Low-hardness easily-reworked single-component heat-conducting gel and preparation method thereof

A low-hardness, one-component technology, applied in chemical instruments and methods, heat exchange materials, etc., can solve the problems of limited application scope, difficult to repair, large amount of residual glue, etc., to achieve high transparency, low surface tension, hydrophobicity good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

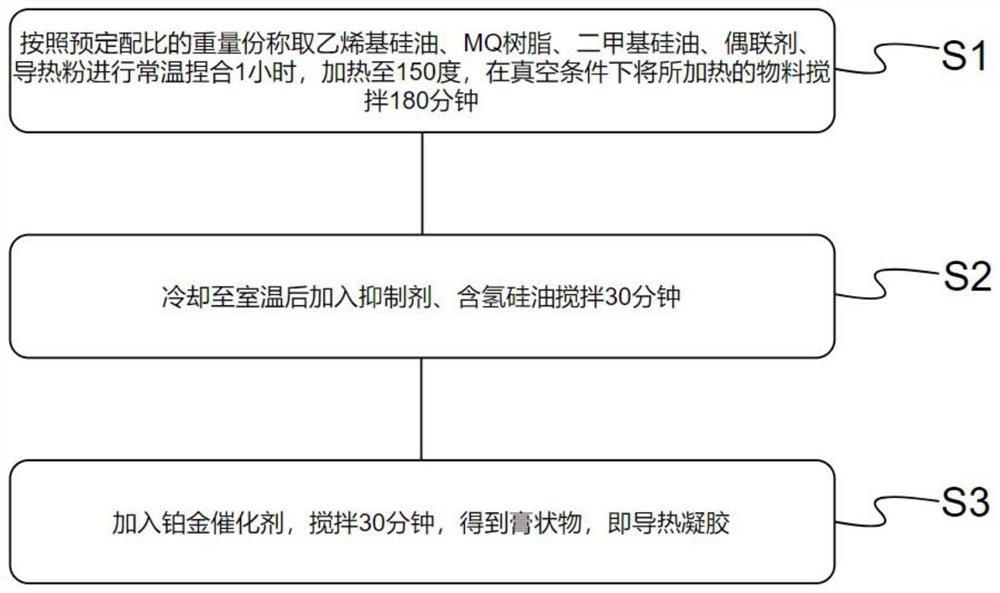

[0023] refer to figure 1 , which shows a flow chart of the steps of an embodiment of the preparation method of a low-hardness and easy-to-rework one-component thermally conductive gel of the present invention, which may specifically include the following steps:

[0024] S1. Weigh vinyl silicone oil, MQ resin, dimethyl silicone oil, coupling agent, and heat conduction powder according to the predetermined proportion by weight, knead at room temperature for 1 hour, heat to 150 degrees, and stir the heated materials under vacuum conditions 180 minutes;

[0025] S2, after cooling to room temperature, add inhibitor and hydrogen-containing silicone oil and stir for 30 minutes;

[0026] S3, adding the platinum catalyst and stirring for 30 minutes to obtain a paste, that is, a thermally conductive gel.

[0027] In the above steps, the thermally conductive gel includes, in parts by weight: 1-10 parts of vinyl silicone oil, 0.1-2 parts of MQ resin, 1-12 parts of dimethyl silicone oil,...

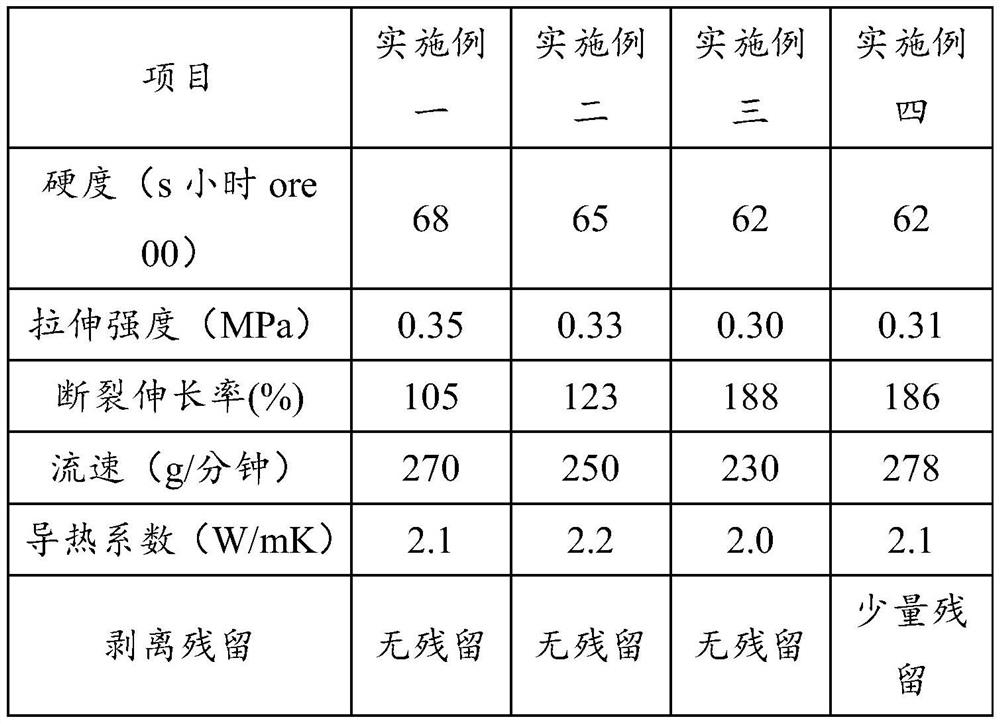

Embodiment 1

[0029] Weigh 6 parts of vinyl silicone oil with a viscosity of 5000mPa.s, 0.3 parts of MQ resin with a viscosity of 100mPa.s, 6 parts of dimethyl silicone oil with a viscosity of 100mPa.s, and 0.15 parts of hexadecyltrimethoxysilane. 30 parts of alumina with a diameter of 1 μm, 50 parts of alumina with a particle size of 5 μm, and 20 parts of alumina with a particle size of 20 μm, kneading at room temperature for 1 hour, then heating the material to 150 degrees, vacuuming until the vacuum degree reaches -0.1MPa, and continuing Stir for 180 minutes. After the stirring was completed, the mixture was cooled to room temperature, 2 parts of side-chain hydrogen-containing silicone oil with a hydrogen content of 0.18%, and 0.03 part of acetylene cyclohexanol were added, and stirring was continued for 30 minutes. Finally, 2000 ppm of microcapsule-type platinum catalyst (based on the mass of platinum) was added and stirred for 30 minutes, and the obtained paste was the finished heat-co...

Embodiment 2

[0031] Weigh 5 parts of vinyl silicone oil with a viscosity of 50000mPa.s, 0.3 parts of MQ resin with a viscosity of 100mPa.s, 7 parts of dimethyl silicone oil with a viscosity of 100mPa.s, and 0.15 parts of hexadecyltrimethoxysilane. 30 parts of alumina with a diameter of 1 μm, 50 parts of alumina with a particle size of 5 μm, and 20 parts of alumina with a particle size of 20 μm, kneading at room temperature for 1 hour, then heating the material to 150 degrees, vacuuming until the vacuum degree reaches -0.1MPa, and continuing Stir for 180 minutes. After the stirring was completed, the mixture was cooled to room temperature, 2 parts of side-chain hydrogen-containing silicone oil with a hydrogen content of 0.18%, and 0.03 part of acetylene cyclohexanol were added, and stirring was continued for 30 minutes. Finally, 2000 ppm of microcapsule-type platinum catalyst (based on the mass of platinum) was added and stirred for 30 minutes, and the obtained paste was the finished heat-c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com