A polishing machine with functions of in-situ measurement and trimming of disk surface

A polishing machine and disk surface technology, applied in surface polishing machine tools, grinding/polishing equipment, manufacturing tools, etc., can solve problems such as inaccurate measurement results, and achieve increased complexity, uniform removal rate distribution, and accurate processing stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

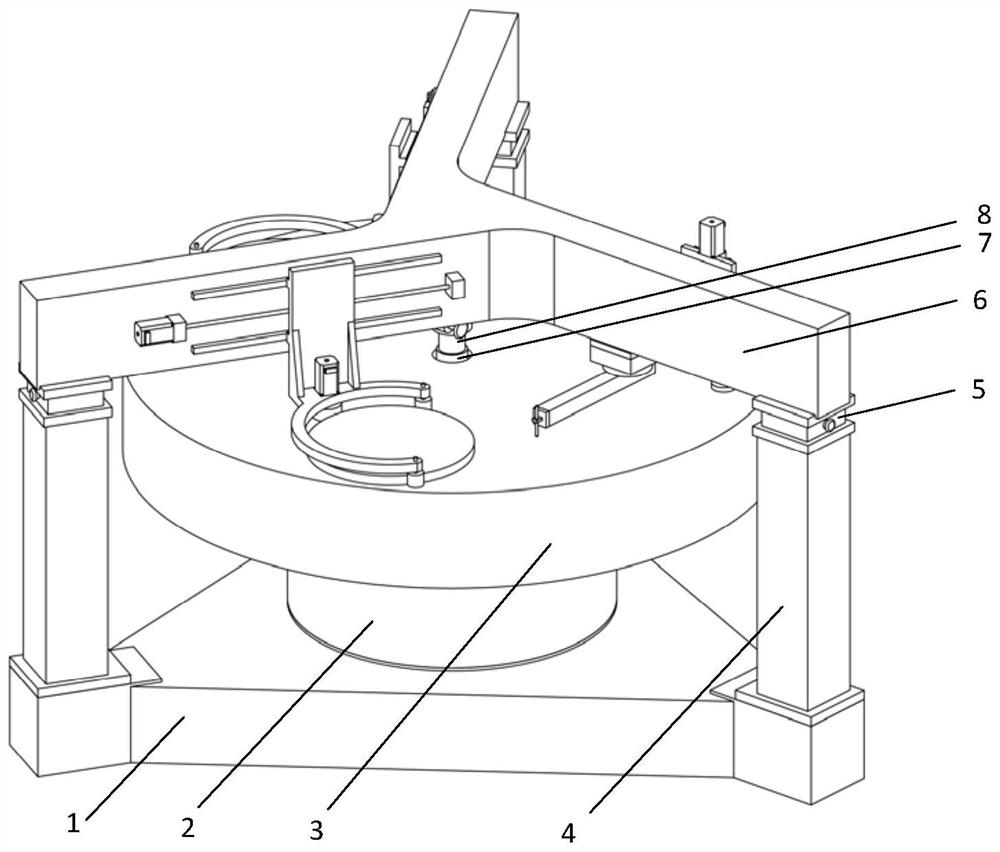

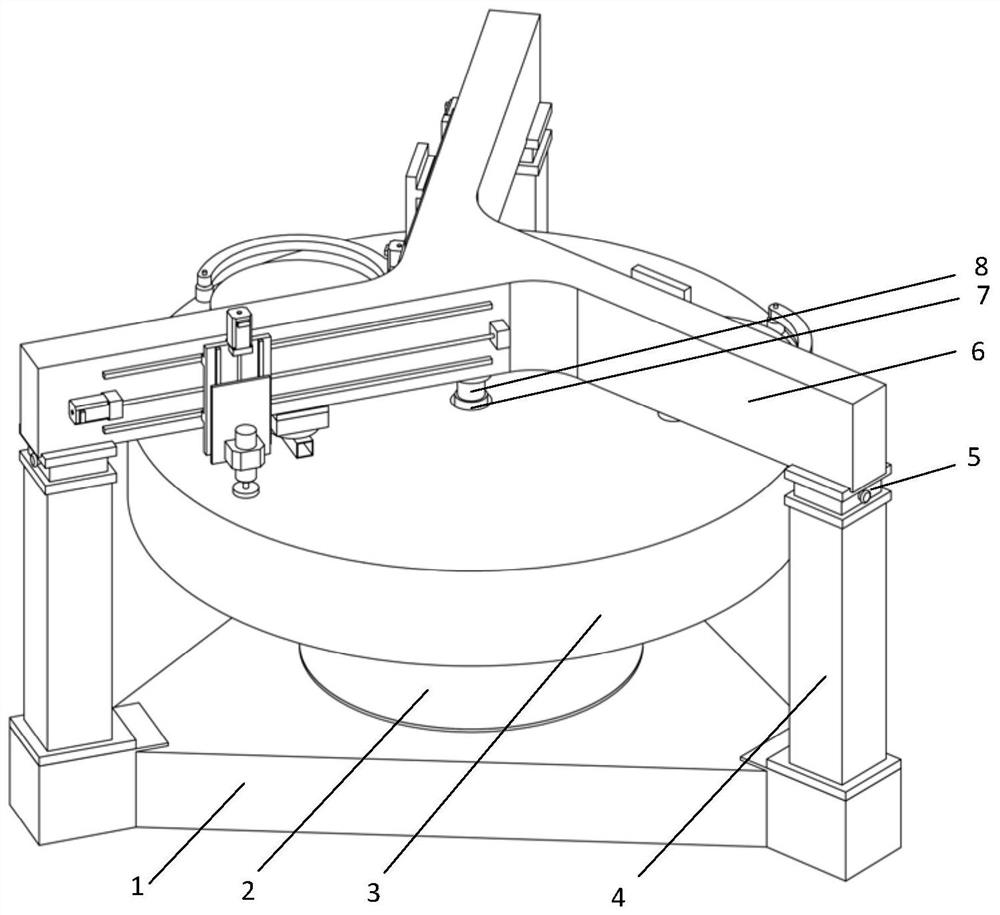

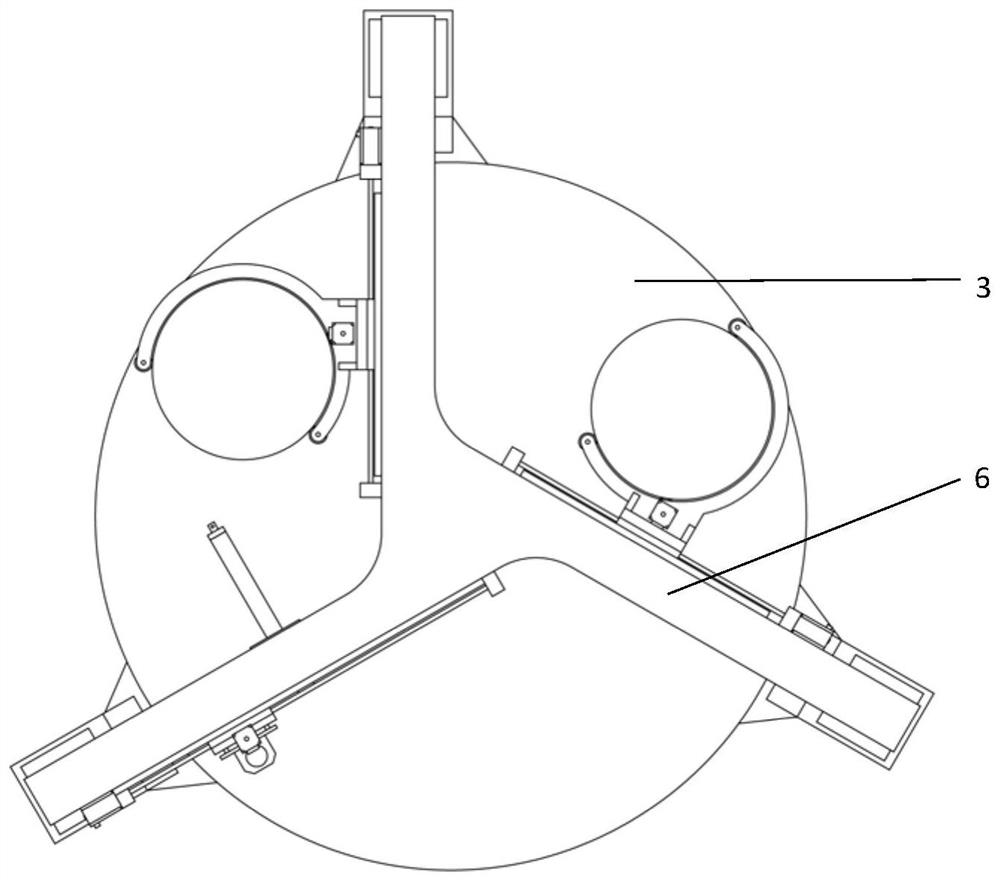

[0038] The present invention will be further described below in conjunction with the accompanying drawings. Such as Figure 1-11 As shown, a polishing machine with in-situ measurement and trimming functions of the disc surface includes a base 1, a spindle 2, a polishing disc 3, a support unit, a feed unit, a measuring unit, a trimming unit and a computer; the base 1 is a triangular shape Structure, the upper surface has four mounting surfaces, which are machined in one pass, one of which is located in the center for the spindle 2, and the remaining three mounting surfaces are located at the three corners for mounting the support unit ; The diameter of the polishing disc 3 is greater than or equal to 20000mm, installed above the main shaft 2 and coaxial with the main shaft 2, and the main shaft 2 provides power for the rotation of the polishing disc 3;

[0039] The feeding unit, measuring unit and trimming unit are respectively installed on the supporting unit;

[0040]The su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com