Preparation method for softening and bending wood

A technology of wood and bending, which is applied in the field of preparation of wood softening and bending, can solve the problems of difficult fiber regulation and complex wood structure, and achieve the effects of increased fatigue limit, wide range of curvature and improved plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The invention provides a method for preparing wood softening and bending, which specifically includes the following steps:

[0031] (1) Treating the wood with the treatment solution A for 20 minutes to 72 hours to remove part of the lignin, and the removed lignin content is 10%-99%. Lignin mainly exists between fibers, which can connect cells and fibers and provide rigid support for wood. After removing part of the lignin, it can not only destroy the chemical bond between lignin and cellulose, but also provide space for the subsequent swelling and migration of cellulose fibers.

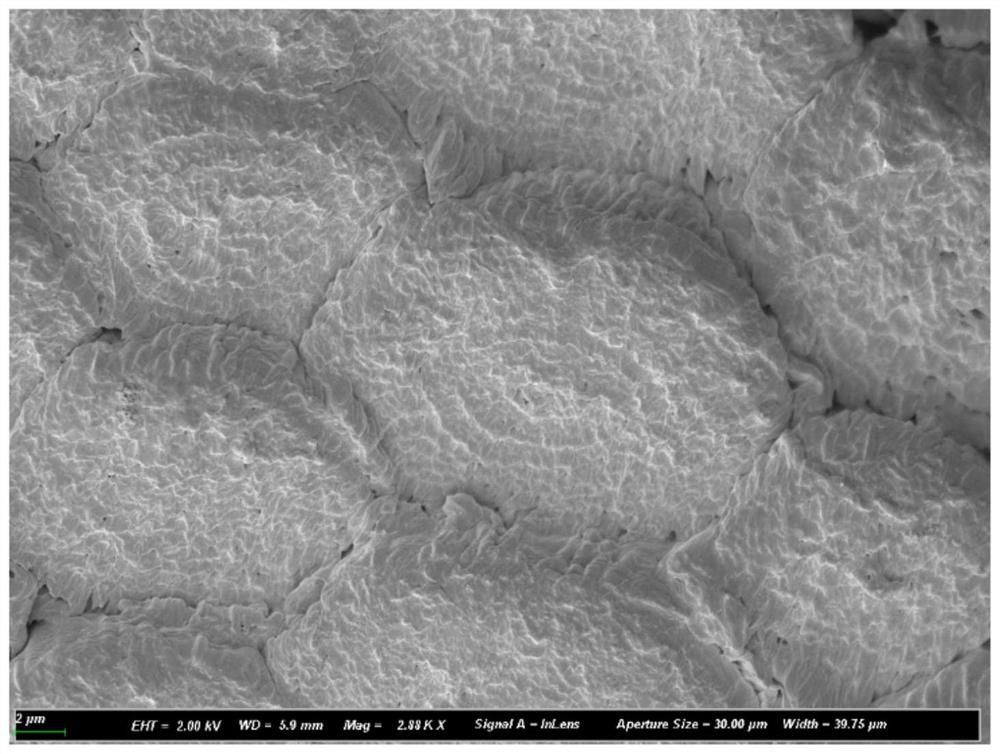

[0032] (2) The wood obtained in step (1) is treated with N,N dimethylacetamide and lithium chloride solution, so that the nanofibers in the wood swell and slide, and evenly fill in the hollow cell lumen of the wood.

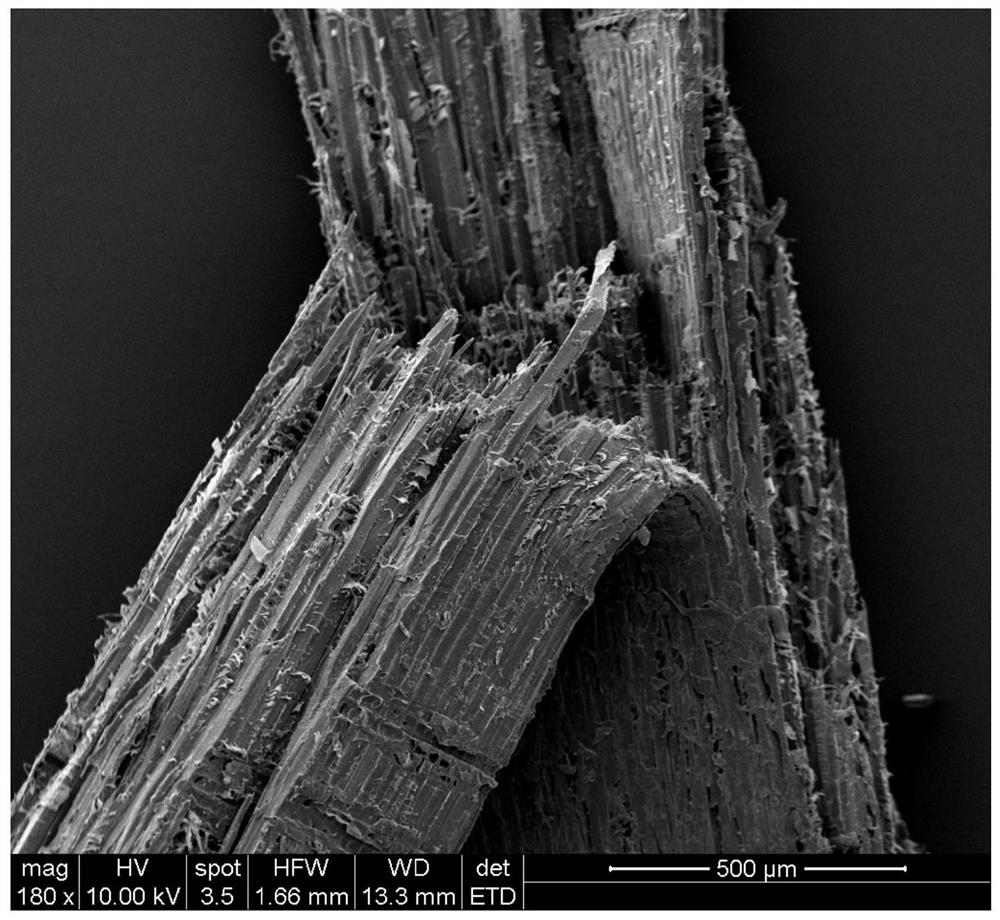

[0033] The original wood structure before solution treatment as figure 1 As shown, the original wood exhibits rigid characteristics when bent, does not have plasticity and elast...

Embodiment 1

[0038] Basswood with a height of 70cm and a diameter of 1mm was placed in 2.0mol / L sodium hydroxide and 0.03mol / L sodium sulfite aqueous solution for 10 hours, and the excess chemicals were washed with water, and then dried. Then put in N,N-dimethylacetamide solution, keep at 160°C for 60 minutes, then cool to 110°C, add a certain amount of lithium chloride, lithium chloride: the mass of N,N-dimethylacetamide solution Ratio = 1:8, react for 60 minutes, take it out, let it stand for 24 hours, immerse in water for 10 hours, and then wash it with deionized water several times. At this time, the wood can be bent, even knotted, and can be set when dry. The schematic diagram of its knotted wood is shown in figure 1 , and by Figure 6 It can be seen that its tensile strength along the grain is 430MPa, which is nearly 7 times that of the original wood.

Embodiment 2

[0040] Cut pine sylvestris crosswise into thickness 3mm and diameter 10cm, put it in 2.0mol / L sodium hydroxide, 0.03mol / L sodium sulfite aqueous solution and cook for 10 hours, wash excess chemicals with water, and then dry. Then put in N,N-dimethylacetamide solution, keep at 165°C for 30 minutes, then cool to 120°C, add a certain amount of lithium chloride, lithium chloride: the mass of N,N-dimethylacetamide solution Ratio = 1:9, react for 40 minutes, take it out, let it stand for 10 hours, soak it in water for 5 hours after taking it out, and then wash it with deionized water for many times. At this time, the wood can be bent and dried into a shape Figure 4 Shown, and the tensile strength along the grain is 423MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com