocouple. The temperature of the pair is the same.

[0045] In step 2, use solder to weld or use an adhesive layer with better thermal conductivity to bond the hot end of the K-type thermocouple and the temperature measuring point of the spherical piezoelectric ceramic to ensure that the hot end potential of the K-type thermocouple can be better It changes with the temperature change of the temperature measuring p...

Embodiment 2

[0053] This embodiment is based on embodiment 1, optimizes and implements in the following five aspects:

[0054] (1) In order to reduce the influence of the measurement response time, this embodiment selects a K-type thermocouple with a small diameter at the measuring end for the test, and selects an adhesive layer with better thermal conductivity to bond the piezoelectric ceramic ball and the thermocouple of the K-type thermocouple. end, so that the thermal response time is shortened, and the measured object and the temperature measuring element are more likely to achieve thermal equilibrium, so that the measurement accuracy of the present invention is increased.

[0055] (2) In order to reduce the influence of the temperature measurement point deviation on the measurement, in this embodiment, the point where the heat generation phenomenon is more obvious in the transducer is selected as the temperature measurement point. The position of the temperature measurement point mus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com