A carbon brush lead wire and connecting bridge welding device

A welding device and connecting bridge technology, applied in welding equipment, auxiliary devices, manufacturing tools, etc., can solve problems such as low operating efficiency, lack of suitable fixtures between carbon brushes and connecting bridges, unstable welding and assembly quality, etc., and achieve improvement Operational efficiency, improvement of welding operation efficiency, and effect of improving welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

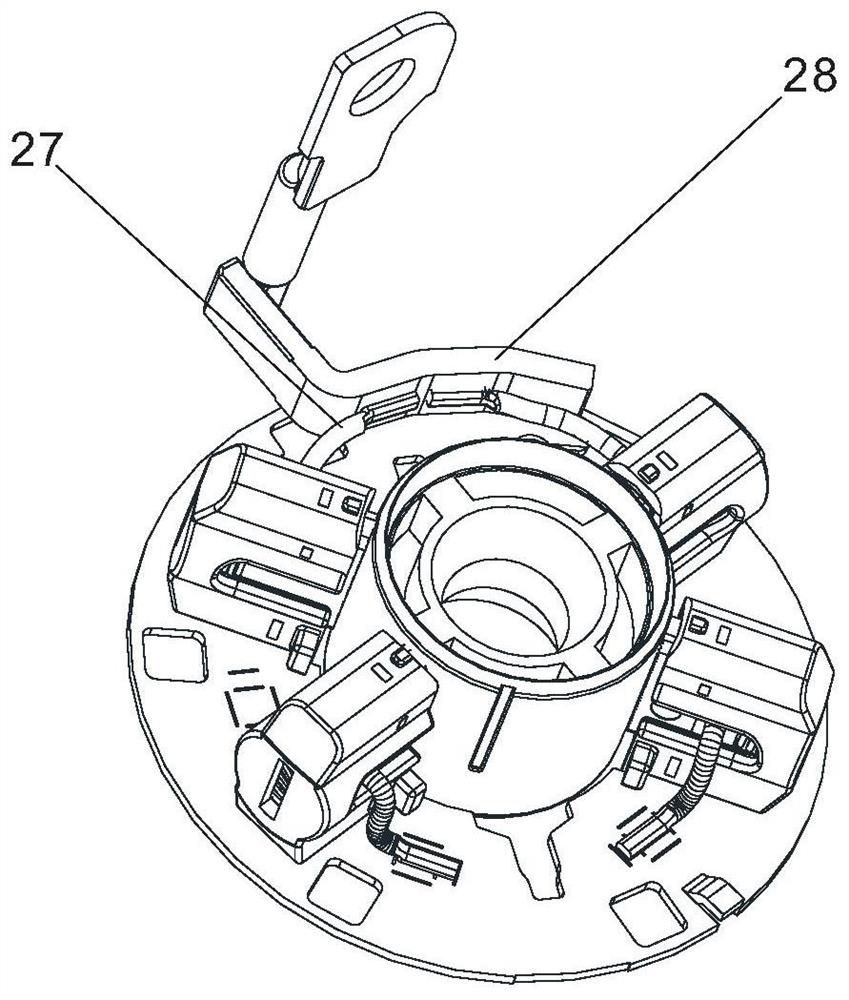

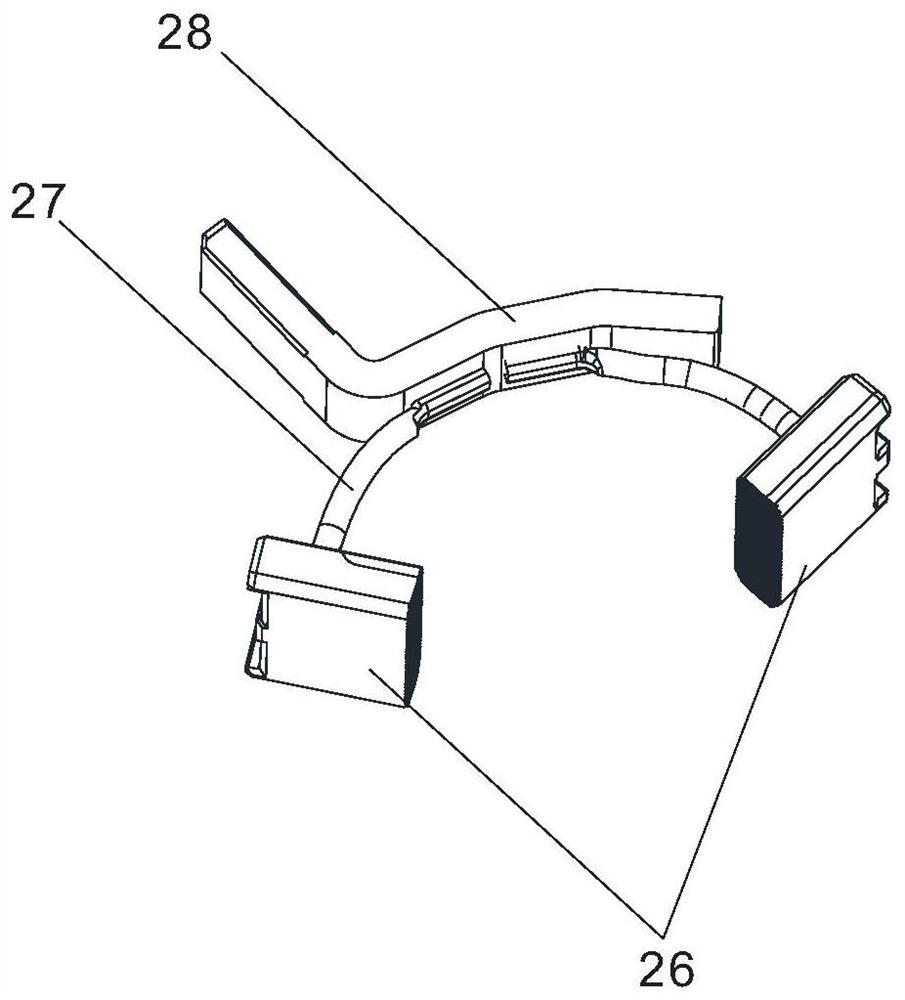

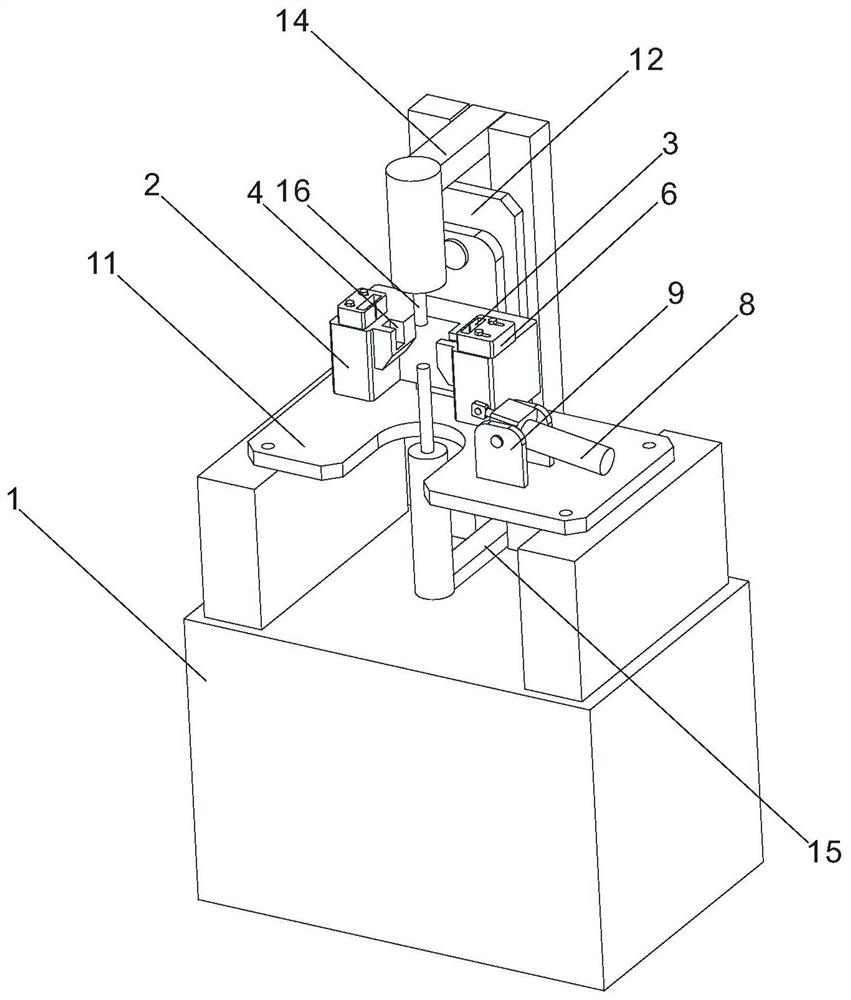

[0025] Such as image 3 , Figure 4As shown, a carbon brush lead wire and connecting bridge welding device includes a machine base 1, and also includes a welding mechanism, a welding piece positioning mechanism and a welding spot transfer mechanism. The welding mechanism, the welding piece positioning mechanism and the welding spot transferring mechanism are arranged on the machine base. 1. The welding part positioning mechanism is used to keep the relative position of the carbon brush and the connecting bridge to be welded fixed. The welding spot transfer mechanism is connected with the welding part positioning mechanism and can drive the welding part positioning mechanism to change the position so that the carbon brush lead wire and the connecting bridge are connected. Each of the to-be-welded points corresponds to the welding mechanism respectively. The weldment positioning mechanism includes a welding piece positioning seat 2, a pair of carbon brush positioning grooves 3 ...

Embodiment 2

[0028] Such as Figure 5 , Figure 6 As shown, a pendant rod support plate 17 is welded to the middle part of the top of the weldment positioning seat 2, and a horizontal transverse groove 18 is provided on the pendant pole support plate 17, and a mounting roller is arranged in the horizontal transverse groove 18, and the mounting roller A pendant bar 19 is hinged on the top, and a crimping part 20 is slidably connected on the pendant bar 19, and a back-moving spring is connected between the crimping part and the pendant bar 19. The upper welding arm 14 is fixedly provided with a left and a right two can During the descending process, the upper welding arm 14 touches the pressing bar 21 of the pressing wire member, and the pressing bar 21 is symmetrically located on both sides of the welding electrode head 16 . The crimping member 20 includes a crimping slider, a briquetting block 23 and a crimping roller 25. The hanging rod 19 is provided with an axial chute 22, and the crim...

Embodiment 3

[0031] The crimping part 20 includes a collar, a pressing block and a crimping roller. The collar is slidably sleeved on the pendant rod 19. An anti-rotation key bar is provided on the inner wall of the collar, and an axial chute is provided on the pendant rod 19. , the anti-rotation key bar is slidably embedded in the axial slide groove, the pressure block is fixedly connected to the collar, the top of the pressure block is provided with a wedge-shaped guide groove, the bottom end of the pressure rod is wedge-shaped to match the wedge-shaped guide groove, and the pressure wire roller The shaft is rotatably connected to the bottom of the pressing block. All the other are with embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com