Low-temperature fast-curing concrete and preparation method thereof

A rapid curing and concrete technology, which is applied in the field of concrete preparation, can solve the problems that the rapid curing and high strength of concrete cannot be balanced, and achieve the effect of promoting rapid curing, avoiding overheating or overcooling, and ensuring the strength of concrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

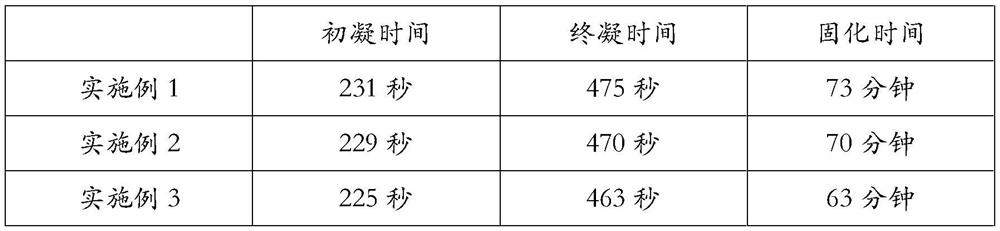

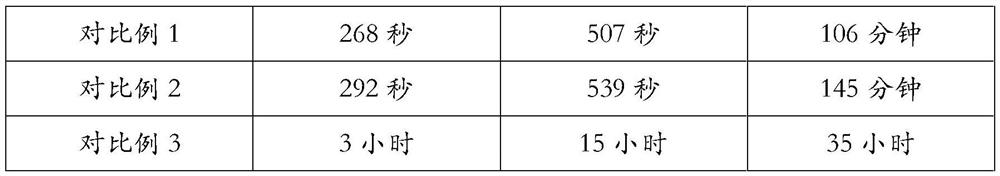

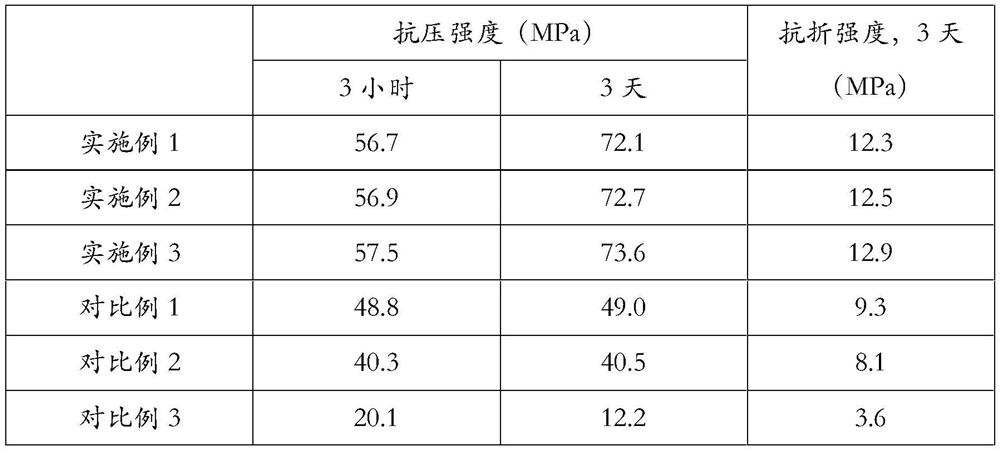

Examples

Embodiment 1

[0037] A method for preparing low-temperature fast-curing concrete. First, add 20kg of water to 350kg of aggregate, mix evenly to make the aggregate fully absorb water to obtain pre-treated aggregate, and then carry out coating treatment to obtain coated aggregate, and then coat the aggregate. The material is stirred and mixed with 100kg of cement and 0.8kg of water-reducing agent, and 35kg of water is added, and the slurry is obtained by stirring. The specific method is as follows:

[0038] (1) First, butyl dichloroborane, methyldichlorosilane, and hexamethyldisilazane are prepared into corresponding solutions; and tertiary vinyl carbonate, 1H, 1H, 2H-perfluoro-1 - Decene, emulsifier and water are formulated into a premix;

[0039] (2) then dropping butyldichloroborane and methyldichlorosilane solution into hexamethyldisilazane solution simultaneously, then adding pretreated aggregate and premixed liquid, stirring reaction to obtain precursor;

[0040] (3) Finally, under am...

Embodiment 2

[0054] A method for preparing low-temperature fast-curing concrete. First, add 25kg of water to 450kg of aggregate, mix evenly to make the aggregate fully absorb water to obtain pre-treated aggregate, and then carry out coating treatment to obtain coated aggregate, and then coat the aggregate. The material is stirred and mixed with 100kg of cement and 1kg of water-reducing agent, and 40kg of water is added, and the slurry is obtained by stirring. Methods as below:

[0055] (1) First, butyl dichloroborane, methyldichlorosilane, and hexamethyldisilazane are prepared into corresponding solutions; and tertiary vinyl carbonate, 1H, 1H, 2H-perfluoro-1 - Decene, emulsifier and water are formulated into a premix;

[0056] (2) then dropping butyldichloroborane and methyldichlorosilane solution into hexamethyldisilazane solution simultaneously, then adding pretreated aggregate and premixed liquid, stirring reaction to obtain precursor;

[0057] (3) Finally, under ammonia atmosphere an...

Embodiment 3

[0071] A method for preparing low-temperature fast-curing concrete. First, add 22 kg of water to 400 kg of aggregate, mix well so that the aggregate can fully absorb water to obtain pre-treated aggregate, and then carry out coating treatment to obtain coated aggregate. The material is stirred and mixed with 100kg of cement and 0.9g of water-reducing agent, 38kg of water is added, and the slurry is obtained by stirring. The specific method is as follows:

[0072] (1) First, butyl dichloroborane, methyldichlorosilane, and hexamethyldisilazane are prepared into corresponding solutions; and tertiary vinyl carbonate, 1H, 1H, 2H-perfluoro-1 - Decene, emulsifier and water are formulated into a premix;

[0073] (2) then dropping butyldichloroborane and methyldichlorosilane solution into hexamethyldisilazane solution simultaneously, then adding pretreated aggregate and premixed liquid, stirring reaction to obtain precursor;

[0074] (3) Finally, under ammonia atmosphere and stirring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com